Type II semiconductor superlattice photodetectors new alternative to HgCdTe

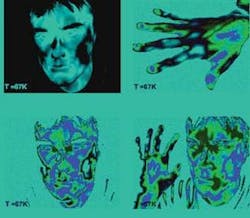

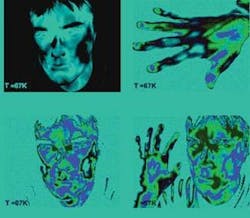

While mercury cadmium telluride photodiodes and quantum-well infrared photodetectors are well established in military and other applications, the performance of these detectors at long-wave infrared (LWIR) and very-long-wave infrared (VLWIR) wavelengths is limited due to difficulties in producing uniform material. In an invited talk at SPIE’s Defense + Security Symposium March 17 (Orlando, FL), Manijeh Razeghi, professor of electrical engineering and computer science at Northwestern University (Evanston, IL), announced that Type II indium arsenide/gallium antimonide (InAs/GaSb) photodetectors may now be an important alternative to existing detectors at these wavelengths. Razeghi and her team fabricated Type-II InAs/GaSb superlattice photodiodes by growing multiple layers of Type II materials via molecular-beam epitaxy, enabling precise control of the cut-off wavelength from 3.7 to 32 mm.

The group created photodiode arrays up to 400 mm2 in size with external quantum efficiency (QE) greater than 50% at a 9 mm wavelength. With optimized antireflective coatings, the single-pass QE could exceed 75%, says the group. The single-element detectors and arrays featured decreased dark current and increased sensitivity, and functioned as two-color detectors in LWIR with the differential resistance and QE of single-band devices. Contact Manijeh Razeghi at [email protected].