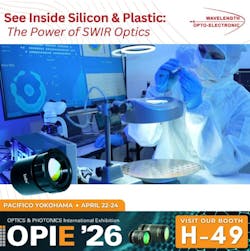

See Inside Silicon & Plastic: The Power of SWIR Optics

Standard vision systems cannot detect defects inside silicon, rot beneath fruit skin, or liquid levels inside opaque plastic. To catch these issues, you need Short-Wave Infrared (SWIR).

Operating at 0.9 – 2.5 µm, SWIR delivers the high-contrast images required for precision inspection. However, standard visible lenses fail at these wavelengths. You need SWIR-optimized optics.

Critical Inspections Enabled by SWIR

1. Semiconductor Inspection: Silicon is transparent above 1150 nm.

SWIR reveals internal cracks and voids in wafers instantly, without destructive testing.

2. Food Quality Control: Water is highly absorptive in the SWIR spectrum.

Bruises and rot appear as dark spots, allowing automated sorting before products ship.

3. Fill Level Detection: Many opaque plastics are transparent to SWIR.

Cameras verify liquid levels or count tablets inside sealed, colored containers without opening them.

To achieve this precision, your lenses must be optimized for SWIR transmission. Standard glass introduces aberrations.

Consult our team for a custom SWIR Lens now.