FIBERS FOR HIGH POWERS: Specialty fibers shine as high-power, high-beam-quality fiber sources

WEIHUA GUAN, ZHUO JIANG, AND JOHN R. MARCIANTE

Fiber lasers have many advantages over solid-state and semiconductor lasers, including good thermal management, compact volume, high output power, high beam quality, and low noise floor. While single-mode cores are desirable for eliminating modal dispersion along fiber links, the small cores become obstacles for scaling up the output powers of fiber lasers and amplifiers. Small cores can lead to pronounced nonlinear Brillouin and Raman scattering in fiber lasers because the thresholds for such stimulated processes are inversely proportional to the effective mode areas. Fibers with large cores, however, tend to operate with multiple spatial modes. These characteristics present a significant problem because good beam quality is required for many high-power applications, and much effort has gone into the development of high-beam-quality, high-power fiber sources.

To build high-power fiber lasers, large pump powers need to be coupled into the active media. In a single-mode, diode-pumped fiber laser, the output power is normally less than 1 W because of the availability of single-mode pump power. Pumping the cladding allows use of high-power multimode pumps, and the cladding diameter can be made larger and with a higher numerical aperture (NA) to accept more pump light.1 In such a dual-clad fiber, the shape of the cladding is typically noncircular to promote mode mixing of the pump light and reduce the propagation of azimuthal beams. Such configurations allow for maximum pump absorption efficiency. When dual-clad fibers are used, the output power is primarily limited by optical damage and nonlinear scattering effects.

Coiled and helical-core fibers

To maintain good laser-beam quality with multimode fiber, the fiber is coiled to strip off the high-order modes.2 The core NA is reduced to decrease the number of fiber modes and enhance the discrimination of the coiling process. With such a technique, more than 1.3 kW of power was generated in a fiber laser with near-diffraction-limited beam quality from a 40 µm, 0.05 NA core.3 The fiber was coiled by about 20 cm to strip off the remaining higher-order modes, which did not affect the 650-µm-diameter, 0.48 NA D-shaped inner cladding.

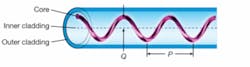

This technique can be integrated into the fiber directly by making a helical-core fiber. The higher-order modes in the core show a larger loss than the fundamental mode, similar to a coiled fiber. This method enables single-mode output using a large multimode core without physically coiling the fiber. In a dual-clad helical-core fiber, P is the helical pitch and Q is the core offset (see Fig. 1).

The differential losses of the modes in the multimode helical-core fiber have been investigated analytically and numerically.4 The results verify coiling predictions and demonstrate that helical-core fibers can be designed to operate under conditions in which a coiled fiber physically cannot. A recent experiment by researchers at the University of Southampton (Southampton, England) demonstrated a single-mode output of 60 W at 1043 nm from a 30-µm-diameter, helical core with a 92 W pump power.5 The ytterbium-doped helical core was offset by 100 µm for an 8.5 mm helical pitch, and had a 0.087 NA. The 0.49 NA inner-cladding diameter was 275 µm. The slope efficiency of the laser was 84%. Even higher output power can be expected with increased launched pump power.

Large-mode-area fibers

When the refractive-index profile is carefully designed, a multimode fiber can work robustly in the single-mode regime. Large-mode-area fibers are typically designed to have a low NA and a large effective mode area. In a 1998 experiment, pulses with energy as much as 0.5 mJ with single-mode beam quality were produced from a Q-switched fiber laser with an inner-core diameter of 21 µm.6 The fiber consisted of a low-NA central-core region and an outer-ring region of raised refractive index.

The low-NA structure, doped with active ions, reduced the number of guided modes for a given core diameter. The outer ring of raised index increased the spot size and the fiber bend loss for the higher-order modes.

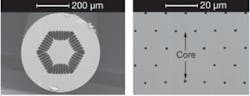

Recently, scientists at OFS Laboratories (Somerset, NJ) demonstrated another type of large-mode-area fiber.7 They demonstrated light propagation in a single, stable, higher-order mode with a core diameter of 86 µm. The fiber incorporated long-period gratings to excite the higher-order mode from the single-mode input. Mode mixing in the fiber was minimized by designing large effective refractive-index differences between modes. The large-effective-area mode was sustainable while bending the fiber down to a 4.5 cm radius.

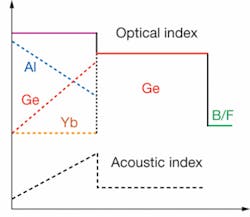

For high-power, narrowband optical sources, suppression of Brillouin scattering is crucial. In one experiment, suppression of stimulated Brillouin scattering was achieved by adding an acoustic guiding layer surrounding the fiber core.8 Adjusting the relative doping level between different doping ions further increased the stimulated Brillouin scattering threshold by 6 dB (see Fig. 2).9 Reducing the overlap integral between the acoustic and optical waves helped increase the threshold.Other fibers

Mode-selective tapers are useful in fundamental mode selection in high-power fiber lasers. In these situations, the fiber-taper structures function as spatial filters. In an experiment in 1999, an output power of 90 W with a beam quality of M2 = 1.4 was generated by using a 2 cm tapered section in a dual-clad fiber-laser cavity.11 It was tapered from the dual-clad ytterbium-doped fiber, which had a clad diameter of 200 µm and core diameter of 15 mm. For the tapered section, the waist diameter was 70 mm and the core diameter was 5.25 µm. Such a single-mode core allows only the fundamental mode to be confined, while higher-order modes radiate away into the cladding. In this experiment, the tapered section increased the laser-beam brightness by a factor of about 3.5 with a power penalty of 20%.

The spatial distribution of the active ions in fibers can be made to provide the maximum gain for the fundamental mode, while keeping the gain for higher-order modes at low levels. In 1999, an experiment demonstrated fundamental-mode selection with a step active-ion doping profile with a radius of 65% of the fiber core when the V number of the fiber was 12.12 Experimentally, the output-beam quality of M2 = 1.2 was measured at an output power of 1.7 W from a fiber with a core diameter of 23 µm. Calculations have shown the scalability of this technique to core diameters as large as 100 µm.13

Many researchers have made significant progress in increasing the output power of fiber lasers with good beam quality, although each method described in this review has its limitations. Consequently, specialty fibers for mitigating higher-order mode propagation continue to be a very active field of research, and the quest for a scalable, robust, single-mode, large-mode-area fiber technology continues.

REFERENCES

1. E. Snitzer, R. Tumminelli, Opt. Lett. 14, 757 (1989).

2. P. Koplow et al., Opt. Lett. 25(7) 442 (2000).

3. Y. Jeong et al., Opt. Express 12(25) 6088 (2004).

4. Z. Jiang, J.R. Marciante, J. Opt. Soc. Am. B 23(10) 2051 (2006).

5. P. Wang et al., Opt. Lett. 31(2) 226 (2006).

6. H.L. Offerhaus et al., Opt. Lett. 23(21) 1683 (1998).

7. S. Ramachandran et al., Opt. Lett. 31(12) 1797 (2006).

8. P. Dragic et al., Proc. Conf. Lasers and Electro-Optics, CThZ3 (2005).

9. M.-J. Li et al., Opt. Express 15(13) 8290 (2007).

10. J. Limpert et al., Opt. Express 11(7) 818 (2003).

11. J. Alvarez-Chavez et al., Proc. Conf. Lasers and Electro-Optics, CWE7 (1999).

12. J.M. Sousa, O.G. Okhotnikov, Appl. Phys. Lett. 74(11) 1528 (1999).

13. J.R. Marciante, presentation at Advanced Solid-State Photonics, Vancouver, Canada (2007).

WEIHUA GUAN and ZHUO JIANG are graduate students, and JOHN R. MARCIANTE is research scientist at the Laboratory for Laser Energetics and associate professor at the Institute of Optics at the University of Rochester, 250 E. River Rd., Rochester, NY 14623; e-mail: [email protected]; www.lle.rochester.edu.