Absorber-free process welds transparent thermoplastics

While laser welding of polymers is used in many industrial applications, an infrared (IR) absorber material is typically required to laser-weld transparent thermoplastics (see www.laserfocusworld.com/articles/341585). But that was before researchers at the Fraunhofer-Institut für Lasertechnik (Aachen, Germany) demonstrated that the use of special optics in combination with a proper laser wavelength can produce successful absorber-free weld seams.

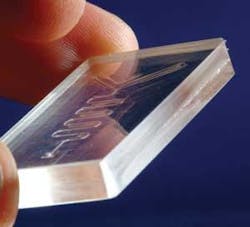

Successful welding without an IR absorber is primarily attributed to the availability of new laser sources at specialized wavelengths (such as ytterbium-doped fiber lasers from 1060 to 1080 nm, erbium-doped fiber lasers from 1530 to 1600 nm, and thulium-doped fiber lasers from 1800 to 2100 nm). Analysis of the absorption spectra of polymer compounds shows particular wavelength values (many of them aligned with the specialized laser source wavelengths) at which sufficient IR absorption occurs to enable welding. And by choosing the proper optics for laser-beam delivery, the numerical aperture of the optic can be chosen to provide enough intensity to melt the boundary layer of a two-part polymer assembly while intensity at the surface of the sample stays below melt threshold. The process is already being applied to high-end medical devices, including this microfluidic mixer that requires transparent materials to allow spectroscopic analysis. Contact Andreas Roesner at [email protected]