From his roots in electronic engineering to his passion for business, Michael Lebby, CEO of Lightwave Logic, is well known as an overachiever. The fact he holds two doctorates, a Ph.D. and a higher doctorate in engineering (D.Eng), earned him a nickname among his children, who jokingly refer to him as “Dr. Dr. Lebby.” Coupled with his initial bachelor’s degree in optoelectronics and an MBA from the University of Bradford in the U.K., Lebby has a background ideally suited for a CEO in today’s pulsing photonics landscape.

Early career

While pursuing his degrees, Lebby launched what became a luminous career at the British version of Bell Labs, the Royal Signal and Radar Establishment (RSRE), where he focused on material and characterization issues of gallium arsenide (GaAs) and indium phosphide (InP) devices. From there, he became a researcher at AT&T Bell Labs, where he explored optical and electrical gain for optical switching in one device. This was novel research in 1985, when the community was focused on the concept of optical computing and it offered experience to bolster a young career. Unbeknownst to Lebby back then, his work was foundational for photonic integrated circuits because he and other researchers at Bell Labs focused on ways to interconnect different photonic devices.

The Motorola effect

While the work at Bell Labs was interesting, Lebby is the first to point out that his attention was drawn to the pursuit of vertical-cavity surface-emitting laser (VCSEL)-based product solutions. He had the opportunity to move to Motorola and explore this topic in a more focused manner, and had the first devices raised in two or three months. During the next few years, Lebby and his Motorola colleagues designed VCSEL-based interconnect technology (single and multichannel) that are the de facto standards in today’s environment. While Lebby and his colleagues considered VCSELs to be ideal for optical interconnects and also optical data storage, they never predicted the use of VCSELs in laser mice or structured light sensors that can be found in mobile phones today with volumes of many hundreds of millions, if not billions of units.

Optical data storage also became a strong research emphasis. At the time, data storage was implemented using 780 nm edge-emitting laser diodes, as used in CD-ROMs. If you used a VCSEL, you didn’t have the elliptical beam—you had a circular beam. That VCSEL device could be used more efficiently to get a diffraction-limited spot, which created huge opportunities in the optical storage market. In the mid-to-late 1990s, those applications were not as successful for the VCSEL market compared to parallel optical interconnects at the time (1990s), but it was an area of real research interest by both device manufacturers as well as optical data storage companies.

Telecom bubble impacts

Lebby moved on from Motorola after nine years and focused on the fiber-optic datacom and telecom business, working at Tyco Electronics. Not long thereafter, he transitioned to Intel Capital, where he focused on how to best use silicon for photonic applications. On the business side, he worked on optical investments at both the device as well as the system networking level.

And then the telecom bubble hit (~1998-2001). Generated by a frenzied buying mentality, the sheer volume of optical components purchasing had to end. Ultimately, the buying dried up, and it left a lot of companies struggling.

Lebby recalls having dinner with Kevin Kalkhoven, who as CEO of JDS Uniphase at the time, predicted in 2000 that the industry would be in the doldrums until at least 2010—which was not only accurate, but incredibly astute. What was so interesting was the timing of the prediction: at the height of the bubble. As we all know today, the rippling effects of the bubble continued into the next decade, beyond 2010. The lesson learned from this dinner was that we can’t all be visionaries like the French philosopher Nostradamus, or Kalkhoven, but as an industry we do need to do more work on technology roadmaps, especially in photonics.

Developing a trade association

During those difficult years, Lebby transitioned into an association executive at the Optoelectronics Industry Development Association (OIDA). He worked to predict where technologies were headed, creating workshops, market reports, and technology roadmaps that both fueled and recounted progress in key areas. With an industry reeling in the aftermath of the telecom bubble, assembling leaders in the field to identify a path forward generated a newfound excitement. This enthusiasm, in turn, spurred future growth through the exploration of the intersection of industry, government, and technology. It created a way for the photonics industry to speak with one voice.

And the organization tackled emerging applications ahead of their time—for example, green photonics. Lebby recalls raising the concept, to the bewilderment of colleagues who questioned what it meant and why it was needed. His focus remained resolute, with an eye toward future impacts. In our recent discussion, Lebby recounted that as a community of engineers, OIDA members focused on designs to make things more efficient; it’s in their natural ability to strive for power consumption that’s more efficient. At its roots, this is green photonics, figuring out ways to be more efficient. This movement proved to be prolific, as today leaders in the field explore how to get power consumption down in data centers and communications equipment in general.

In addition to pushing the envelope on topical exploration, OIDA was well known for its market data, driven by reports Lebby oversaw and produced based on workshops. The association assembled CTO-level leaders to discuss forward-looking issues, and from that dialogue produced a roadmap to move the industry toward a future state. These roadmaps identified the obstacles and opportunities ahead.

Moving back into technology development

Lebby’s next move surprised many when he went from OIDA to GM and CTO at Translucent Photonics, based in the heart of Silicon Valley. Why does someone who ran a trade association go back into technology and a different discipline? The same driving force that sparked Lebby’s moves throughout his career played a factor here: Novel and interesting work.

Translucent was exploring something no one had really done before commercially: 1) developing and productizing germanium-tin (GeSn) template wafers onto large-format silicon wafers (Ge-on-Si) to enable cost-effective and ultrahigh-efficiency concentrated photovoltaics (CPV) multijunction solar cells for the CPV industry, and 2) epitaxially growing GaN/InGaN onto silicon wafers as opposed to sapphire for both LEDs and power field-effect transistors (FETs). The work fueled Lebby’s entrepreneurial side, allowing him to build up a division to address these topics, as well as innovating within the company to support new opportunities.

The world of PICs

Lebby continued to have an impact on the industry from a technology advancement perspective and, in 2013, accepted a position as the CEO of Onechip Photonics, where R&D focused on communications-based InP photonic integrated circuit (PIC) and optoelectronic integrated circuit (OEIC) platforms. While the company ultimately faltered from funding issues, their successfully developed high-performance PIC technology platform lived on, sparking several startups and advancing industry dialogue on these platforms. At a time when there was a lot of uncertainty around what would become of InP, this work sparked new ideas and opportunities for many in the global photonics community.

Connecting with Lightwave Logic

In June 2015, Lebby joined the board of Lightwave Logic, which focuses on polymers, and shifted his trajectory. Lebby was interested in exploring a new way of tackling engineering issues, starting from the foundation of strong electro-optic polymers and identifying the vehicles to achieve commercial success. By 2017, Lebby had taken the helm and become the organization’s CEO leading the company in its design of very high-speed, low-power optical modulators for fiber-optic communications.

In parallel during this timeframe, Lebby became a technical expert to the European Commission, and had a role in imagining what may be needed for the industry’s future. The corresponding roadmap exercise that came to fruition helped plot out which technologies have merit and the parameters needed in electro-optic material for a polymer modulator to be better than previous polymer designs as well as incumbent semiconductor technologies such as silicon, indium phosphide, and lithium niobate. It’s when he realized that the goalposts had changed compared to previous telecom modulator designs that required 20-year lifetimes, super-high reliability, and extreme-temperature ranges. With cooling systems for data centers now common-place, electro-optic polymers now offer a viable solution in this environment. The concept of cleaner optics, using faster optical modulators and lower power, brings with it a lot of opportunity and fits in well with his original ideas and promotion of green photonics back at OIDA.

The downside is that electronic and optical chips can consume lots of power. So the challenge is: How does an engineer design green in a way that can impact optical networks efficiently? Do they make electronic chips small and efficient with lower power consumption? Or do they make the optics cleaner and faster? Lebby believes the answer lies in doing both, which is what drove him to be a participant in the roadmapping process in the first place.

A chemistry company

Today, as CEO of Lightwave Logic, Lebby has his hand in the company’s technical direction, and they are working on an electro-optic organic polymer technology for fiber optics, a deviation from traditional semiconductor solutions.

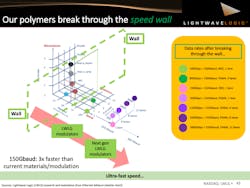

Lebby has big visions for the company and its products, hoping to displace the incumbent semiconductor platforms such as silicon, indium phosphide, and lithium niobate. He believes the superior performance and applicability of organic polymer technologies will become the optimal choice for fiber-optic needs within the next 5–10 years. Even today, the performance of polymers are 2–3X faster in bandwidth than standard devices and are in the lower power range. Depending on the architecture, these bandwidths can be an order of magnitude lower and, given recent results with Lightwave’s partners’ optical network systems channel speeds, have the potential to be not only 200 Gbit/s per channel, but 400 Gbit/s or even 800 Gbit/s per channel sometime in the future.

When it comes to commercialization of the technology, Lebby points to three criteria that will help Lightwave Logic achieve success: what they are doing, how they are doing it, and why they are doing it. Coming back to the roots of business objectives, tactics and strategy will keep the work on track, and Lebby sees this work playing out effectively. Currently, the company is creating modulators (what), working with different partners to scale solutions (how), and working to make electro-optic polymers as ubiquitous as organic LEDs as seen in most mobile phone and displays for TVs and monitors today (why). This approach leads to a creative business model that’s not purely making components and selling them. There are companies who want to use their technology and strong intellectual property/patent position effectively. This means Lightwave Logic will be licensing the polymers, individualized to align with different manufacturing plans. In short, it means looking at unique ways to achieve scale with a proprietary technology that has the potential to enable customers’ businesses in many ways.

Bright future

Looking ahead, Lebby envisions a profitable company leveraging this combined creation/licensing model. Licensing is a fairly new approach in the fiber optics space, but it’s been tested and proved by companies in the display market, especially those focusing on OLEDs. Lebby feels that a combination of licensing and product business model will meet current fiber industry demands.

Career reflection

Looking back on Lebby’s career during the past 40 years, he’s very much been an innovator and inventor (more than 230 patents issued) with a passion for design. Whether it’s designing epi-materials or devices, or transceiver modules, he enjoys taking a lead role in the design part of the process. This design enthusiasm transcends industries: He has dabbled in fashion design, working on sketches of new clothing with his mother, and designing avant-garde eyeglasses, which he wears daily with his well-recognized black dress code. Clearly, design is core to who he is as a professional.

Lebby’s also held adjunct professor roles and has worked in academia throughout his career, precisely because he likes to consider the ways academia and industry can leverage one another to create a better product and experience. For example, he remembers when he was doing VCSEL work, he gave a presentation at a conference and realized universities could benefit from the use of the technology, so he made sure the mountain of VCSELs his team created made their way into those research efforts. This collaboration yielded additional R&D insights for the company, helping them gain knowledge about what was needed in the space. Lebby’s experience is proof that when done well, industry/academic collaboration can support the industrial position.

Advice for the next generation

With such a prestigious career as a backdrop, Lebby is a resource with a wealth of knowledge for up-and-coming scientists and engineers. During our recent conversation, he said he has the same advice to offer an entrepreneurial photonics engineer at a startup or an intrapreneur driving new projects and divisions within a corporate organization: Look to the future. He emphasizes trying to figure out what’s going to be the next technology surge, and thinking about the technology cycle and how long the current state of the art will last. How will today’s solutions evolve? At some point, existing technologies get displaced, so visionaries work to identify the solutions that will make today’s technologies obsolete to enable new and exciting products. Lebby calls this the ‘Law of Incumbency’—a technology that gets used until it either runs out of steam or is replaced with something more competitive.

Because, as Lebby’s career points out, the future for the photonics industry can’t always be predicted, but it can be shaped.

About the Author

Jose Pozo

Chief Technology Officer, Optica

Jose Pozo joined Optica in March 2022, and has spent more than 25 years working in photonics. He earned a PhD in quantum physics from the University of Bristol (U.K.), and an M.Sc. and B.Eng. in telecom engineering from UPNA, Spain / VUB (Belgium). Prior to joining the European Photonics Industry Consortium (EPIC) in 2015 as CTO, Jose was a Senior Photonics Technology Consultant with PNO Consultants, with some of the main accounts such as CERN, Thales, and TE Connectivity. He has worked at TNO, The Netherlands Organization for Applied Scientific Research, and as a postdoctoral researcher at the Eindhoven University of Technology in the Netherlands, where he contributed to the early development of EFFECT Photonics.