Maximizing wireless power delivery demands understanding of laser/PV characteristics

Wireless power transmission—the process of using a remote laser to irradiate a local photovoltaic (PV) cell to generate power—is becoming highly desirable for applications in unmanned aerial vehicles (UAVs) and, specifically, for battlefield applications where power is not readily available. Although most power delivery applications use 808 nm semiconductor lasers for their low cost and high electro-optical conversion efficiency to irradiate silicon-based solar cells that have high spectral response at 808 nm, this particular laser wavelength and type suffers from large divergence angles, low power, and high atmospheric attenuation, limiting its effectiveness. By expanding the study of wireless power delivery options to include temperature performance in addition to the standard output characteristics of the system, Xiaowei Li at Chifeng University (Chifeng, China) has found that alternative laser/PV combinations can be optimized for peak power delivery performance.

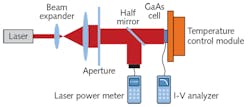

It turns out that regardless of how good a solar cell is at absorbing light of a particular wavelength, a high laser power density can raise the temperature of the cell and reduce its efficiency. By performing experiments on a 1064-nm-emitting fiber laser irradiating a gallium arsenide (GaAs) single-junction solar cell using different beam expanders and apertures to vary the spot size at the cell, Li discovered that the open-circuit voltage, short-circuit current, and other I-V characteristics of the cell can be optimized to improve power delivery output. In his particular configuration, analysis showed that as a function of input laser power and density, the energy conversion efficiency of the GaAs cell could reach a maximum of 54.5% at a laser power of 0.405 W. Reference: X. Li, Photonic Sensors, 8, 3, 228–233 (2018).

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.