After years of sampling successive generations of light-emitting diodes (LEDs), Ron and Bernadette Olson finally converted the display holography process at Laser Reflections (San Francisco, CA) from halogen to LED spotlight illumination late last year, after encountering a new LED spotlight produced by OptiLED (Irvine, CA) on display at the Lighting Dimension International Convention (Oct. 18 and 19, 2002; Las Vegas, NV).

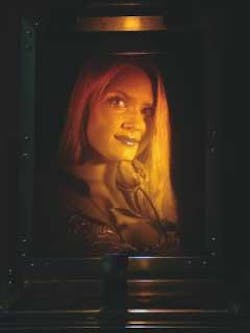

"First and foremost to our brand of display holography, much of which involves portraits, the single LED produces a crisper, clearer image resulting from the small emitter size and the relatively narrow spectral output," Ron Olson said. The single small emitter approximates a point source and optimizes depth of field, while the narrow band of wavelengths emitted by the LED source results in reduced scatter in the holographic film and higher contrast in the display (see figure).

In addition to aesthetic considerations, Olson also listed several performance advantages of the solid-state illumination: the power consumption is reduced from 750 to 30 W, the cost of the power supply drops from $500 to $20 and its size and heft is reduced from that of a bowling ball to a golf ball, and device lifetimes increase from 2,500 to 100,000 hours.

Although previous generations of LEDs showed promise, none had been packaged "into something that would transcend the highly overrated do-it-yourselfer market," Olson said. The 2-W solid-state devices that they started using last fall plug into standard track-lighting fixtures and offer blue (455 nm), green (530 nm), orange (590 nm), red (627 nm), and white beams with spreads that can be specified between 2° and 60° (4° is the standard, producing a 6-in.-diameter spot size at a distance of 6 ft). A nonimaging primary optic in series with a beam-shaping diffuser produces a uniform beam (the raw output of high-power LEDs tends to be strongly modulated in the midfield). Light-emitting-diode lamps that operate on 110-V power are available, but Laser Reflections currently uses an LED lamp that is a direct replacement for an MR 16 halogen bulb and that accepts direct-current voltages between 6 and 24 V.

The majority of work produced at Laser Reflections to date has been high-definition reflection holography, but the Olsons hope to extend the LED's combination of narrow linewidth, high brightness and directionality into abstract backlit panels up to 24 × 20 in., using available overhead fixtures. They believe that such displays will gain commercial acceptance anywhere a clear glass pane can be made more entertaining, such as restaurant booth dividers and storefront windows. They also plan to power such exhibits and window displays with a small rechargeable battery as the sole power source.

The solid-state illumination design produces virtually no stray light—important when displaying images in nightclubs, commercial lobbies, or retail point-of-purchase environments. As well, the LED produces almost no heat when compared to its halogen counterpart. This is important in designing fixtures that include integral lighting, and it relieves the liability concerns that plague white-hot halogen spotlights.

"In every spanking-new technology, there are a few 'advance-guard' applications that precede the killer apps to come," Olson said. "For the LED lighting market, this would include accent lighting and (lucky for us) holographic display."

About the Author

Hassaun A. Jones-Bey

Senior Editor and Freelance Writer

Hassaun A. Jones-Bey was a senior editor and then freelance writer for Laser Focus World.