New performance record for bolometer matches speeds of high-frame-rate cameras

Thermal-image-sensor producer ULIS (Veurey-Voroize, France), which is part of the Sofradir Group, presented a technical paper at OPTRO2018 (Feb. 6 to 8, 2018; Paris, France) that outlines how the company's bolometer now meets the speed requirements of fast imaging applications. In particular, the ULIS bolometer has a response time that is four times greater than standard bolometers. ULIS says it has achieved this faster speed without any trade-off in sensitivity and that the company is the first to overcome this technological challenge as it works to raise the overall factor of merit (FoM)1 of bolometers.

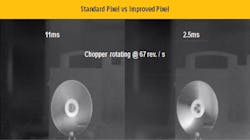

FoM, a relative measure of thermal sensor sensitivity against response rate, is a key parameter that camera makers use to compare the performance of thermal sensors. ULIS’ pixel technology achieves an FoM of 125 to 150 mK · ms. In contrast to standard bolometers, the 4X faster response time means that the bolometer can detect fast-moving objects without producing a blurred image. ULIS says that this (along with the bolometer's relatively low price) makes the sensor well-suited for inclusion in machine-vision cameras, where high frame rates for in-line quality inspection are required but where the cost of adopting thermal imaging had previously been prohibitive. The bolometer will also have wider application in defense, such as missile warning systems, says ULIS.

"We feel camera makers will benefit tremendously from thermal image sensors, which, when used in conjunction with visible or SWIR cameras, can provide valuable additional information on product quality," says Sébastien Tinnes, marketing team leader at ULIS. "We look forward to exploring with customers, industrial partners and the scientific community attending SPIE Defense and Commercial Sensing in Orlando in mid-April, the potential of integrating this new pixel technology into future equipment requiring fast imaging capabilities."

ULIS presented its results in a technical paper called "ULIS Bolometer for Fast Imaging Applications Sets New Response Time Record" at OPTO2018. The new bolometer showed gains in FoM performance from the standard NETD = 50 mk multiplied by TTC = 10 to 12 ms (meaning FoM 500 to 600 mK · ms) to a new level of NETD = 50 mK multiplied by TTC = 2.5 to 3 ms (meaning FoM 125 to 150 mK · ms), a fourfold improvement.

At SPIE DCS 2018 (April 15 to 19; Orlando, FL), ULIS will be exhibiting at the Sofradir Group booth #806.

REFERENCE:

1. About the factor of merit (FoM): FoM is a parameter that combines sensitivity (NETD) and response Time (TTC). Response time measures how quickly the bolometric pixel membrane responds to the infrared radiation changes taking place. Sensitivity determines how well the sensor can detect an object in all lighting conditions, as well as in complete darkness. Both sensitivity and response time are linked. Traditionally, they move in counterproductive directions; reducing the response time tends to degrade sensitivity.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.