Select the right test equipment for your fiberoptic needs

The importance of fiberoptic networks is evident by their proliferation throughout business and industry for data transfer, local- and wide-area communications, and control signaling. The advent of the portable optical time domain reflectometer (mini-OTDR) has allowed fiberoptic network users to have high-accuracy measurement of a variety of cable characteristics in packages that are easily transported and used in the field. These OTDRs and other types of reflectometers, in conjunction with more traditional optical power meters and other devices, help to determine installed fiber characteristics relative to system specifications. This equipment also aids in optimizing performance for maximum data transfer and pinpointing system faults for timely correction. Test instrumentation can also be used to certify and maintain system components such as lasers, couplings, and connectors (see "Fiber basics dictate testing needs," p. 162).

This Product Focus is meant to be representative of the fiberoptic test equipment on the market. The manufacturers` listing that follows on p. 172 highlights some of the many available OTDRs. It is not a comprehensive inventory. For a detailed listing of manufacturers and suppliers of fiberoptic test equipment see the 1995 Laser Focus World Buyers Guide, pp. 396-400. Prospective buyers should contact individual vendors for full information on product lines.

Finding faults

An OTDR is one of the main pieces of fiberoptic test equipment in which miniaturization has allow technicians laboratory accuracy in field trouble-shooting situations (see figure). The instrument works somewhat like a light-based radar system. A pulse of laser light is launched through a beamsplitter down a fiber. The time history of the reflected and backscattered light sent back along the fiber through the beamsplitter to an avalanche photodiode detector indicates system characteristics and condition. Because energy entering the detector can be low, repeated measurements are made and the signal-to-noise ratio improved by averaging readings for data display.

The OTDR display plots power, in decibels, on the vertical scale against time. By correlating the time of each detected event with distance, the location of breaks and other faults, as well as system features and their performance, can be determined. A discontinuity, such as a connector, registers as a "spike" in the power reading. This apparent power increase is caused by the energy of Fresnel reflections being greater than the Rayleigh backscattering. After the reflection increase, a connector trace will exhibit a drop from losses across the joint. A quality splice trace should have no spike and a slight drop in power. Because an individual fiber may be braided around a cable or core, the true fiber length indicated by the OTDR is actually longer than the cable length.

Dynamic range of an OTDR defines the maximum and minimum power to the detector. The dynamic range, along with the fiber attenuation and losses, the source wavelength, and pulsewidth, determines the useful fiber-length range, at which the backscattered light drops into the noise level. Typical fiber attenuation values are 0.25-0.35 dB/km for single-mode fiber and 1.0-2.7 dB/km for multimode. The lower attenuation for single-mode fiber contributes to its usefulness in long-range telecommunications.

Resolution of single-point features refers to being able to detect a fiber fault and relates to the sampling resolution. Spatial resolution is the ability to distinguish two faults close to one another. Pulsewidth of the OTDR and detector bandwidth determine spatial resolution. Accuracy of OTDR distance measurements hinges on the index of refraction value obtained from the fiber manufacturer and horizontal linearity of the OTDR display.

When a Fresnel reflection occurs from the OTDR bulkhead connector to the test fiber or any other connections along its length, a dead zone is created. Much like the effect of a camera flash on the human eye, the burst of light from the reflection saturates the detector for several microseconds before the device recovers. Other faults within this region of the trace are thus hidden.

There are several ways to reduce dead-zone effects, although they cannot be completely eliminated because even the narrowest source has a finite pulsewidth. One technique is to optically mask the detector by switching the reflected energy away from it at the appropriate time to preclude saturation. Source laser power can be also reduced but this reduces dynamic range and distance capability.

The effect of the initial light-launch dead zone can be mitigated by installing a calibrated test-fiber box with sufficient length of fiber between the OTDR and the test-fiber connection. Or, if the fiber is accessible, an OTDR can test it from the other end. Visual fault locators, like those made by Siecor (Hickory, NC), use a visible-wavelength, 650-nm laser to locate faults near fiber endpoints.

In practical terms, high launch losses can be caused by a contaminated OTDR connection. With a single-mode fiber, a single speck of dirt can cover the core. The OTDR input and test-fiber diameters should also be the same. Similarly, if fibers with different diameters, indices of refraction, attenuation, and so forth, are spliced together, an OTDR trace may exhibit a gain rather than a loss. This apparent "amplification" is due to increased backscatter from the change in core characteristics. The fiber should be tested from the opposite end and the splice effects averaged.

Before fiberoptic systems are installed, an OTDR can determine if cabling complies with specifications. After hookup, any faults incurred during installation can be found and corrected and the system documented for future performance comparison or troubleshooting.

While versatile, OTDRs are not the only fiberoptic test tools. The driving characteristic of optical fiber, end-to-end attenuation, can be determined with a basic optical power meter and a light source. Modern meters incorporate multiple references, interchangeable connector adapters, backlit displays for use in darkened wiring closets, and shielding from the radio-frequency effects of computers and other electronics. Some multimeter units combine several source and meter function ports. Such devices can measure component characteristics including coupling ratios, insertion losses, and polarization characteristics.

With such basic equipment, a cable can be tested fiber by fiber for any out-of-spec links then evaluated with an OTDR for loss cause, location, and correction. Some systems even combine power-meter and visual-fault-finding functions with OTDR capabilities. Data storage and handling capacity of such equipment also aids in management and documentation of growing numbers of extensive fiber-cable systems.

Other fiberoptic test equipment includes optical attenuators used to analyze network components and devices. An attenuator permits decreases in an output signal, simulating network losses, to find the power level at which transmission quality becomes unacceptable. For digital applications this criterion is the bit-error rate; in analog applications, such as television, bandwidth modulation is crucial, showing up as picture quality. In addition, attenuator output can be used to monitor source power fluctuations.

Compared with electronic systems and equipment, fiberoptic cable offers data and communication links with higher bandwidths, lower attenuation losses, immunity to electromagnetic interference, and greater security. But as one fiberoptic device supplier put it, "Don’t believe all the hype and be prepared for sticker shock"—fiber-based equipment can range from two to four times the cost of electronics. Versatile, reliable test equipment will be much in demand to certify and maintain fiberoptic-based systems and improve their cost-effectiveness.

Many manufacturers offer guides to fiberoptics and various fiberoptic instruments. A good, but not exclusive, start can be made with the following:

Designer’s Guide to Fiber Optics, AMP, Harrisburg, PA

Guide to OTDR Measurements, Anritsu Wiltron, Morgan Hill, CA

Premises Fiber-optic Certification and Testing, Siecor, Hickory, NC

Scientific and Laboratory Products, Newport, Irvine, CA

A representative listing of manufacturers of OTDRs begins on p. 172.

Fiber basics dictate testing needs

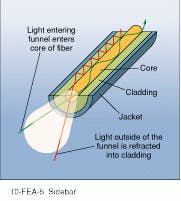

Optical fibers are circular waveguides that conduct optical energy and signals. Although most fibers are made of glass, plastic materials are seeing increased applications over short distances such as in automotive displays. A central core of a fiber has a slightly higher index of refraction than its surrounding cladding layer, which facilitates internal lightwave reflection, permitting propagation down the length of the fiber. A graded-index fiber features decreasing index of refraction outward from its axis, producing the same effect plus an added benefit. This configuration allows light traveling at higher angles to the fiber wall (thereby taking a longer path down the fiber compared to waves running parallel to the core) to travel at higher speeds closer to the wall. All the lightwaves then arrive at the end at roughly the same time, countering spreading or broadening of light pulses.

Fiber geometry and composition determine the sets of electromagnetic fields, or modes, that can be propagated along a fiber. A large-diameter fiber core supports many simultaneous guided modes along it. Radiation modes are those where light rays are aligned at high angles to the core wall and mainly pass into the cladding. Total internal reflection does not take place, and energy is dissipated from the core.

When light is "launched" down a fiber, the modes propagated depend on the input cone angle, within which light rays entering the fiber strike the walls at greater than the critical incident angle for total reflection (see figure). Also important are the light spot size and its centering along the fiber axis. Divergent beams must be collimated and focused before launching into a fiber. These factors are also critical when fibers are coupled in multifiber junctions and splices. Determining the integrity of such fiber-network features is part of the function of fiberoptic test equipment.There are two types of optical fiber, multimode and single-mode. Multimode fiber has multiple paths for all light waves. In single-mode fiber the core diameter is small, comparable to the wavelength, and thus allows only one mode. Single-mode fiber is used for telecommunications due to its high-bandwidth characteristics.

Measures of data-carrying capacity are bandwidth for multimode fiber systems and dispersion for single-mode fiber. Data transmission depends on fiber quality, length, and transmitter characteristics. A key element is dispersion in the fiber that spreads light pulses. Fibers subject to microbends from being pressed against rough surfaces, twisting, and damage from excessive force may have increased back scattering and reflections into the cladding for radiation-mode energy dissipation. Microbends also occur at contact points when one fiber inadvertently crosses others when they are being formed into a cable. For multimode fibers, use of graded-index fibers reduces the significant effect of modal dispersion, increasing bandwidth.

Material dispersion is the slight change in refractive index that occurs with frequency and is more of a factor for less-monochromatic signals such as those from light-emitting diodes (LEDs). Because even a laser light source emits a range of wavelengths, material dispersion will always occur. But at 1300 nm, a minimum dispersion range is found. Here a crossover effect happens--below this wavelength, the shorter "bluer" wavelengths in a source spectrum travel more slowly than the longer "reddish" ones. At wavelengths longer than 1300 nm the situation is reversed.

Absorption by impurities and scattering cause light to be attenuated exponentially as it propagates along a fiber. Rayleigh scattering in fibers is caused by impurities, refractive index fluctuations, and dopants distributed along the fiber. Irregularities in core geometry also cause scattering similar to microbends. A significant cost factor in fiberoptic telecommunications is the number of repeaters needed to maintain signal strength. Repeater spacing is determined by light attenuation along the fiber cables.

Fiberoptic applications usually use infrared wavelengths. The first optical fibers featured LED sources in the 850-nm range. Later systems worked with minimum dispersion sources in the 1300-nm region and in the 1550-nm range where minimum absorption occurs.

Reflections occur in the fiber system at the end of the fiber or where other fiber/air interfaces exist as in a connector, splice, or unintentional break. This interface Fresnel reflection sends a pulse back up the fiber, which can be detected by a test instrument and used to locate breaks and system components. If the fiber end is polished or cleaved at an angle inclined greater than 3.5° off perpendicular to the axis, then no effective Fresnel reflection will be sent back along the fiber.

About the Author

Rick DeMeis

Associate Editor, Technology

Rick DeMeis was Associate Editor, Technology for Laser Focus World from March 1995 through March 1997.