FIBER LASERS: Fiber sources reach multimegawatt peak power in ns pulses

FABIO DI TEODORO AND CHRISTOPHER D. BROOKS

Rare-earth-doped fiber lasers and amplifiers have emerged as practical and compact optical sources in many areas of interest. An example is the generation of multikilowatt continuous-wave (CW) power with good beam quality for laser welding and cutting.1 Under pulsed operation, fiber-based emitters are attractive as sources of highly repetitive (multikilohertz pulse repetition frequency) pulses with durations of a nanosecond or shorter with high pulse energy, peak power, and average power. Fiber-based emitters offer a number of attractive features over traditional solid-state lasers. Their distributed thermal load, resulting from large surface/active-volume ratios, favors painless waste-heat removal from the gain medium. Moreover, the emitted beam quality is independent of power and resistant to thermomechanical disturbances, thanks to single-transverse-mode waveguiding. These benefits, combined with high optical efficiency (better than 60% to 70% in ytterbium [Yb]-doped fibers), compact and modular form factor, and support for alignment-free and monolithic packaging, make pulsed-fiber sources destined for widespread use in military, scientific, medical, and industrial applications.

Effects of high peak power

The generation of high peak powers in fibers has been limited by the onset of optical nonlinearities, which can cause spectral degradation, power fluctuations, and feedback effects. Another problem has been the build up of amplified spontaneous emission (ASE) between pulses, which is a consequence of the high gain available in the fiber core and continuous pumping. Excess ASE reduces the fiber’s energy-storage capacity and ultimately leads to parasitic lasing.

A straightforward way to avoid optical nonlinearities is to enlarge the fiber core (in comparison to fibers used for telecommunications) to relieve the in-core peak intensity, while reducing the fiber length. Large-core, intrinsically single-mode fibers are difficult to fabricate because they require a very small refractive-index difference between the core and the cladding, which restricts the diameter of single-mode cores in ordinary Yb-doped fibers to about 15 µm. Off-the-shelf large-core fibers tend to guide multiple transverse modes, which degrades the beam quality. Good beam quality can be recovered by coiling multimode doped fibers at an appropriate radius to suppress high-order modes via bend loss.

Using this method, peak powers of about 1 MW in Yb-doped fibers with near-diffraction-limited beam quality have been obtained.2, 3 In practice, the mode field in coiled, large-core fibers does not fill the core but is actually compressed against the outer edge of the bend, which can offset the benefit of a large core area.4 Other groups have explored fiber designs that depart from the traditional step-index profile and support a “flat” fundamental mode of greater area (hence lower peak intensity and lower nonlinearity) compared to ordinary fibers.5, 6

Very large cores for megawatt peak powers

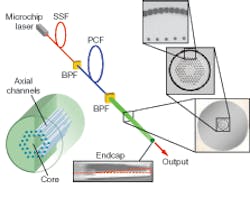

Our approach has been to use photonic-crystal fibers (PCFs). In these fibers, an array of hollow axial channels surrounds the solid, doped core (see Fig. 1). The geometric characteristics of this array (finely controllable upon fabrication) shape the waveguiding properties of the PCF with high resolution, precision, and reproducibility. As a result, intrinsically single-mode cores of much larger size compared to standard fibers can be readily obtained without incurring waveguide loss caused by imperfections.

To take full advantage of the PCF properties, we operate these in a master-oscillator/power-amplifier (MOPA) architecture. The MOPA design affords optimization of energy storage and effective ASE containment through gain staging and interstage spectral filtering. Moreover, the MOPA architecture is inherently modular and, therefore, amenable to a flexible form factor that favors packaging and rapid integration and deployment in existing platforms.

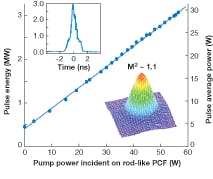

We created several configurations (see table). In its simplest realization, our gain-staged MOPA featured an Yb-doped solid-silica fiber preamplifier followed by a 40-µm-core, single-mode, Yb-doped PCF.7 This source generated 1 ns pulses of 1 mJ energy, 1 MW peak power, and 10 W average power (pulse repetition frequency of about 10 kHz) in a spectrally narrow (approximately 10 GHz linewidth) and diffraction-limited (M2 of 1.05) output beam of very high spectral purity (greater than 45 dB pulse-to-background ratio). This combined set of performance parameters represented a substantial step up compared to the traditional expectations for fiber lasers/amplifiers.

| Core diameter (µm) | Beam quality (M2) | Pulse energy (mJ) | Peak power (MW) | Average power (W) | Spectral linewidth (GHz) | Signal-to-noise ratio (dB) |

|---|---|---|---|---|---|---|

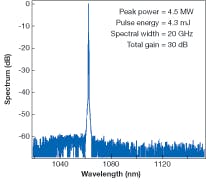

| 100 | 1.3 | 4.3 | 4.5 | 42 | 20 | >50 |

| 70 | 1.1 | 3.1 | 3.0 | 30 | 20 | >50 |

| 40 | 1.0 | 1.05 | 1.1 | 10 | 10 | >45 |

| 41 | 1.2* | 0.8* | 0.8* | 7.5* | 10* | >45* |

| *Linearly polarized output | ||||||

In another embodiment, the large-core PCF used was equipped with birefringence-inducing stress elements, which yielded a robust single-polarization output. In this case, we demonstrated peak power in excess of 800 kW in a 100:1 linearly polarized beam of excellent beam quality (M2 of 1.2) and still high spectral purity. Through direct harmonic generation of the PCF output in nonlinear crystals, we also obtained peak powers of 400 and 200 kW at visible (green) and UV wavelengths, respectively. These values represent the highest peak powers in a linearly polarized output directly from a fiber and in fiber-generated harmonics to date.

Further power scaling in PCFs is achievable with even larger doped cores. To maintain single-mode operation, the fiber core/cladding index step must be lowered to the extent that, ultimately, effective optical confinement cannot be retained in the presence of fiber bends. A simple solution to this problem is to avoid bending altogether as provided by the rodlike PCF concept. Rather than a thin and flexible polymer jacket, a rodlike PCF features a rigid glass shell (greater than 1 mm diameter) designed to retain a straight shape, thus avoiding bend loss.

Researchers at the University of Jena (Jena, Germany) have shown that this configuration supports high thermal loads in CW operation.8 It is in the generation of high-power, short repetitive pulses, however, that a rodlike PCF becomes the quintessential “missing link” between ordinary fibers and bulk crystals. The oversized doped core (we have demonstrated up to 100 µm diameter) ensures ample energy storage and efficient pump absorption even in short, practical lengths (for example, about 50 cm or less). At the same time, these lengths are sufficient to handle large heat loads and support multikilohertz pulse-repetition frequencies and high-average-power operation. Finally, being a single-mode waveguide, a rodlike PCF will generate a near-perfect beam quality.A promising outlook

The demonstrated possibility of obtaining multimegawatt peak power, multimillijoule pulse energy, near-perfect beam quality, and high spectral quality in a fiber-based source is a new and significant result in the solid-state-laser arena. In fact, the combination of MOPA architecture and very large-core PCF bridges the ultimate performance gaps between bulk and fiber source performance. As a result, many applications requiring performance that is traditionally off-limits to fiber-based sources can now benefit from their well-known qualities of modularity, efficiency, and simplicity. Examples include very high-peak-power visible and UV standoff transmitters for remote sensing, air- and spaceborne ladar imagers with ranges of hundreds of kilometers, multimillijoule ultrashort-pulse lasers for materials processing and spectroscopy, high-speed percussion drilling of hard materials, and many others.

References

1. V. Gapontsev, Photonics West-Lase 2006 (San Jose, CA, 23-26 January 2006), Paper 6102.

2. A. Galvanauskas, IEEE J. Select. Topics Quantum Electron. 7, 504 (2001).

3. R.L. Farrow et al., Proc. SPIE 6102, 61020L (2006).

4. J.M. Fini, Optics Express 14, 69 (2006).

5. J.W. Dawson et al., Proc. SPIE 5335, 132 (2004).

6. W. Torruellas et al., Proc. SPIE 6102, 61020N (2006).

7. C.D. Brooks and F. Di Teodoro, Optics Express 13, 8999 (2005).

8. J. Limpert et al., Optics Express 14, 2715 (2006).

9. C.D. Brooks and F. Di Teodoro, Appl. Phys. Lett. 89, 111119 (2006).

Fabio Di Teodoro is a senior scientist and Christopher D. Brooks is a development engineer at Aculight, 11805 North Creek Parkway South, Bothell, WA 98011; e-mail: [email protected]; www.aculight.com.