Backscatter shows POF defects

Incorporating news from O plus E magazine, Tokyo

YOKUSUKAResearchers at Optowave Laboratory Inc. have successfully detected backscattering approximately 125 m from the input end of a plastic optical fiber (POF). Backscattering in the form of Rayleigh scattering is currently used in the detection of defects in glass optical fibers. The associated measurement technique, optical time-domain reflectometry, can determine the location and severity of cuts and breaks. However, although POFs exhibit Rayleigh scattering, defect detection cannot currently be done using this method because the plastic itself has a large loss. Also, most POFs are designed for short-distance use. Most recently, however, POFs are being developed with lower loss and an extended transmission range so it will become necessary to test for defects.

Defects are found by sending light into one end of the fiber and taking time-resolved measurements of the backscattered light from the same end of the fiber. Polymethylmethacylate POF at 650 nm (a wavelength commonly used in POF links) has a loss that is attributed mostly to carbon-hydrogen high-frequency absorption, rather than Rayleigh scattering or loss due to structural imperfections. Thus, there is little backscattering. For this reason, the light was detected in this experiment by using a photon-counting method that includes a highly sensitive optical electron amplifier tube with a large surface area.

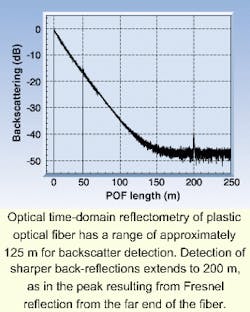

The light source was a pulsed laser diode having a pulse width of 1 ns. The 200-m-long POF was made by Mitsubishi Rayon Co., Ltd. (Tokyo). Both backscattering up to 125 m and Fresnel reflection at the end of the 200-m fiber were detected (see figure). The dynamic range of the measurement system reached to greater than 40 dB. Measurements made after defects (pins) were inserted into the fiber at 10, 11, 11.5 and 12 m showed a spatial resolution of 50 cm.

By increasing measurement time and pulse width and thus the energy of the incident light, the detection range should increase from 125 up to 200 m. In addition, the spatial resolution can be improved to 10 cm by decreasing the jitter of the detector system and the pulse width of the light source.

Courtesy O plus E magazine, Tokyo