At the Optical Fiber Communication Conference (OFC '96) later this month in San Jose, CA, engineers from Galileo Electro-Optics (Sturbridge, MA) will demonstrate a module that permits optical amplification of 1.3-µm signals. Development of practical fiberoptic amplifiers operating at 1.3 µm is of interest because that is the wavelength of minimum dispersion for silica optical fiber; also, the majority of the installed terrestrial fiberoptic networks operate in this region. Fluoride fiber doped with praseodymium has successfully been used for 1.3-µm amplification, but the material is challenging to work with. Over the past several years, Galileo has addressed the development of this gain medium.

Fluoride fiber is inherently weaker and less chemically stable than silica fiber. Many concerns center on the hygroscopic properties of the material, but improvements in the fiber manufacturing process have resulted in a durable, coated, low-loss single-mode fiber that can survive hundreds of hours in water. Galileo engineers also needed to perfect a reproducible and manufacturable process for drawing the Pr-doped fiber.

Packaging the gain medium presented another set of challenges. According to Todd Truax at Galileo, telecommunications equipment manufacturers wanted a package that could be dropped into existing systems, without unusual engineering requirements. For this to be possible, the fluoride fiber had to be coupled to conventional telecommunications silica fiber, which was difficult because the materials are so dissimilar. The core diameter of silica fibers (about 5 µm) is much larger than that of fluoride fibers (1.7 µm), while the numerical aperture of silica is 0.14 compared to 0.39 for fluoride.

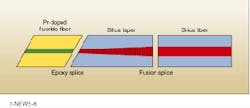

To overcome these incompatibilities, Galileo engineers devised an angled thermally expanded core (TEC) fusion splice (see figure). This mechanical fiber splice permits joining of the small-diameter Pr-doped fiber to conventional larger-diameter telecommunications fiber. In the tapered region, the TEC is created with a carefully controlled heating process that results in an increase in the effective core diameter. Precise control ensures a linear taper. During the tapering process, dopant ions in the silica migrate to different regions thereby altering the refractive index and modifying the numerical aperture.

To minimize back reflections, the TEC taper is spliced to the Pr-doped gain medium through an angled epoxy splice. Truax reports that this configuration results in a splice loss of less than 0.5 dB in the module, compared to 4 dB that the dissimilar materials alone present. The Pr-doped fiber amplifier module package fits in the palm of a hand. Truax indicates several manufacturers are evaluating the package.

For example, Atx Telecom Systems (Naperville, IL) is incorporating the module in its high-power optical amplifiers and hopes to realize amplified power outputs of 16–22 dBm. Donald Sipes, vice president of technology, says that its 1-µm diode-pumped Nd:YLF laser can pump the 1.3-µm amplifier, and life-tests and performance tests are currently underway at Atx. The Pr-doped module eliminates constraints of solid-state electro-optical regenerators and offers telecommunications providers an avenue to retain the existing 1.3-µm fiber background.

About the Author

Heather W. Messenger

Executive Editor

Heather W. Messenger (1955-1998) was Executive Editor for Laser Focus World.