Direct endface bonding creates all-optical-fiber photodetector

Although bulk photodetectors are readily available, integration with optical fibers remains a challenge. But by bonding 2D molybdenum disulfide (MoS2) directly to the endface of an optical fiber, researchers at Nanjing University (Nanjing, China) have designed an all-optical-fiber integrated photodetector without air gaps or other free-space optical interfaces that operates over visible wavelengths with high responsivity.

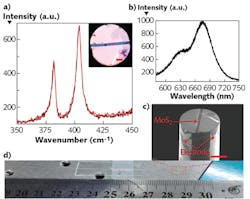

Fabrication of the all-fiber photodetector begins with depositing gold on a cleaved end face of a single-mode SMF-28 optical fiber. The lateral walls of the fiber are then polished and the endface is scratched across the middle, creating two separated electrodes. Next, the MoS2 film on a mica substrate (prepared by chemical vapor deposition) is transferred to deionized water and then bonded to the fiber endface in a dip-coating process that produces a wide strip of the 2D material over the fiber core. Photoluminescence characterization of the photodetector surface shows two peaks at 626 and 677 nm corresponding to MoS2 excitons. For a 400 nm light source with 4.4 nW input, photodetector responsivity as high as 0.6 A/W was observed for a 4 V bias and 0.01 A/W for no bias. The all-fiber photodetector provides a new strategy for integration of 2D materials in fibers for optoelectronic and sensing applications, and could be extended to infrared wavelengths by bonding graphene or black phosphorus to the endface. Reference: J.-H. Chen et al., Nanoscale (Dec. 28, 2016); doi:10.1039/C6NR08436B.

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.