Point-by-point UV exposure makes optimum fiber-optic long-period gratings

Optical fibers containing long-period gratings (LPGs) are used (among other things) to sense the refractive index of a surrounding medium, making them valuable for many industrial uses. When the refractive-index change of the surrounding medium to be sensed is plotted against the wavelength of the sensing light, the resulting curve can have a U shape with a minimum value, called the turning point. For optimum sensitivity of the fiber sensor, the period of the LPG should be chosen so that the phase-matching condition is satisfied at its turning point; however, the precision required to do this is so high that achieving this condition is difficult.

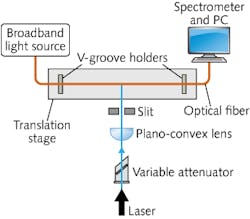

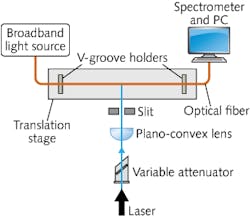

Researchers at Cranfield University (Cranfield, England) have developed a process to reproducibly fabricate LPGs with phase-matching at the turning point. Their approach is based on point-by-point UV exposure, in which a section of photosensitive fiber with a length equal to half the LPG period is exposed to UV light through a slit, which changes the refractive index to create the grating "line." The exposure light is then translated one grating period relative to the fiber to expose the next grating line, and so on until the entire LPG is finished. The translation stage used had a resolution of 7 nm; the slit width could be varied to create a 50:50 or any other duty cycle. The LPG period was on the order of 110 μm. The researchers determined that even changes of less than 100 nm in the period of the LPG can have large effects on the fiber's transmission spectrum when near the phase-matching turning point. Contact Stephen W. James at[email protected].