Bridging the gap: Affordable laser research tools revolutionize academia and industry

Editor's note: Listen to our podcast interview with TAU Systems' vice president of business development Catalin Neacsu below, which we released on October 8, 2024.

The realms of academia and industry often face unique challenges when it comes to research and development. My role as CEO of TAU Systems based at the University of Texas straddles both worlds, which gives me a clear view of the challenges faced by industries in expediting research and gaining access to expensive research tools like accelerators and accelerator-driven x-ray sources, ultrahigh intensity laser systems, and advanced imaging machines.

Similarly, I can recognize the obstacles academic researchers encounter while striving to push the boundaries of technology, especially during the transition from fundamental to applied research and from applied research to product development.

Despite efforts to become multidisciplinary in many fields, it is still exceedingly difficult to bring to bear people from different professional backgrounds on a single project. Physics departments hire and train physicists, biology departments biologists, engineering departments their various sub-disciplines from mechanical to computer to software engineering, and so on. It is very difficult, for example, to hire a software engineer in a physics department to work on a control interface for a next-generation instrument. Nevertheless, academics endeavor and are crucial to keeping Moore’s Law alive by developing ever smaller and 3D stacked semiconductors or new, bespoke drugs and conducting cutting-edge research into the next generation of battery technology.

Meeting the challenges

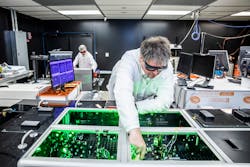

Our company, TAU Systems, is developing laser-driven particle accelerators and x-ray light sources for industrial and research applications. Using a process called laser-wakefield acceleration (LWFA), we use a laser pulse propagating in a plasma to accelerate electrons to close to the speed of light. Herein, the copper structures of conventional accelerators are replaced by plasma, and the accelerating radio-frequency fields are replaced by laser fields up to a million times stronger, allowing us to shrink the acceleration distance from many kilometers to mere centimeters and fit the whole machine into a regular laboratory room rather than a campus-sized facility.

Our long-term vision is to develop LWFA-driven free-electron lasers (FEL) ranging in wavelength from the extreme ultraviolet (EUV) to hard X-rays. These ultrabright sources currently exist at just a few kilometer-scale, billion-dollar facilities around the world, but LWFAs have made it possible to reduce the size and cost of FELs by orders of magnitude while still maintaining around 80% of the capabilities of the larger laser systems. The fundamental physics of this has been demonstrated by multiple groups in the field.

The challenge now lies in achieving the same beam quality as conventional accelerators and similar light output to drive applications, including scattering, imaging, and even lithography. Expanding access to these facilities will rapidly accelerate the rate of discovery in a wide range of fields, including biology, chemistry, physics, medicine, material science, and more.

At present, synchrotrons and FEL sources are the only sources capable of carrying out many measurements required to advance many of these fields. LWFA-driven light sources can significantly improve this situation. There are numerous applications of LWFA light sources, including metrology and, ultimately, fabrication for the semiconductor industry, protein crystallography, and time-resolved chemistry. The system also has applications of interest for academic users in high-energy density physics and national security as represented, for example, through the Department of Energy’s LasernetUS program. Applications include but are not limited to radiography of dense materials, spectroscopy and imaging of dense (fusion) plasmas, and more.

Expanding access

My industry experience has given me first-hand insight into the challenges faced by companies striving to accelerate their research efforts. Limited access to imaging equipment—particularly the expensive machines like accelerators and light sources—often becomes a bottleneck. The cost of utilizing and getting time on such equipment can be prohibitive, leading to delays in experimentation and innovation. The need for cost-effective alternatives becomes apparent as companies aim to optimize their research processes and compete in rapidly evolving markets.

TAU offers industry the opportunity to buy “beam time” and expedite research, or in the coming years, even purchase compact laser-driven x-ray and neutron sources and imaging stations and install them in their premises. The cost of accessing and operating laser-plasma-based imaging machines will fall rapidly as they become more readily available.

The reduced cost of access not only allows smaller organizations to participate in advanced research but also empowers larger companies to allocate their resources more efficiently, enabling them to undertake multiple projects simultaneously. It also provides an entry point for threshold countries for whom large particle accelerators have so far been out of reach to participate in cutting-edge research and employ them for their own specific needs, especially since purpose-focused, compact laser-plasma accelerators will be operated by a small team rather than the large divisions that run traditional accelerators. This democratization of research tools has the potential to foster greater innovation, collaboration, and accelerated product development.

Affordable laser research tools, such as TAU’s, can play a pivotal role in academia by providing a cost-effective alternative. These tools offer a significant portion of the capabilities of their larger counterparts, allowing researchers to conduct experiments, analyze data, and push the boundaries of their fields without exhausting their limited budgets. By bringing advanced research capabilities within the reach of academic institutions, these affordable laser tools empower researchers to advance their projects more quickly, collaborate more effectively, and explore novel areas of inquiry.

TAU is presently engaged in collaborations with researchers at the University of Texas at Austin and the Lawrence Berkeley National Laboratory to develop LWFA-generated light sources, and over the next year, TAU will break ground on its first service center for industrial and academic light-source customers.

About the Author

Bjorn “Manuel” Hegelich

Founder and CEO, TAU Systems

Bjorn “Manuel” Hegelich is an associate professor of physics at The University of Texas at Austin, as well as founder and CEO of TAU Systems (also in Austin, TX).