Teledyne wins $23 Million IR FPA contract for NASA’s WFIRST astronomy mission

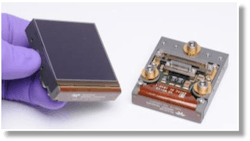

NASA has awarded Teledyne Scientific & Imaging (Camarillo, CA) a contract for the short wave infrared (SWIR) sensor chip assembly (SCA) for the Wide Field Infrared Survey Telescope (WFIRST) project underway at the Goddard Space Flight Center (Greenbelt, MD). Parent company Teledyne Technologies (Thousand Oaks, CA; NYSE:TDY) said the contract is cost-plus-award-fee with a value of $23 million. Teledyne will produce 72 SWIR SCA devices for the WFIRST Space Flight Focal Plane Assembly.

WFIRST will use 18 of Teledyne’s H4RG-10 arrays in the focal plane assembly. With over 300 million pixels, it will be the largest infrared focal plane operating in space when it launches in the mid-2020s. WFIRST will have nearly 300 times as many pixels as there are in the infrared camera of the Hubble Space Telescope, enabling it to take images that have 100 times the field of view of Hubble. The large field of view enables WFIRST to survey large areas of the sky to measure the effects of dark matter and dark energy on the distribution of galaxies in the universe.

Related: Ground-based sky survey telescopes challenge large FPA technology by an engineer at e2v

Related: Digital-pixel FPAs enhance infrared imaging capabilities by researchers at MIT Lincoln Lab

The H4RG-10 infrared array is at a mature state, advanced to NASA technology readiness level 6 (TRL-6) during a 45-month development contract that commenced in 2014. TRL-6 is the level at which components are qualified for use in the harsh environment of space. In addition to the infrared arrays, Teledyne has a development contract with NASA for the visible light detectors that will be used in the coronograph instrument of WFIRST.

Source: Teledyne Technologies

About the Author

Conard Holton

Conard Holton has 25 years of science and technology editing and writing experience. He was formerly a staff member and consultant for government agencies such as the New York State Energy Research and Development Authority and the International Atomic Energy Agency, and engineering companies such as Bechtel. He joined Laser Focus World in 1997 as senior editor, becoming editor in chief of WDM Solutions, which he founded in 1999. In 2003 he joined Vision Systems Design as editor in chief, while continuing as contributing editor at Laser Focus World. Conard became editor in chief of Laser Focus World in August 2011, a role in which he served through August 2018. He then served as Editor at Large for Laser Focus World and Co-Chair of the Lasers & Photonics Marketplace Seminar from August 2018 through January 2022. He received his B.A. from the University of Pennsylvania, with additional studies at the Colorado School of Mines and Medill School of Journalism at Northwestern University.