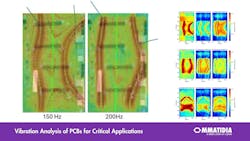

Vibration Analysis of PCBs for Critical Applications

Printed circuit boards (PCBs) used in space, defense, aeronautics, and transportation cannot tolerate in-service failures. Before deployment, these systems must pass environmental qualification tests, including vibration, shock, thermal cycling, radiation, EMC, and ingress protection. PCB failures often arise from solder joint cracking, component detachment, pad delamination, or trace fracture — linked to dynamic response under vibratory loading. Understanding how PCBs actually deform under load is essential to uncompromising reliability.

Limitations of Accelerometer-Based Testing

Standard accelerometers measure overall board motion but cannot capture vibrations at individual components, where failures originate. Populated PCBs are complex, with varying mass and stiffness from components, solder joints, and copper traces, making modeling and simulation uncertain. Conventional scanning LDVs capture one point at a time, requiring repeated excitations and risking missed localized behaviors.

Ommatidia’s Massively Parallel Laser Vibrometry

Ommatidia’s approach combines Laser Doppler Vibrometry with Laser RADAR and interferometric measurement to capture dozens of points simultaneously. This method provides:

-

Non-contact measurement with no mass loading or wiring

-

High spatial resolution across the PCB

-

Synchronous data without repeated sweeps

-

Clear visualization of component-level vibration

It is ideal for environments with random or sine vibration, launch loads, weapons recoil, high-speed rail dynamics, or continuous fatigue.

Test Insights

A populated PCB mounted on a linear shaker was excited from DC to 600 Hz. 65 simultaneous LDV points revealed resonance peaks at 150 Hz, 200 Hz, and 250 Hz. Component placement altered local deflection patterns and nodal lines, showing where solder fatigue, pad delamination, or fractures are most likely.

Why It Matters

This high-density data enables early detection of failure-prone areas, better correlation between simulation and real hardware, and PCB layout optimization for harsh conditions. Engineers can

now see how real hardware behaves under load without added mass or wiring, supporting reliability in critical applications.

Learn more about Vibration Analysis of PCBs for Critical Applications on Ommatidia’s website.