FOURIER-TRANSFORM HOLOGRAPHY: X-ray holography gets a boost from an old idea

Some ideas just get better with age. The pinhole camera, standby of the Renaissance greats, has a new incarnation that looks set to revolutionize x-ray holography. The new method can be refined to provide resolution down to a few nanometers and requires x-ray exposures of just femtoseconds.

The new technique was used to create the brightest, sharpest x-ray holograms of nanoscale objects ever produced.1 Fittingly, one of the initial holograms is of Da Vinci’s famous Vitruvian Man.

The idea is the brainchild of Stefano Marchesini, now based at Advanced Light Source at Lawrence Berkeley National Laboratory (Berkeley, CA). “A pinhole camera creates an image of an object convolved with the pinhole. Big pinholes mean low resolution, small pinholes mean high resolution,” explains Marchesini. “Unfortunately the image brightness has the opposite behavior: there is a tradeoff between brightness and resolution. Even though pinhole cameras use the particle nature of light, and holography uses its wavelike properties, the tradeoff between image brightness and resolution has the same characteristics.”

Such pinhole illumination schemes have been used in Fourier-transform holography in the visible, and multiple separate pinholes have even been used to increase the brightness of images without compromising resolution. Image reconstruction and imaging geometry, however, become increasingly difficult using such approaches.

Coded apertures

Gamma-ray astronomers have been using “coded apertures” for years as a means to image using high-energy sources without focusing optics. Their so-called uniformly redundant arrays lean on the pinhole camera idea too: arrays of regularly spaced holes allow more light in, but the image has to be reconstructed using a computer to decode the overlapping images from each individual hole.

Marchesini hit on the idea of combining such a coded aperture with x-ray holography, maintaining the inherent resolution of the process with orders of magnitude more brightness. He made use of the Berkeley Lab’s Center for X-ray Optics—the world’s best electron-beam nanowriting facility—to fabricate the first uniformly redundant nanoarrays. The array was a 71 × 73 grid of 44-nm-square gold elements on a silicon nitride membrane.

The 2.3-nm-wavelength ALS beam was passed simultaneously through a target and one of the nanoarrays mounted on the same plate, providing a bright reference source. The image, projected onto a CCD, contains all the spatial information in three dimensions to reconstruct an image of the target.

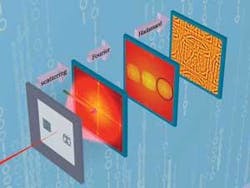

The scattered image was deconvolved much as a standard Fourier-transform holographic image—by simple Fourier transformation of the intensity—to yield an autocorrelation. But the intensity map in this case also includes a convolution of the object and the array, which must be subtracted using what is known as a Hadamard transform (see figure).

The result is a methodology that retains the resolution of x-ray holography (in this case, 50 nm) but with a jump of more than three orders of magnitude in efficiency. “The reconstruction was fairly straightforward,” says Marchesini. “In the end I was surprised to see how well it worked, even with the imperfections of the nanoarray.”

And what of biological samples? “In order to image a biological cell at 10 nm, the cell has to sustain the radiation equivalent to being one meter away from the Hiroshima bomb,” Marchesini says. “The only option to reach ultrahigh resolution seems to be to image the object before it blows apart.”

To that end, the team took their arrays to the Free-electron Laser in Hamburg (FLASH) facility at the DESY research center in Hamburg, Germany. There, the 13.5 nm wavelength FLASH beam illuminated a 17 × 19 array of 150 nm pinholes that shared a substrate with a spiroplasma bacterium. The 15 fs pulse—containing just 1012 photons—allowed imaging of the bacterium before vaporizing it.

The method’s resolution is limited only by the scale of the pinholes in the arrays, and the authors note that existing lithographic fabrication techniques with 15 nm resolution and 2 nm accuracy mean that straightforward improvements are just around the corner.

The team is excited to take its approach to new light sources, such as the Linear Coherent Light Source at Stanford University (Palo Alto, CA), as they come online. Meanwhile, the researchers are developing three-dimensional holotomographic imaging, as well as working to improve their facilities at the ALS with a dedicated beamline for coherent x-ray imaging.

REFERENCE

- S. Marchesini, et al., Nature Photonics, doi: 10.1038/nphoton.2008.154 (2008).