Holey fiber concept spawns optical-fiber renaissance

PHILIP RUSSELL

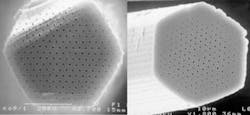

The process developed by University of Bath researchers for making photonic-crystal fiber (PCF) involves stacking rods and tubes of silica glass about 1 mm in diameter into a "preform" with the desired crystalline pattern. This structure is then fused together and drawn down in size in a fiber-pulling tower. It is a tribute to the remarkable properties of silica glass that the photonic crystal structure is preserved even when the linear collapse ratio is three orders of magnitude. The surface-tension forces that made single-material fibers so difficult to make turned out to be stabilized in a holey crystal. At high temperatures, the array of glass-hungry holes, anxious (under the influence of surface-tension) to collapse, fight over a very limited meal of silica.

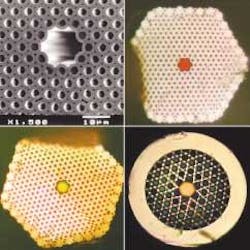

The upshot was, in late 1995, the world's first photonic-crystal fiber (see Fig. 1, left). It had a hexagonal close-packed array of small air channels, free of any gross imperfections or defects. The initial elation of seeing the first really convincing structure was followed by a realization that it was only good for studies of Bragg diffraction; there was no core so there was no waveguide. And the holes were too small to expect a photonic bandgap. So there was no point in introducing a hollow core in the center. Given that it did not seem reasonable to try to make larger holes, an obvious thing to try was a solid core—a filled-in hole. Even this was conceptually problematic. Was it a waveguide or not?On the one hand the average refractive index was lower outside of the core so it looked like a weird sort of step-index fiber. On the other hand there were clear barrier-free pathways of glass along which light could escape from the core. The only option was to try it, something that our team was in the happy position of being able to do (see Fig. 1, right). The rest is history.1 The fiber guided light very well, with one curious feature—it never seemed to support any higher-order guided modes, even at very short wavelengths in the ultraviolet (UV).

Modal sieves

The new waveguiding structure appeared to "sieve away" all but the fundamental mode. The higher-order modes were able to squeeze between air holes—their transverse effective wavelength is shorter and thus they have higher resolving power.2 Seen from another point of view, the cladding refractive index changed strongly with wavelength—a characteristic of photonic crystals—and this caused the core-cladding index step to fall as the wavelength shortened, keeping the number of guided modes constant at 1, regardless of wavelength. In the short wavelength limit, the mode profile actually becomes independent of wavelength, freezing to a shape that fits neatly around the air holes. As a consequence, the numerical aperture of the emerging light is proportional to wavelength—unlike in conventional fibers in which it is approximately constant.

The analysis of this new fiber waveguide has occupied a small army of theoreticians all over the world, so there is now a substantial collection of literature that explains and explores its many features. On the fabrication front, many different solid-core structures have been produced including multicore fibers (very easy to do with the stack-and-draw procedure) and ultrabirefringent (ΔB ~0.01) fibers.3 One attractive feature of PCF made entirely from pure undoped silica glass is that it is intrinsically much more temperature stable than bowtie, elliptical core, or Panda fibers.

Although intriguingly novel and practically useful, solid-core photonic-crystal fibers guide light by a form of total internal reflection. And while they can also guide light by photonic bandgap effects (if the holes are large enough), they were essentially a diversion from our original goal: the realization of a guiding hollow-core fiber in which total internal reflection cannot operate at all (see "The quest for holey fiber began with an intriguing idea").

Meanwhile, theory had shown that photonic bandgaps do exist for silica-air structures when, as in a fiber, most of the propagation is along the axis of invariance. Achieving this experimentally took much more effort. It was necessary to learn how to make photonic-crystal fiber with large air-filling fractions. The first working hollow-core fiber was achieved in 1999 (see photo at top of this page).4

Since then the field has blossomed and the new fibers are finding applications in almost every area of science and technology in which fibers were used before—and even more—and many of the tenets of conventional wisdom that describe what fiberoptics can or cannot do have been irrevocably broken. While we can't mention all the applications, we will highlight a few of the more intriguing and important ones.

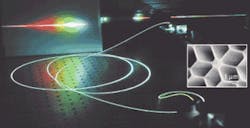

Supercontinuum generation

As the holes in the fiber get larger, the core becomes increasingly isolated until it resembles an isolated strand of silica glass suspended by six thin webs of glass. If the whole structure is also made very small (core diameter ~1 µm), the dispersion of the guided mode becomes radically different from that of conventional fiber. The "cobweb" PCF has a zero dispersion point at l0 = 560 nm, for example (see Fig. 2 inset). As the core gets larger, l0 moves out to longer values, so it is simple to design a PCF with l0 = 800 nm, the region in which Ti:sapphire lasers operate.A team at Lucent (Murray Hill, NJ) discovered that when 100-fs pulses of a few nanoJoules energy are launched into such fibers they display giant spectral broadening, sometimes from 350 to 1650 nm.5 The result is effectively a "sunlight laser" so bright that higher diffracted orders are clearly visible when the light is dispersed at a grating and cast onto a screen (see Fig. 2). The light emerges from a tiny aperture, lasts only a few picoseconds and has the bandwidth of sunlight. In fact, it is brighter than 10,000 suns (>100 GW m-2 sterad-1). Not surprisingly this source is finding multiple applications in frequency metrology, optical coherence tomography, spectroscopy, and low-coherence interferometry.

Particle guidance

Attempts to guide micron-sized particles along hollow fiber capillaries have previously been hampered by the absence of a true-guided mode in the core. The fact is that simple glass capillaries leak badly, losing light at a rate inversely proportional to the third power of the radius. A capillary of bore 10 µm will lose the majority of the light after only 0.5 mm at a wavelength of 800 nm. A hollow core photonic bandgap PCF of course does not (in theory) leak and attenuation values of around 1 dB/m are routine at core diameters of 10 µm.

This means it is relatively easy to trap and guide small particles using the forces that light exerts on dielectric particles—both to trap transversely and accelerate in the direction of motion. Researchers at the University of Bath recently "caught the dancers" in an experiment, reported at CLEO/QELS 2002.6 A vibrating glass plate with a population of particles dancing on its surface was illuminated from below with a laser beam focused into a hollow core PCF. Particles were captured by the laser light and entrained into the hollow core. This technique is being extended to the guidance of atoms and molecules.

Gas-based nonlinear optics

A long-standing challenge in nonlinear optics is the maximization of nonlinear interactions between laser light and low-density media such as gases. Hollow-core PCF is an ideal solution to this unsolved problem, offering high intensities at low power (mode diameter ~10 µm), long interaction lengths (on the order of meters), and good-quality transverse beam profiles.

It is thus set to have a major impact in several fields, including high harmonic generation, Raman-gas cells, ultrahigh-power transmission of laser light, nonlinear optics in gases, laser wake-field acceleration, and cold atom guiding. And if the attenuation losses can be reduced to <1 dB/km, it would be an excellent candidate for long-haul communications, having greatly reduced nonlinearities and lower Rayleigh scattering compared to conventional fiber.

With best recent attenuations on the order of 1 dB/km (solid core) and 1 dB/m (hollow core), PCF is making a major impact in a large number of diverse areas of research and technology. The ability to make a functioning structure from one solid material, thus avoiding the need to find compatible core and cladding glasses, makes it possible to fashion fibers from traditionally "difficult" materials such as polymers7 and chalcogenides. And the list of applications is growing by the month. The "holey fiber" concept has created a renaissance of scientific interest in optical fibers and their applications.

REFERENCES

- J. C. Knight, T.A . Birks, P. St.J. Russell and D. M. Atkin, OFC 1996, postdeadline paper; Opt. Lett. 21, 1547 (1996); Errata, Opt.Lett. 22, 484 (1997).

- T. A. Birks, J. C. Knight, B. J. Mangan and P. St.J. Russell, IEICE Trans. Electron. E84, 585 (2001).

- J. C. Knight, T. A.Birks and P. St.J. Russell, "Holey silica fibres," in Optics of Nanostructured Materials, Editors V. A. Markel and T. F. George, 39 (John Wiley & Sons, New York, 2001).

- R. F. Cregan, et al., Science 285, 1537 (1999).

- J. K. Ranka, R. S. Windeler and A. J. Stentz: Opt. Lett. 25, 25 (2000).

- F. Benabid, J. C. Knight and P. St.J. Russell, Conf. Lasers & Electro-Optics, paper CMJ5 (May 2002).

- M. A. van Eijkelenborg et al., Opt. Express 9, 319 (2001).

Philip Russell is a professor in the department of physics, University of Bath, Claverton Down, Bath BA2 7AY, England; e-mail: [email protected].