Japanwatch

Reticle pattern generator writes 90-nm features

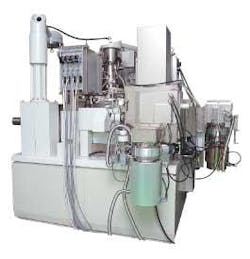

TOKYO—Engineers at JEOL have developed new electron-beam drawing apparatus for mass production of next-generation lithographic photomasks, or reticles, with features down to 90 nm (see figure). To aid with the miniaturization of semiconductor integrated-circuit elements, which are patterned at ever-shorter exposure wavelengths, demand has been increasing for reticles with finer resolutions. The new electron-beam apparatus makes possible high-resolution, high-throughput production of reticles by improving the electro-optic systems and material carrier systems and increasing the critical-dimension (CD) resolution and position resolution.

The electron-gun emitter uses single-crystal lanthanum hexaboride and has an acceleration power of up to 50 kV. The CD resolution is 8 nm (3s) and the position resolution is ±12 nm.

As the minimum feature size in large-scale integrated circuits gets smaller, the amount of information in photomasks increases. This new device copes with this increase in information by increasing data-processing speed and transmission speed by an order of magnitude, and by increasing the current density of the electron beam.

Courtesy O plus E magazine, Tokyo

Midspan spectral inverter rebuilds signal

TOKYO—Shinji Yamashita of the University of Tokyo Graduate School of Frontier Sciences has developed a low-noise wavelength-division-multiplexing application using a midspan spectral inverter (MSSI) with a high-efficiency nonlinear four-wave-mixing device.

Four-wave mixing involves pumping light of a different wavelength along with a signal being transmitted through an optical fiber. The result is that a new signal is generated with some properties opposite to that of the original signal. Usually, pulses degrade as they are transmitted along an optical fiber, with a decay distance dependent on the wavelength of the light. In this research, a wavelength-conversion device that can efficiently perform four-wave mixing was placed in the transmission path. The signal light was modulated in addition to the pump light. As a result, the signal-generation efficiency increased and the spreading of the spectrum was controlled. The receiving end could thus receive a good signal with little dispersion.

A 1559.31-nm, 9.95328-GHz non-return-to-zero signal was transmitted over 203.8 km (see figure). The light was wavelength-modulated at a 100-km distance down the fiber. The pumping light for the four-wave mixing was 1554 nm, and 1548.69 nm after modulation. As a result of this setup, the signal waveform—which was temporarily deformed—was successfully restored to its original shape (see figure).

In this experiment, the spectrum-inversion properties of the optical fiber four-wave-mixing wavelength modulator were exploited. In the future, the wide bandwidth properties of this device will be used to create a pure wavelength modulator.

Courtesy O plus E magazine, Tokyo