From the beginning of his career, Lieven Penninck, founder and CEO of PlanOpSim (Melle, Belgium), was noticed for his strengths in modeling and simulation. Working with organic light-emitting diodes (OLEDs), liquid crystals, and other materials and evaluating how to model them efficiently, Penninck gained expertise in tackling complex issues.

This challenge for finding just the right approach ultimately led him to spin up PlanOpSim, a company targeted at solving complicated design and integration problems by providing single workflow design software for planar and metaoptics. The reason for the foundation of PlanOpSim are multifold, but the fact that the interest in the market for metaoptics and metasurfaces was growing rapidly played a significant part.

The great unknown

Getting to this point of entrepreneurship wasn’t a direct path—and this aspect of discovery and exploration is precisely what drove Penninck. In metamaterials, everything that seems possible from a physical perspective must be interpreted and evaluated by a manufacturer to determine if it’s viable from a manufacturing perspective. It’s about opening the world up to a host of innovative ideas and redefining what’s possible.

As Penninck points out: Things that seem impossible now might be commonplace five years from now, and that sheer potential is what motivates him to look at the world in diverse ways. In metamaterials in particular, the fundamental concept comes down to the fact that if you tune a structure right, you can fabricate materials that haven't existed.

So it’s not surprising that in Penninck’s first post-Ph.D. role, he found himself a part of a team at TPVision where he worked on liquid-crystal displays (LCDs), which became a fast success story in Europe. In this role, he also realized a key truth of modeling: Complexity that goes into a product doesn’t come from one thing that is super complicated, but it comes from a million tiny things that come together. If you look at them in isolation, they aren’t inherently difficult, but because they’re all constantly interacting and influencing the solution, issues emerge that require tradeoffs. And this is what makes modeling really complicated: There are always new possibilities to explore and new difficulties to address.

Penninck’s time at TPVision provided firsthand experience in a corporate environment where R&D was critical to business success—a different perspective compared to working in an academic research lab. He was able to explore how products like LCDs impacted the end-user, which is a rare experience for a recent Ph.D. graduate. He wasn’t designing for scientists; he was developing for the consumer.

Going global

With this experience behind him, it wasn’t long before Penninck decided to seek more. He’d always lived in Belgium and had a desire to go from being a local engineer to an international one, so when a position came up at Fluxim AG in Switzerland, he took it.

This shift brought him back to the technology he grew up with—working on OLEDs—and combined this knowledge with new skillsets he needed to master in a customer-facing position. Much of his work focused on how to best apply the technology for specific applications, as well as working on business development, creating relationships with international distributors in Japan, Korea, Taiwan, India, and more.

Penninck describes this experience as eye-opening, moving from a small, specialized field in modeling to an international business. It piqued his interest in entrepreneurial endeavors, but he wasn’t yet ready to launch a company of his own. Instead, he applied himself to the work at hand and gained newfound client service expertise. It was then he realized he could model the whole chain by simply connecting the right models in the right ways and building a singular approach.

Working with metamaterials

Ultimately, this spark took hold and Penninck launched PlanOpSim in 2018, just five years after receiving his Ph.D. He was drawn to deeper work with metamaterials, because with metamaterials, he had control over what was inside, giving shape and tuning it to create a needed property, with the potential to solve numerous modeling challenges.

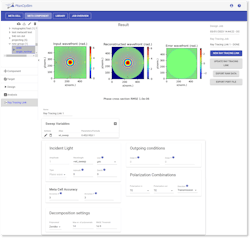

The goal of creating PlanOpSim was to empower researchers in both companies and research institutes to find their solutions in a way that combines modeling expertise with design potential (see figure). Companies use their software to design across the modeling process. To render results as smoothly as possible, PlanOpSim allows client companies to choose their materials and structures and create fabrication files that can go directly to the manufacturing lab for prototype testing.

The PlanOpSim approach takes away some of the tedious tasks from the designer and allows them to focus on functionality. There are three main aspects to the process:

1. Building up the structure. This is where physics comes into play, solving questions like: “Which materials do what I want to create? Where is the light sent? Does it experience delays or resonances? Is it reflected or transmitted in each scenario?” This is the core benefit of metamaterials: The material design is there to tune the structure until it has the desired property.

2. Advancing functional structures. In the next stage, the team will start placing structures to achieve multiple functions. Techniques of dispersion engineering are applied to help control how the material changes, how it influences other components, and how new interactions emerge. These elements are all calculated in detail.

3. Evaluating on a larger scale. From there, the build continues, and the team can analyze and design at a larger scale. In classical modeling approaches, calculations are often limited around the 50 × 50 µm level, and it can take hours or days to simulate. But with PlanOpSim’s software, different simulation methods are applied at distinct levels. It speeds up the calculation and expands the range with the option of going to millimeter- or centimeter-scale.

This process led to success for client companies. The company’s software creates an original approach for design modeling, enabling and empowering its clients to achieve product vision in a quicker, more progressive fashion. Penninck and his team are believers in the combination of metaoptics and refractive optics in hybrid optical systems.

Advent of AI

The introduction of more advanced AI offers great new opportunities. Penninck points to the necessity of identifying the right model for the right method. And while there is no miracle solution, AI can help design at record speed. A multi-step design process gives you the ability to run scenarios and create prototypes with AI— streamlining time constraints and costs in moving to mass production.

But Penninck isn’t worried AI will replace designers. Rather, he believes AI will become a very powerful tool in the hands of skilled designer. He references the parameters that must be in play and the instinct that only comes with an experienced optical designer. The designers’ honed instinct to change a parameter or influence lenses—will remain critical because of the huge design space in scientific and engineering investigation and discovery.

In this sense, he sees an even greater future for modeling and simulation to help feed and train these AI models. The best source for this input is modeling simulation. For instance, engineers can’t produce the millions of data points needed to train AI models by experiment, but they can use simulation to generate data that’s then captured in an AI model to gain efficiency in future designs.

Differentiating in a big sea

What’s next for PlanOpSim? As a startup going up against big industry players, differentiation continues to be a priority. For Penninck, it means offering a personalized service to take their software from a solution to a relationship-based support system.

In a field as technical as nanophotonics, expertise beats product in many cases; knowledge is so much more than a piece of software that runs calculations. What companies and designers need is a team of experts who not only can provide guidance on the calculation itself but also the technical understanding to guide product development. The PlanOpSim team has studied metamaterials in detail, and they collaborate with customers to counsel them on the best approach to solve for their challenges.

Taking the leap

Penninck offers words of encouragement for the next generation: Take the leap. In his experience, the biggest, hardest part of starting a company is making the jump. Before you do it, it’s scary and there are reasons not to. But once you’ve jumped, you figure out a way to start swimming. It may seem uncertain at first, but you will never run out of ideas, possibilities, and things to improve. He advises not to worry about uncertainty, just focus on continuously taking the next step forward.

For Penninck, the technical skills of modeling mirror the path of his career: Diving deep to solve for an unknown. Whatever the future may hold, he will continue to focus on understanding the fundamentals and possibilities within the nature of physics and optics. Metaoptics are one of the best fields to do so.

About the Author

Jose Pozo

Chief Technology Officer, Optica

Jose Pozo joined Optica in March 2022, and has spent more than 25 years working in photonics. He earned a PhD in quantum physics from the University of Bristol (U.K.), and an M.Sc. and B.Eng. in telecom engineering from UPNA, Spain / VUB (Belgium). Prior to joining the European Photonics Industry Consortium (EPIC) in 2015 as CTO, Jose was a Senior Photonics Technology Consultant with PNO Consultants, with some of the main accounts such as CERN, Thales, and TE Connectivity. He has worked at TNO, The Netherlands Organization for Applied Scientific Research, and as a postdoctoral researcher at the Eindhoven University of Technology in the Netherlands, where he contributed to the early development of EFFECT Photonics.