Design for Manufacturing Case Study

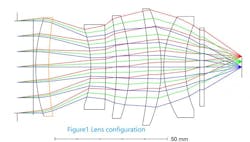

A scientific device and instrument company needed to develop an infrared lens with focal length of 40mm and f number of 0.98 for spectral imaging application. The spectral imager was meant to measure the relative concentrations of elements and compounds in fluid enabling precise monitoring firefighting applications. This required a precision lens with very little distortion.

Although the original design from this scientific device and instrument company offers high imaging quality and small distortion, it was not designed with an eye for manufacturing constraints. They originally used aspheric lens elements and a hazardous material (GaAs) to improve the modulation transfer function (MTF) and correct the chromatic aberration. Comparing with spherical lenses, the fabrication cost of aspherical lenses is higher. Using the toxic material GaAs can significantly increase the difficulty level for fabrication and incur unnecessary manufacturing cost.