Infrared Lens Design: Shaping Advanced Imaging

In the realm of cutting-edge imaging and sensing technologies, the significance of infrared lens design and assemblies cannot be overstated. These technologies have found widespread use across a wide variety of applications, including night vision, thermal imaging, and long-range surveillance.

The design and assembly of infrared lenses involve a range of optical systems that are tailored for various wavelength ranges. For instance, long-wave infrared (LWIR) cameras detect thermal radiation in the 8-12 µm wavelength range, while mid-wave infrared (MWIR) cameras detect radiation in the 3-5 µm range and short-wave infrared (SWIR) imaging operates in the 0.9-1.7 µm range.

For any infrared imaging system, the most vital component is the camera core, which contains the imaging sensor. Such camera cores commonly utilize uncooled thermal imaging sensors (typically based on microbolometer technology) which detect thermal radiation without requiring cooling, making them ideal for use in portable and low-power systems.

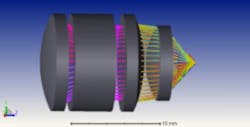

The lens assembly is typically built from materials transparent to infrared radiation. These include substances such as germanium, silicon, and zinc selenide – materials marked by their distinctive optical properties that make them suitable for use in infrared optics (high refractive indices, low dispersion, and good transmission in the infrared wavelength range).

The focal length of an infrared lens assembly is critical to the overall performance of the camera. A longer focal length improves the camera’s long-range detection capabilities, whereas a shorter focal length provides a wider field of view (FOV).

Beyond just the lens assembly, infrared cameras also include other optical components like filters and mirrors. These additional elements serve to regulate the spectral response and elevate the overall performance of the camera.

One important development in the field of infrared imaging is the application of InGaAs sensors to SWIR imaging. These sensors provide improved sensitivity and lower noise compared to traditional SWIR sensors, making them optimal for use in applications like spectroscopy and industrial inspection.

Overall, the design and assembly of infrared lenses and optical systems are foundational to the performance and capabilities of infrared imaging technologies. Researchers and engineers are able to leverage these components to optimize the designs of their systems and develop advanced imaging and sensing technologies with a wide range of applications in fields such as defense, security, and medicine.