Hollow-core fibers deliver ultraviolet light without solar degradation

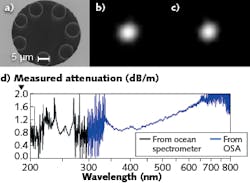

In one AR-HCF configuration, a 109-µm-diameter silica tube includes seven interior capillary tubes nearly equidistantly spaced in the core with individual core wall thickness and inner diameter averaging 132 nm and 7.3 µm, respectively. The AR-HCF capillary tubes act as resonant cavities, guiding the light within the core rather than in the solid silica cladding, significantly reducing attenuation and solarization while increasing optical-damage thresholds. For this fiber, the attenuation at a deep-UV wavelength of 218 nm is 0.1 dB/m—significantly lower than fused silica glass. Another AR-HCF optimized for 266 nm laser delivery produces nearly circular near-field pattern images even after 19.8 m transmission distances. Calculated attenuation values are 0.7 and 0.83 dB/m for 263.7 and 380 nm UV transmission wavelengths, respectively, without requiring hydrogen passivation. Reference: F. Yu et al., Opt. Express, 26, 8, 10879–10887 (2018); https://doi.org/10.1364/oe.26.010879.

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.