Holographic data storage prepares for the real world

From the perspective of the daily computer user, the information age has turned into a seemingly endless cycle of generating, accumulating, accessing, and archiving electronic data. As a result, the ability to store this ever-growing body of data—critical or not—has become an increasing challenge. Conventional surface-storage techniques are rapidly reaching their physical limitations, opening the door for volumetric approaches such as optical holography that can store data in the range of 1 Tbit/cm3 on a single CD-sized disk and offer rapid access to that data via the Internet.

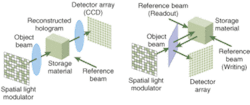

The concept of holographic data storage has been around since the late 1950s; the first published papers (1963) are attributed to Pieter van Heerden, a scientist at Polaroid who realized that three-dimensional holograms could store data at a volumetric density of 1 bit per cubic wavelength (see Fig. 1 and "How it works," [below]). While the technology's potential for data storage has been lauded off and on ever since, various technical issues have so far kept it confined primarily to the laboratory. But thanks to ongoing interest in next-generation storage that can handle the increasing glut of electronic data and the development of new photopolymer and photorefractive materials, holographic data storage is finally ready for the real world.

"The big corporations that have made DVDs—which have a storage capacity of less than 20 Gbytes—and BluRay (an optical video-recording format using a 405-nm blue-violet laser that enables the recording, rewriting, and playback of up to 27 Gbytes of data on a single-sided, single-layer 12-cm CD/DVD disk) happen have realized that after BluRay reaches 80 to 100 Gbytes, there is a gap in their storage capabilities," said Michael Ledzion, CEO of Polight (Cambridge, England), a spinoff of the University of Cambridge that is developing an inorganic glass material for holographic data storage. "Holographic data storage enables a big leap upward to the terabyte level, while the laws of physics will stop other technologies from going any further."

Because holography is a volumetric storage technique, it is well suited to "read-only" memory and content-protection applications. As a result, the first commercial storage devices are expected to be "WORMs"—write-once, read-many three-dimensional storage disks that function as standard interfaces to existing libraries and servers. These first products are expected in the next 18 to 24 months; Aprilis (Maynard, MA), for example, plans to release a holographic drive with a removable WORM 200-Gbyte capacity in disk form factor and at least 100 Mbyte/s data-transfer rate in 2005, according to chief technology officer David Waldman (see Fig. 2 and Laser Focus World, February 2003, p. 17). Similarly, InPhase (Longmont, CO) is developing two-chemistry photopolymer materials and drives for holographic storage and expects to have its first writable product on the market by 2005.

"What is pretty clear now is that holographic storage systems with interesting performance points can be engineered and built using write-once photopolymer media," said Geoffrey Burr, a member of the holographic data-storage team at IBM Almaden Research Center (San Jose, CA). "What is not yet clear is whether the cost of such systems will be attractive to potential customers, particularly those in the initial markets of interest, such as archival storage."

The real "holy grail" is fast-access read-write data storage using gated photorefractive materials. Researchers at IBM and elsewhere are exploring high-density, erasable holographic memory that could provide submillisecond access to stationary blocks of media for potentially large consumer applications such as video-on-demand, on-line archiving, and Web-based data mining (see Fig. 3). Holographic techniques have demonstrated the ability to transfer 1 Gbits/s (60 times faster than DVDs), but so far such applications remain in the R&D phase. According to Waldman, the most impressive data-rate display to date was carried out by the Holographic Data Storage System consortium under the direction of Lambertus Hesselink, professor of electrical engineering and applied physics at Stanford University. In that demonstration, which used a single optical head and rotating Aprilis disk media, 12 simultaneous movies were recorded and read back for a cumulative data rate of 1 GBit/s.

"We haven't found the ideal material for read/write holographic data storage," Burr said. "We have looked at both photopolymers and photorefractives such as lithium niobate and, in general, the systems that have interested us the most (read-write, fast-access ones, as well as content-addressable) are those that require read-write media such as lithium niobate. What these systems lack is a truly gated read-write material that is transparent to the readout light except in the presence of a gating beam of another color. And no one knows whether such materials are even possible, which may be why the startups we know about have used, at least to date, write-once photopolymer media instead."

Application-specific materials

Even so, those startups are confident that their holographic storage media and techniques will be ready for read/write applications about the time their customers, and end users, really need them. "The mainstream optical community seems to believe that holography is what will follow BluRay," said Bill Wilson, chief scientist at InPhase. "I think this is a fairly new turn that has happened over the past year as everyone searches for the follow-on to blue DVD."

One reason for this optimism is that, for the most part, the fundamental media issues that have so far impeded the commercialization of holographic data storage have been resolved. With most of the companies in this field currently focused primarily on media and materials development, holographic materials have undergone rapid development in recent years, resulting in more-robust photorefractive and photopolymer media and major performance improvements.

At Aprilis, for example, scientists have worked to develop a method for recording in photopolymerizable materials called cationic ring opening polymerization (CROP). According to Waldman, Aprilis's polymer is an epoxy-modified siloxy silane that undergoes minimal volume change during recording, yielding an ability to use substantially thinner recording material and still achieve high capacity.

"Aprilis CROP media is the only holographic recording material in the world that has shown it can be used for recording data-page holograms in real time while the material is spinning, a necessary condition for a high-performance drive that provides for recording information," he said. Aprilis is currently selling its holographic recording media to development groups at more than 15 companies worldwide and owns 53 pending and issued patents.

InPhase boasts a "two-chemistry" polymer-based approach that, according to Wilson, makes it possible to customize the material for each application. Founded in December 2000 as a spinoff of Bell Labs, InPhase has more than 40 patents related to holographic data storage, currently sells its media to more than a dozen customers, and has a two-year, $2 million Advanced Technology Program grant from the National Institute of Standards and Technology to develop and demonstrate rewritable recording materials for holographic data-storage systems with ultrahigh storage density and data access rates.

"Our strategy for developing media is different from our competitors," Wilson said. "The typical photopolymer holographic recording media have two parts: the matrix material and the photo material, which are very similar. The problem is that all the parameters end up being coupled. So our strategy was to create a set of design rules that allows development of two independent but compatible polymers with very high clarity. By compartmentalizing the materials this way, you can dial the material [properties] for each application. You want to be able to optimize one parameter without messing up another one."

Polight sets itself apart from the competition with an inorganic glass-based material, Holonide. According to Ledzion, Holonide's patent-pending formula gives it extremely high optical quality. In addition, like Aprilis' CROP material, which can be sensitized to all forms of actinic radiation from 700 (red) to 405 (violet) nm, Holonide is sensitive to green and red lasers, enabling the use of low-cost manufacturing processes originally developed for DVD disk production.

Optimizing the components

With most of the fundamental materials issues resolved, attention is now turning to the need for application-specific optical components that will improve system performance and storage capabilities. While the availability of low-cost "plug-and-play" components such as liquid-crystal displays for spatial-light modulators (SLMs) and CCD camera chips for detector arrays has facilitated the development of holographic drives, these devices were originally developed for display and vision applications, not storage. Thus, for holographic storage to realize its true potential, advances in lasers, SLMs, and detectors are needed.

"It is true that none of the parts need to be invented, but some could be optimized for this application," Wilson said. "Our assumption is that after the first generation of drives gets out there, people will begin to build components specifically for storage."

Efforts are already under way to improve the performance and bring down the cost of the lasers. Currently, the type of laser (most commonly red diode or green diode pumped solid-state) and wavelength are determined by the end product and its storage-density requirements, but most researchers see short-wavelength blue lasers as the ultimate laser for holographic storage because of the ability to dramatically increase storage volume. According to Ledzion, all of the work currently taking place in blue-laser development will result in the price of this technology dropping drastically in the next three to five years, while output powers increase (ideally to 30 to 50 mW).

"High-performance holographic data storage requires high-power, single-spatial-mode lasers. Recording holograms onto a moving substrate requires a pulsed laser with high pulse energy," Burr said. "A particular game-changer for holographic storage would be the development of a rapidly (<1 ms) and widely tunable (>200 nm) visible-light laser."For content-addressable holographic storage, potential system performance increases steadily with faster SLMs that are capable of precise phase and amplitude control, he added. "Such SLMs would also be helpful for ordinary address-based holographic storage, but currently available SLMs may already work well enough for that application."

In the long run, Wilson says, sustained interaction between system, component, and materials developers will continue to be critical as holographic data storage moves into the commercial realm. Some of the first markets will likely be smaller, high-level niches that require write-once-type applications, such as government, insurance, medical imaging, and the film industry. In fact, Ledzion believes that write-once business applications could prove to be a significant market for holographic data storage, with new legislation being enacted in Europe and North America requiring that every e-mail be logged and archived before it is sent.

"The way we should think of holographic technology for data storage is that it is just a toolbox of strategies for storing information holographically that will allow you to get more performance out of an optical drive," Wilson said.

How it works

Holographic technology stores pages of information as optical interference patterns that form when two coherent laser beams intersect within a thick, photosensitive optical material. The object beam contains data that has been imprinted by a spatial-light modulator (SLM). Through chemical and physical changes in the photosensitive medium, a replica of the interference pattern is stored as a change in the absorption, refractive index, or thickness of the photosensitive medium.

To retrieve data, the object beam must pass through a high-quality imaging system. For high density, the imaging system must have a short focal length to allow tight focusing of the large SLM pixel array at the storage media. Optical aberrations, diffraction from the aperture used to limit the volume of media exposed, magnification error between the SLM and detector, and misfocus or misregistration of the detector array can spread energy from one pixel to its neighbors, producing errors in the retrieved data.

Once the optical system is configured to pass the SLM data to the detector array, the next step is to provide independent recording and retrieval of each hologram. By diffracting the reference beam off the recorded optical interference pattern, the data page is regenerated and captured by an array detector, which allows the data to be reconstructed. This parallel recording and readout of 1 Mbit at a time enables the rapid data-transfer rates of holographic storage.