Commercial laser power meter by Scientech measures extremely high powers using radiation pressure

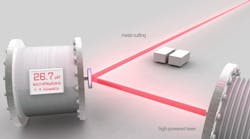

| A still from a NIST video shows a schematic depiction of a radiation-pressure-based laser power meter measuring a 26.7 μN force, the pressure induced by a 4 kW beam. Radiation pressure for a chosen beam power is independent of wavelength. (Video: NIST -- see source below) |

Scientech (Boulder, CO), a company that makes both precision electronic weighing systems and laser-beam measurement equipment, now produces an instrument that combines both of these areas of expertise -- a laser power meter that measures the amount of power in a beam reflected off a mirror by measuring the radiation pressure on the mirror. The technology, which is patented by Scientech, was developed with the National Institute of Standards and technology (NIST; also in Boulder), which demonstrated the device in 2013 with a 530 W ytterbium-doped fiber laser and a 92 kW carbon dioxide (CO2) laser.1

Acccording to Robert Lee, an engineer at Scientech and a coauthor of the NIST paper, the instrument has "achieved groundbreaking measurements exceeding 500 kW with 1% accuracy in a device smaller than a breadbox and the cost is a fraction of devices rated at 20 kW. Testing is to continue in 2016 with the goal of achieving 1 MW of continuous power." Lee adds that NIST has been using a Scientech radiation-pressure sensor to allow real-time power measurements during laser welding operations using a fiber-delivered 10 kW beam at a 1060 nm wavelength.

The Zeta weighing sensor can be calibrated in the horizontal plane using an offset weighing component and then oriented vertically with a mirror for use with a high-power laser beam.

Sources:

1. http://scientech-inc.com/categories/laser-power-energy/radiation-pressure-sensor.html

2. http://www.nist.gov/pml/div686/laser-102213.cfm

REFERENCE:

1. P. A. Williams, J. A. Hadler, R. Lee, F. Maring, and J. H. Lehman, Optics Letters, Oct. 15, 2013; doi: 10.1364/OL.38.004248.