Nanoparticle-embedded stretchy optical fibers monitor body temperature

Human body temperature is one of the most significant physiological signals for providing insight into an individual’s state of health—for example, cancer tends to elevate body temperature, while hypothyroidism lowers it. To address the need for wearable temperature sensors, researchers from the State Key Laboratory of Precision Measurement Technology and Instruments at Tsinghua University in China have developed stretchable polymer-optical-fiber-based temperature sensors that can maintain stable performance, even with large strain deformations (up to 80%).

While wearable temperature sensors have been developed using pyroelectric detectors, resistive temperature detectors, and thermistors, these designs typically have poor biocompatibility due to the use of metallic components and are susceptible to electromagnetic interference. Instead of relying on electronic strategies, the Tsinghua researchers use thermal-sensitive upconversion nanoparticles (UCNPs) embedded in a polymer-based optical fiber fabricated from stretchable polydimethylsiloxane (PDMS) elastomers. The UCNPs are only several tens of nanometers in diameter and the polymer fiber is about 1 mm across.

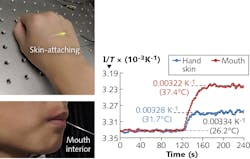

When subjected to near-infrared illumination, the UCNP-embedded PDMS fiber provides thermal-sensitive dual emission for ratiometric temperature sensing (linear range: 25–70°C) while simultaneously serving as flexible light guides for laser delivery and emission collection. Readout of the optical temperature sensor is self-calibrating, and its performance has been verified in actual measurements of skin and mouth temperature, as well as thermal signals generated by nose breathing. Reference: J. Guo et al., Adv. Funct. Mater. (2019); https://onlinelibrary.wiley.com/doi/abs/10.1002/adfm.201902898.

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.