Specialty Fiber: Multiple applications benefit from advances in high-performance Er:Yb co-doped double-clad fiber

Within the past two decades, double-clad active optical fibers have advanced to a preeminent position, currently being considered among the most efficient, robust, compact, and cost-effective light sources available on the market. Double-clad fibers offer large volumes for optical pumping and rare-earth ion-doped cores such as ytterbium (Yb3+), erbium (Er3+), thulium (Tm3+), and holmium (Ho3+), to cite the most common.

Typically, semiconductor-based optical sources are used to pump rare-earth ions within their respective absorption bands to either amplify optical signals or generate laser radiation at one of their emission bands. Therefore, the availability of pump sources in combination with the absorption and emission bands of rare-earth ions is the main driver for amplifier and laser designs, and also dictates the limits of obtainable optical performance.

The specific example of Er-doped fibers—widely used for their emission around 1.55 μm, the third telecommunication window—illustrates this fact: the Er3+ ion has several absorption bands, with 980 and 1480 nm being the preferred ones based on the favorable absorption cross-section. However, 980 nm diodes are power- and stability-limited, while the limited inversion of Er3+ ions at 1480 nm drastically increases the noise of the signal, inhibiting the amplifier performance.

To overcome these limitations and to offer high-efficiency and high-power 1.55 μm light sources, co-doping erbium with a sensitizer ion such as Yb was proposed by Grubb et al. in 1991.1 Since then, Er:Yb co-doped fiber-based amplifiers and laser systems have been successfully developed, and are available on the market for diverse applications.

About Er:Yb co-doped double-clad fiber

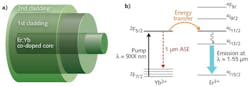

The typical architecture of double-clad fibers (see Fig. 1a) comprises a center core surrounded by first and second cladding layers made with lower refractive indices and form the double-clad structure. The center core is designed to guide single-mode or multimode emission around 1.55 μm, and contains Er and Yb dopants in this case. The first cladding is used as a pump guide, and is usually shaped to maximize the pump-core overlap for efficient absorption.

The energy diagram of Er:Yb co-doped media and the sensitizing role of the Yb3+ ions are illustrated in Fig. 1b. Benefiting from availability of highly efficient and highly reliable diodes at 915, 940, and 976 nm, population inversion occurs within the energy bands of the Yb3+ ions and is followed by a favorable energy transfer to one of Er-excited states, resulting in stimulated emission around the 1.55 μm wavelength. The sensitizer effect is optimized when the rate of energy transfer and the lifetime of the Er-excited state are shorter than the lifetime of the Yb-excited state. When this condition is not satisfied, the Yb-excited state will spontaneously decay first, resulting in parasitic amplified spontaneous emission (ASE) in the 1 μm wavelength range.

In non-optimized Er:Yb fibers, the parasitic 1 μm ASE competes with the desired 1.55 μm laser emission, leading to dramatic consequences above certain pumping levels. Co-doping the silica glass matrix of the core with phosphorus favors the rate of energy transfer, mitigates the parasitic 1 μm ASE, and enables highly efficient 1.55 μm emission in a compatible fashion with other standard optical fibers.

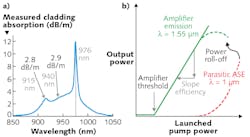

Another advantage of phosphorus-doped silica glass can be seen on the measured absorption spectrum of an Er:Yb fiber (see Fig. 2a). The addition of phosphorus flattens the absorption at 915 nm and even more at 940 and 960 nm. As a result, non-wavelength-stabilized 915, 940, and 960 nm pump diodes can be used since the spectral shift does not have negative effects on the fiber amplifier performances and offers higher stability. In addition, the price per watt for 915 and 940 nm pump diodes is significantly less expensive than 976 nm, which would require wavelength stabilization because of the sharpness of the absorption peak at this wavelength.

The typical output performance of an Er:Yb co-doped fiber amplifier is depicted in Fig. 2b, showing a linear increase in output power with launched pump power. The 1.55 μm emission is characterized by the lasing threshold and a slope efficiency. Pulsed systems include additional temporal characteristics. When using non-optimized Er:Yb fibers, the parasitic 1 μm ASE builds up and competes with the 1.55 μm amplified signal above a certain pumping level affecting efficiency stability and exposing the system to irreversible damages. Therefore, the core composition of Er:Yb co-doped fibers must be balanced and carefully tailored to fulfill application-specific requirements.

High-resolution home entertainment

Cable TV providers supplying entertainment directly to the home are currently using Community Antenna TV (CATV) amplifiers to develop high-flexibility networks. These platforms are enabled by use of optical amplifiers and constantly evolving based on the user demand. Fiber-based amplifiers are preferred over semiconductor-based devices since they do not require optical-to-electrical energy conversion.

Both Er-doped fiber amplifiers (EDFAs) and Er:Yb-doped fiber amplifiers (EYDFAs) are available on the market. These modules amplify and split the input signal into multi-output channels. EDFA and EYDFA are required to deliver high continuous-wave (CW) output power, low noise, and highly reliable performances in a cost-effective fashion. One module is typically made of a single 10 W pump diode at 915 or 940 nm, pumping a few meters of Er:Yb DC fiber to deliver watt-level 1.55 μm signals.

EDFAs are typically core-pumped amplifiers able to deliver up to 500 mW (or 27 dBm) of output power. On the other hand, cladding-pumped EYDFAs offer power scaling capabilities up to a few watts. Because of the single pump diode design requirement, optimized Er:Yb fibers must combine lowest threshold and highest efficiency to extract the highest gain possible. In addition, the parasitic 1 μm ASE must be efficiently mitigated to ensure stability and low noise.

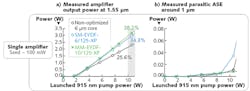

The data in Fig. 3 illustrate the impact of the Er:Yb fiber (EYDF) composition and design on the amplifier performance for the 1.55 μm emission (a) and the parasitic 1 μm ASE (b). The slope efficiency can be increased by more than 40% (from 25.6% up to 35%) when using an optimized EYDF design. For example, up to 2.7 W (34 dBm) of single-mode 1.55 μm emission can be achieved with the SM-EYDF-6/125-XP (Nufern) in a single amplifier. The parasitic 1 μm ASE is efficiently mitigated below at 30 mW at the maximum pump power of 10 W.

Further power scaling of EYDFAs is possible by using larger core sizes. A demonstration with a 10-μm-core optimized MM-EYDF-10/125-XP (Nufern) shows low threshold and 38% slope efficiency delivering more than 3 W of 1.55 μm light for almost no parasitic ASE (see Fig. 3). Further power scaling is possible at the cost of the amplifier threshold, which is an important consideration for pump-power-limited applications.

Lidar and medical applications

Light detection and ranging (lidar) applications use CW or pulsed laser light to probe targets at a distance in a diversity of configurations and deployment conditions. Systems suitable for lidar must emit laser light around 1.5 or 2 μm to provide good atmospheric transmission and eye-safe operation. Compactness, simplicity, and cost-effectiveness are additional requirements for lidar application that are common to several medical applications as well.

These systems generally combine one- or multiple-stage amplifiers, and are not limited by available pump-power. Tailored EYDF fiber-based amplifiers must be designed to deliver tens of watts of output power while strongly mitigating parasitic phenomena, including 1 μm ASE and nonlinear effects such as stimulated Brillouin scattering (SBS). Therefore, fiber designs with core diameter of 10 μm or larger are often used in combination with optimized composition.

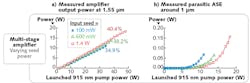

The performances of one of our most recent double-clad active fibers, the MM-EYDF-10/125-XPH, are summarized in Fig. 4. In a single-stage design with 100 mW of input seed power, 35% efficiency is achievable with up to 10 W output power. Beyond this level, the onset of parasitic ASE compromises the amplifier performances. It is often preferable to use a two- (or multi-) stage amplifier design or a master oscillator power amplifier (MOPA) architecture to further scale the output performances.

A two-stage amplifier design can be used. The first stage, made with a high-efficiency and low-threshold EYDF (such as the SM-EYDF-6/125-XP [Nufern], for example), can be used to seed the second stage made with a few meters of MM-EYDF-10/125-XPH. This EYDF, optimized for high efficiency and low ASE, is pumped by six combined 10 W pumps. A pump-limited measurement was recorded with 40% efficiency and 18 W of output power. The measurements show that the efficiency and onset of 1 μm ASE increases for higher input seed power, which must be considered for further power scaling.

Recent results with a cascaded MOPA design (using MM-EYDF-12/130-HE) report a pump limited output of 56.4 W at 1.55 μm and slope efficiency around 40%. This single-frequency design was able to reach a linewidth of 83.5 kHz at the maximum output power.2

Large-mode area for power scaling

Ongoing research focuses on pushing the performance of EYDF even further. Several research groups are developing fiber-based amplifiers and lasers systems delivery in a few-hundred watts of output power, paving the way towards the kilowatt level. Optimization of the active fiber is critical at these power levels—not only must the composition be optimized, but the core diameter must be increased to offer high doping levels and mitigate nonlinear effects while offering high beam quality.

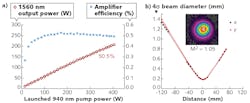

Large-mode area (LMA) Er:Yb fiber designs are developed to limit the number of transverse modes as the fiber's core size increases. Typically, a pedestal layer is added surrounding the core to effectively lower the NA and offer stable single-mode operation. Various geometries of LMA-EYDF are commercially available. Recently, researchers from BAE Systems (Nashua, NH) reported the highest efficiency achieved with a single-frequency Er:Yb fiber amplifier at 1.55 μm using a 25-μm-core and 300-μm-clad-diameter fiber (Nufern LMA-EYDF-25P/300-HE).3

Results of this research (see Fig. 5) show the measured output power and the beam quality, respectively. Using 940 nm pump diodes, the researchers achieved up to 50.5% slope efficiency and were able to reach up to 207 W of average power in the single-frequency regime. In addition, the m2 measurement of 1.05 indicates a very high quasi-diffraction-limited beam quality, which is among the highest values reported to date with LMA pedestal fiber designs. These results, published in 2015, illustrate the high potential of Er:Yb co-doped double-clad fibers for future power scaling application needs.

REFERENCES

1. S. G. Grubb, D. W. Anthon, W. L. Barnes, and J. E. Townsend, "Sensitized erbium fiber optical amplifier and source," U.S. patent 5,225,925 (1993).

2. X. Bai et al., IEEE Photon. J., 7, 6, 7103106 (2016).

3. D. Creeden, H. Pretorius, J. Limongelli, and S. D. Setzler, "Single frequency 1560nm Er:Yb fiber amplifier with 207 W output power and 50.5% slope efficiency," Proc. SPIE, 9728, 97282L (2016).

About the Author

Clémence Jollivet

Clémence Jollivet is a scientist at Nufern.

Kevin Farley

Kevin Farley is a scientist at Nufern.

Adrian Carter

Adrian Carter is chief technology officer at Nufern.

Dr. Kanishka Tankala

Vice President Specialty Fiber Business

Dr. Tankala is Vice President of Fiber business at Nufern. Prior to joining Nufern he was Technical Manager at Lucent Specialty Fiber and a scientist with SpecTran Specialty Optics. Dr. Tankala also worked as a Research Associate at the Norton Company. He received his M.S. and Ph.D. from Pennsylvania State University in Metals Science and Engineering. He received his B.E. in Metallurgy from the Indian Institute of Science and B. Sc. in Physics from Delhi University. He is a Member of Connecticut Academy of Science and Engineering, Member of Sensor and Instrumentation Technical Advisory Committee to the Department of Commerce and a Senior Member of SPIE.