DETECTORS: Photodiodes no longer stand alone

KEN SINCLAIR

Photodiodes and photodiode arrays are still the most common photodetectors in applications ranging from medical diagnostics and barcode readers to military guidance systems and telecommunications. They offer compact size, ruggedness, solid-state reliability, low noise, and low cost.

Today, many OEM customers for these devices specify some type of integrated assembly or optoelectronic hybrid, rather than a stand-alone photodetector. These assemblies range from simple packages to fully integrated photodetection systems with sophisticated signal amplification and processing electronics. Photodetector subassemblies have all components preassembled, aligned, and fully tested, making them cost-effective in applications as diverse as automated determination of corrective optometric prescriptions and high-performance particle-counting systems.

Optics options

An integrated photodetector subassembly can include several types of optics. The most common is a protective window that prevents dust and other contaminants from reaching the surface of the photodiode. Such contamination could directly reduce optical efficiency and produce surface-leakage current in certain types of photodiodes. The majority of these windows are hermetically sealed to a metal can or package.

Filters are used to modify the wavelength response. For example, in lamp-based applications that measure ultraviolet signals, it is common practice to use a hot mirror in front of the photodetector to deflect unwanted infrared light that would otherwise create runaway dark current (background noise). It is also fairly routine to incorporate some type of bandpass filter when a wavelength-specific signal, such as from a laser, must be detected against high ambient light. In some instances, this wavelength selectivity can be provided by Filtrode technology, patented by Advanced Photonix, in which a multilayer coating is directly deposited on the surface of a silicon photodiode.

Lenses can be used to change the detector field of view or to increase the energy density (and hence the signal-to-noise ratio) at the detector. Other types of optics include diffusers that destructure incoming light and avoid local saturation of a detector and prisms to change the input angle according to the demands of overall system geometry.

Electronic elements

The transimpedance amplifier (TIA) has long been the most common device used for first-stage amplification of the electronic signal from a photodiode, whether operated in a photovoltaic or photoconductive (reverse bias) mode. This relatively simple circuit uses an optical amplifier to provide high input impedance while maintaining high-speed response. Not surprisingly, the TIA is also the amplifier of choice in assemblies to amplify a weak signal above the noise floor of downstream electronics. Moreover, if this TIA is included with the photodetector in one hybrid package, it precludes any problems with antenna pickup effects.

Many sophisticated assemblies also include added electronic functionality, such as secondary amplification, A/D converters, and signal processing components such as sample-and-hold amplifiers and multiplexing circuitry. Secondary amplification may be necessary in applications that produce particularly low signals that could not be amplified to acceptable levels in a single amplifier without distortion (loss of signal fidelity).

The sample-and-hold circuit is a signal-integration device common in applications that produce a stream of pulsed or transitory signals. The circuit, which is usually self-triggered, integrates over the entire light pulse and holds the sum value until these data are accessed by subsequent electronic devices. The circuit then automatically resets to zero ready for the next light pulse.

Some assemblies contain tens or even hundreds of individual detectorseither as separate photodiodes or as multipixel arrays. These devices often use multiplexing circuitry to provide sequential access of individual signals using only a limited number of interconnects. In addition, secondary signal processing may often include sum, difference, or ratio amplification to simplify the conversion of raw signals into usable information.

Finally, the advent of low-cost digital signal processing (DSP) chips has led to the development of "smart" photodetector assemblies, with adjustable programmable properties for maximum flexibility.

Configuration and packaging

Military applications are no longer the primary market for custom-shaped and packaged detectors. With an emphasis on ever-smaller electro-optic products, particularly in the consumer sector, demand for space-saving technologies such as flip-chip and flex circuits continues to grow rapidly.

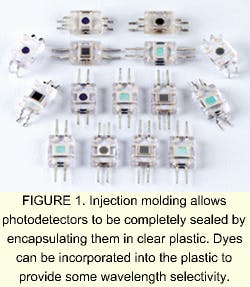

A flip-chip photodiode has both electrodes on the front side. These are bonded directly to a circuit board or substrate by bump bonding or reflow solder, rather than by traditional wire bonding. This minimizes the area of the circuit board occupied by the photodiode. Flex circuits replace the stiff circuit board with a flexible multilayer ribbon, allowing the assembly to fit in a convoluted or small space. Still popular as a packaging method is glass-to-metal hermetic sealing, which prevents physical or environmental damage. But as more photodiode manufacturers acquire dedicated injection-molding technology, the cost-competitiveness of this option has grown. Here, the photodiode is completely encapsulated in clear plastic, making for a very rugged product (see Fig. 1). Furthermore, dyes can be incorporated into the plastic to provide some wavelength selectivity.To better understand the need for some of the diverse functionality just discussed, it is useful to examine two applications that make use of photodiode assemblies with very different levels of complexity and integration.

Practical particle counting

Pacific Scientific Instruments (Grants Pass, OR) is the world's largest manufacturer of particle-counting systems for both airborne and liquid applications. Typical uses include measuring cleanroom particulate levels in the semiconductor and pharmaceutical industries and checking for particulates in deionized water used in semiconductor fabrication. Other common applications include measuring the efficiency of filters used by water-processing plants to trap harmful parasites and looking for particles in hydraulic oil samples from heavy commercial and military equipment. Depending on the application, the target detection window is for particle diameters ranging from 0.03 µm to several microns.

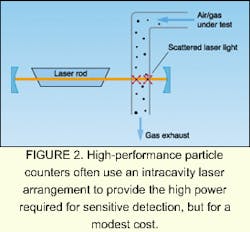

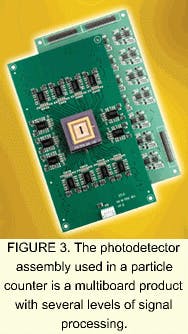

Particles are detected by their scattering effect on incident laser light. New high-sensitivity systems for airborne detection perform the particle counting within a solid-state laser cavity (see Fig. 2). An intracavity laser provides the high power (up to 1 kW) required for sensitive detection, but for a very modest cost. In operation, air samples flow through a nozzle and are directed across the laser beam to an exit port. Any particles result in laser scatter, which is collected at 90° to both the beam and the airflow and imaged onto a one-dimensional photodiode array.This smart detector assembly also incorporates DSP chips. "The high performance required by the semiconductor industry dictates that the particle detection efficiency be uniform across the entire field of view," Girvin says. "In practice, though, there are spatial variations in system detectivity due to imperfect laser collimation, divergent airflow, and aberrations in the detection optics. We can rigorously calibrate and compensate for these variations as follows. A reference gas with known particle content of a specific size is subjected to the instrument at our factory. The DSP chips then adjust the gain on each of the 48 separate TIAs to ensure a spatially invariant response."

Eyesight diagnostics

A very different type of assembly is used in an autorefractor from Zeiss Humphrey Instruments (Dublin, CA). The Acuitus instrument automatically determines corrective eyesight prescriptions. Here the critical aspects of the photodetector assembly are the novel shape and precise geometric arrangement of the photodetector elements, rather than complex electronics.

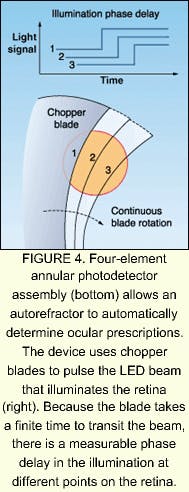

William Burnham, product marketing manager at Zeiss Humphrey, says, "Unlike conventional instruments that perform topographic measurements such as corneal curvature, the Acuitus measures the optical properties of the eye (optical power, astigmatism) as an integrated optical system, by analyzing reflections from the retina." The principle is conceptually fairly simple, he explains. Collimated near-infrared light (~800 nm) from an LED is directed at the eye. The reflection from the eye is detected by a relatively simple photodetector assembly containing four photodiodes shaped to form a segmented annulus (see Fig. 4). "The retina efficiently absorbs light and produces a relatively weak reflection," says Zeiss Humphrey optical engineer Ning Chan. "Annular detectors allow us to spatially eliminate the central part of the reflected wavefront, which is dominated by the strong reflection from the cornea."In a normal eye (20/20 vision, no astigmatism), each of the four detector segments receives light from the same spot on the retina. In an eye with some optical imperfections, though, the detectors will sample different parts of the retina. The extent and direction of these sampled region displacements are used by Acuitus to compute the exact prescription to correct the vision of each eye.

To determine these displacements, the light from the LED is chopped by a mechanical chopper. As the chopper blade sweeps across the light beam, there is a corresponding sweep of illumination across the retina. "By measuring the phase delay of the chopped detector signals relative to a reference pulse from the chopper," Chan says, "we can determine exactly how the regions sampled by the four detectors are displaced in the retinal plane."

In addition to being a time-saving tool for skilled optometrists in developed countries, Burnham predicts a growing market for Acuitus in underdeveloped countries with few highly trained optometrists. This instrument will also allow eyesight correction in patients with impaired communication skills.

Ken Sinclair is product manager at Advanced Photonix, 1240 Avenida Acaso, Camarillo, CA 93012-8727; e-mail: [email protected].