Research propels quantum dots forward

ADRIENNE D. STIFF-ROBERTS, SUBHANANDA CHAKRABARTI, XIAOHUA SU, AND PALLAB BHATTACHARYA

High-operating-temperature (over 150 K), infrared photodetector arrays will reduce the cost of IR imaging systems by allowing cryogenic Dewars to be replaced by thermoelectric coolers. While quantum-dot IR photodetectors (QDIPs) are well-suited for detecting mid-IR light at elevated temperatures, their benefits are not without technical challenges. A quantitative comparison of QDIPs to other IR-detection technologies highlights the unique aspects of quantum dots. A review of state-of-the-art, high-operating-temperature QDIPs reveals the future research steps that are necessary for continued improvement of this technology toward eventual commercialization.

Potential applications

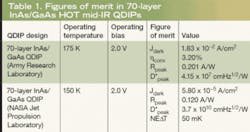

The quantum dot is a promising nanostructure for high-operating-temperature (HOT) IR photodetection. Quantum dots feature three-dimensional quantum confinement and offer several advantages for device operation. Successful demonstration of low-dark-current, multispectral response, high-detectivity, HOT photodetection, and IR imaging in QDIPs has helped establish them as a viable alternative to microbolometers and mercury cadmium telluride (HgCdTe) photodiodes for imaging applications in the mid-IR.1-8 In addition, HOT, mid-IR QDIPs could prove ideal for specialized applications related to quantum-cascade lasers, for example. Indium arsenide/gallium arsenide (InAs/GaAs) QDIPs are also suitable for IR-camera focal-plane arrays operating at 150 K in the mid-IR (see Table 1).

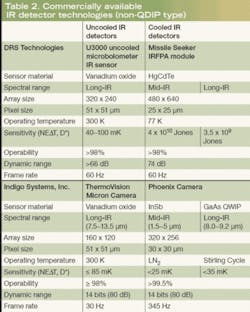

It is important to note that, when compared directly to commercially available cooled and uncooled detector technologies (see Table 2), InAs/GaAs QDIPs (at 150 K) have already demonstrated performance comparable to HgCdTe photodiodes (at 77 K) in the mid-IR. Therefore, QDIPs are positioned to become an important, alternative technology for the niche market of HOT, mid-IR photodetectors from 3 to 5 µm, which could prove to be the third commercial application for epitaxially-grown quantum dots, following laser diodes and semiconductor optical amplifiers.Benefits and challenges

The quantum-mechanical nature of the QD yields several advantages for IR photodetectors compared to higher-dimensional materials, including normal-incidence detection, large excited-state electron relaxation times for increased detector efficiency, several tuning parameters (shape, size, strain, and material composition) for controlling optoelectronic properties, and low dark current for HOT IR photodetection.

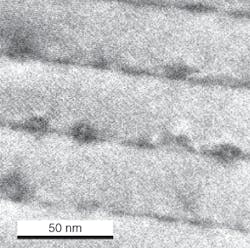

The Stranski-Krastanow (S-K) growth mode is an epitaxial technique used to synthesize active-region heterostructures that are quantum-confined in three dimensions, such as QDs. Stranski-Krastanow QDs are synthesized using strained-layer epitaxy in ultra-high-vacuum crystal growth systems like molecular beam epitaxy (MBE). Coherently strained, three-dimensional InAs islands form on the GaAs substrate surface after the two-dimensional, layer-by-layer growth of a strained, InAs wetting layer (see Fig. 1). The QDIPs use an extrinsic IR-detection scheme in that the reduced dimensionality of the active region enables intraband absorption of incident radiation. In general, the two types of intraband transitions that can originate in the QD are bound-to-bound transitions in which ground-state electrons are photoexcited to the excited state of the QD, and bound-to-continuum transitions in which an electron in the ground or excited state is photoexcited out of the QD into the continuum of energy levels for the barrier bulk material.The intraband absorption mechanisms require the presence of electrons in a bound state of the QD. Electrons can be introduced in the QD by direct doping, modulation doping, or capture of injected electrons from the device contact. It has been shown that QDIP performance has a distinct tradeoff between, and dependence on, QD density and dopant concentration.9 For higher dopant densities, the dark current increases, and for lower dopant densities, the absorption efficiency decreases.

It is a challenge, however, to precisely control this dopant incorporation during S-K growth. In fact, one of the most significant consequences of the S-K growth mode is the random fluctuation of dot size, material composition, and doping. This nonuniformity of QDs leads to an inherently large full-width half-maximum (FWHM) linewidth (approximately 50 meV) for transitions in a QD ensemble, which has a deleterious effect on QDIP performance. Thus, the epitaxial growth and design of QD heterostructures is one of the most important issues related to obtaining state-of-the-art performance in QDIPs and to establishing QDIPs as a mature technology.

QDIPs vs. commercial technologies

Despite the challenges associated with QDIPs, these detectors possess two important characteristics that motivate their investigation and distinguish them from state-of-the-art thermal detectors such as microbolometers and low-bandgap photodiodes (such as HgCdTe). First, while thermal detectors operate at room temperature and are inexpensive, lightweight, and commercially available, IR photodetection is still preferred for advanced applications requiring high resolution and fast modulation response. Quantum-dot IR photodetectors can detect multiple wavelengths of light simultaneously in a single device heterostructure, thereby increasing the resolution, and they have a faster response to changing input since the carrier lifetime is not limited by diffusion (which is typically a slow mechanism). Second, QDIPs have demonstrated comparable performance to low-bandgap, HgCdTe photodiodes at higher operating temperatures (see Table 1 and 2). This HOT IR photodetection is very important in reducing costs associated with IR cameras and in identifying new applications for IR photodetectors.

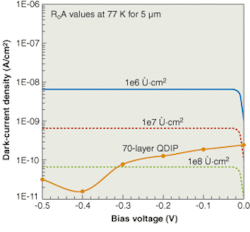

Because the QDIP is an intraband detector, it differs in its principle of operation and materials requirements from interband HgCdTe photodiodes. In HgCdTe photodiodes, for example, the dark current is primarily diffusive and depends inversely on the minority carrier lifetime (τcarrier ~ 10 µs). However, the dark current in a QDIP is determined primarily by thermionic emission and field-assisted tunneling rates (τcarrier ~ 100 ps to 1 ns). The interpretation of the RoA product (product of differential resistance Ro and optical area A) also exhibits subtle, but important, differences. In a photodiode, the RoA product has a constant value, is an intrinsic property of the material related to the dark current, and depends on the cutoff wavelength of the bulk material. But, for the QDIP, the RoA product depends on the device geometry and does not display any consistent wavelength dependence. As a result, a more meaningful parameter for comparison is the dark-current density (see Fig. 2), which is much smaller in a 70-layer QDIP at 77 K than in a HgCdTe photodiode (derived from measured RoA values obtained from Rockwell Scientific).HOT mid-IR photodetection

Two QDIP device designs that have pushed the limits of HOT IR photodetection are the 70-layer QDIP and the resonant tunneling QDIP.

The most important feature of the 70-layer QDIP is the increased absorption in the active region. To absorb 50% of incident light at peak frequency, the required QD absorption-region thickness corresponds to 40 to 60 uncoupled dot layers. Because of the high strain inherent in S-K QDs, the growth of large QD stacks is a challenge—a large dislocation density would significantly degrade absorption and QDIP performance. Using MBE, the growth conditions and heterostructure design can be optimized to grow a large number of dot layers without degradation of the material quality. These include substrate temperature cycling to provide in-situ annealing of QDs to improve the GaAs barrier material quality, and a minimum barrier thickness of 40 nm between dot layers to prevent dislocations and to help reduce thermionic emission and tunneling contributions to the dark current. The device figures of merit indicate that this 70-layer QDIP provides HOT IR photodetection due to the simultaneous reduction of dark current by the GaAs barrier and the increase of responsivity by the 70-layer, QD absorption region.

Another approach to reduce dark current and increase operating temperature in QDIPs is to use resonant tunneling filters to selectively block dark current while transmitting photocurrent.10 When the thickness and position of a double aluminum gallium arsenide (AlGaAs) barrier are properly designed around a QD layer, the electron tunneling probability is approximately 1 at a particular energy corresponding to the desired peak detection wavelength. At the same time, the tunneling probability is several orders of magnitude lower for energies that are several meV removed from the peak energy. Because dark current is due to electrons with a broad energy distribution, dark current will be significantly reduced by the resonant tunneling filter.

Current research

Several other S-K QD material systems are being investigated as the active region in IR photodetectors. In addition to the standard InAs/GaAs QD system, InAs QDs have been embedded in strain-relieving InGaAs quantum wells to form dot-in-a-well (DWELL) heterostructures. These DWELL QDIPs not only permit greater control over wavelength tunability, but they have also demonstrated excellent device performance.

Promising device performance has been demonstrated for QDIPs using an undoped active region of InAs QDs grown directly on AlGaAs with a GaAs cap layer. Other III-V material systems under investigation include InAs/indium aluminum arsenide (InAlAs) QDs grown on indium phosphide (InP) and InGaAs/indium gallium phosphide (InGaAs/InGaP) QDs grown on GaAs.

Intraband transitions in the IR have also been observed for germanium and silicon QDs. These boron-doped devices use holes trapped in the QD valence band for the photogeneration of carriers, and the characterization of germanium and silicon QDIPs indicates they may be an important technology for far-IR detection (greater than 14 µm).11 As QDIP technology continues to mature through research, commercial applications in HOT, mid-IR photodetection will be realized.

REFERENCES

- S. Y. Wang et al., Appl. Phys. Lett. 78, 1023 (2001).

- S. Krishna et al., Appl. Phys. Lett. 82, 2574 (2003).

- U. Sakoglu et al., J. Opt. Soc. Amer. B 21, 7 (2004).

- J. Jiang et al., Appl. Phys. Lett. 84, 2166 (2004).

- J.-W. Kim et al., IEEE Electron Device Lett. 21, 329 (2000).

- S. Chakrabarti et al., IEEE Phot. Tech. Lett. 16, 1361 (2004).

- J. Jiang et al., Appl. Phys. Lett. 84, 2232 (2004).

- A. D. Stiff-Roberts et al., Appl. Phys. Lett. 80, 3265 (2002).

- J. Phillips, J. Appl. Phys. 91, 4590 (2002).

- X. H. Su et al., Electr. Lett. 40, 1082 (2004).

- A. I. Yakimov, J. Appl. Phys. 89, 5676 (2001).

Adrienne D. Stiff-Roberts is assistant professor in the Department of Electrical and Computer Engineering at Duke University, Durham, NC 27708-0291; Subhananda Chakrabarti is research fellow, Xiaohua Su is graduate research assistant, and Pallab Bhattacharya is Charles M. Vest distinguished university professor and James R. Mellor professor of engineering in the Department of Electrical Engineering and Computer Science at the University of Michigan, Ann Arbor, MI 48109-2122; e-mail: [email protected].