Mature PMT technology offers sensitivity for emerging needs

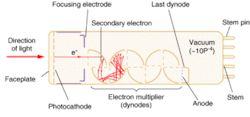

Despite their age, photomultiplier tubes (PMTs) are still preferred when low-light-level detection is required. Over the years, the development of PMTs has yielded better sensitivity, faster response time, smaller package size, and more spectral-response choices, but the basic elements of the PMT have largely remained unchanged. The structure of a PMT can be simplified into three basic components: the photocathode, the electron multiplier, and the anode (see Fig. 1).

The photocathode is responsible for the conversion of photons into electrons. Photocathode performance is measured using the quantum efficiency (QE), which is the percentage of photons that are converted into electrons at a given wavelength. Photocathode materials are chosen depending on the wavelength to be detected. Common materials are bialkali, multialkali, and silver oxygen cesium (Ag-O-Cs). Generally, the long-wavelength cutoff is determined by the photocathode, while the window material determines the short-wavelength cutoff.

New materials and capabilities

Recently, new photocathode materials have been developed to address specific needs. Among them is the gallium arsenide phosphide (GaAsP) photocathode, which has 50% QE at 550 nm. This PMT has very high sensitivity in the visible region. The gallium arsenide (GaAs) photocathode has wide spectral response, with a QE of 12% at 800 nm, helping to make this PMT well suited for very low-level measurement in the near-infrared (NIR).

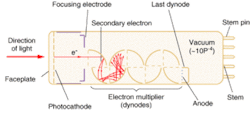

Indium/indium gallium arsenide phosphide (In/InGaAsP) and indium/indium gallium arsenide (In/InGaAs) are very specialized detectors for low-light-level detection at wavelengths above 1 µm. These detectors boast 1% QE at 1.3 and 1.5 µm, respectively. Radiant sensitivity (S), the electrical current generated per watt of incident optical power (A/W), is commonly used to describe the spectral response of a detector, allowing the user to easily convert signal output to input light power. The QE can be quickly calculated from these spectral response plots by using the following equation:

null

The next component in the PMT is the electron multiplier. An electron generated by the photocathode is accelerated and guided toward the first dynode by an electrical field produced by the focusing electrodes. The probability that these electrons land in the first dynode is called the collection efficiency. The accelerated electron hits the first dynode and produces secondary electron emissions. These secondary electrons are then accelerated towards the next dynode. This process is repeated on the following dynodes, allowing the PMT to achieve high gain.

To produce the electric field, a high voltage is required. Typically, the photocathode is given a negative high-voltage potential; for example, –1000 V. The voltage potential is gradually increased by a voltage divider until it reaches ground potential at the anode. The electrons are then accelerated toward the positive potential. This method is convenient, because it allows both AC and DC measurements to be conducted.

The most common method used for a voltage divider is the resistive string. In this case, resistors are connected in series between the dynodes, allowing for the progressive step of voltage along the electron path. The values of these resistors are selected to match the ratio recommended by the manufacturer of the PMT.

A variety of dynode types are available to suit every application. The most common are circular cage, box and grid, linear focused, and metal channel. The circular cage type is compact and has fast response time. It is used in all side-on PMTs and some head-on PMTs. Despite being slow, the box and grid type is typically used because of its superior collection efficiency, allowing the detectors to have high detection efficiency and good uniformity. The main features of the linear focused dynode are fast time response, good time resolution, and excellent pulse linearity. The newest design of the group, the metal-channel dynode, is used in metal-package PMTs and offers a very compact size, high-speed response, and also allows multichannel and position-sensitive outputs.

The gain of the electron multiplier stage is dependent on the high voltage applied to the PMT. It is important to note that the gain of the PMT does not have an impact on the signal-to-noise ratio (S/N) of the measurement. Because the gain contributes equally to the signal and noise, it cancels in the S/N calculation. The main purpose of the PMT gain is to amplify the photocathode current to a level above the readout circuitry noise. Once the anode current is high enough that the circuitry noise can be ignored, the dominant factors in S/N are input light power, QE, and bandwidth.

Time-response characteristic

The time-response characteristic of the PMT is dependent on the electron multiplier stage. The dynode structure and applied voltage are the main contributors. There are three main specifications related to the response time of PMTs: rise time, electron transit time, and TTS (transit time spread). Rise time is defined as the period it takes for the anode output to rise from 10% to 90% of the peak amplitude when the whole photocathode is illuminated by a delta-function light pulse. The electron transit time is the time lapse between the light hitting the photocathode and the anode outputting a signal. Transit time spread is the fluctuation of the electron transit time between individual light pulses.

The last element of the PMT is the anode, which is where the signal readout takes place. The two most common techniques for reading the output of a PMT are analog and photon counting. The output of the PMT is a current, therefore it needs to be converted to voltage before it can be read by most measurement equipment. One way to accomplish this is by connecting a load resistance across the anode and ground. The drawback is that the value for this load resistance affects the linearity and frequency response of the PMT. Using a load resistance of 50 W will avoid losing linearity range and frequency response. A low load resistance will generate low voltage. This voltage will be small enough that the potential difference between the anode and the last dynode would remain high.

In analog measurement, a transimpedance amplifier (TIA) converts the current to voltage, as well as providing additional gain and limiting the bandwidth. The TIA will convert anode currents in the ranges of nanoamps and microamps to voltages in the millivolt and volt ranges, respectively, which are easily measured by voltmeters and analog-to-digital devices. A major contributor in the signal-to-noise calculation is the shot noise of the signal. This is directly proportional to the bandwidth, so limiting the bandwidth reduces the shot noise and increases the S/N ratio.

When the signal level is so low that the analog method doesn't provide enough S/N ratio, then photon counting is preferable. This method uses a high-speed amplifier to convert the output into a voltage pulse, and then a discriminator eliminates low-amplitude pulses. The high-amplitude pulses go through a pulse shaper that outputs a transistor-transistor-logic (TTL) pulse for each of these pulses.

Because most of the noise pulses after the amplifier have low amplitude compared to the signal pulses, a discriminator discards low-amplitude pulses, while most of the signal pulses are allowed to pass. Hence, a PMT with high gain is recommended for photon counting. In a PMT with high gain, the signal pulses will have greater amplitude compared to the noise pulses, making it easier to find the optimum discriminator level for best S/N.

Homeland-security applications

The increase in international terrorism has created a market for products designed to increase security. Photomultipliers are widely used in these products, which include cargo-inspection systems, as well as radioactive-material and biological-threat detectors.

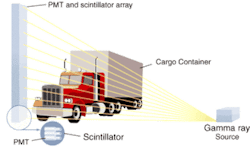

Cargo-inspection systems are typically constructed with a radiation source that could be x-ray or gamma, as well as an array of PMTs fitted with scintillators (see Fig. 2). There are many scintillators on the market that convert radiation into light that can then be detected by PMTs. The detector array creates images of the container contents by measuring the absorption of the materials.

Because this method can only detect absorption, a thick sheet of aluminum will look the same as a thin sheet of lead. The lack of density information makes it difficult to detect organic compounds often used to make explosives. For luggage inspection, a new technology allows the approximation of density, making it easier to pinpoint organic materials such as plastic explosives. This method detects the x-rays that scatter back from the organic materials. The backscatter only occurs with organic materials, allowing the system to detect plastic explosives or weapons hidden inside metal enclosures.

The use of PMTs in the detection of radioactive materials is also significant. There are a variety of systems on the market, ranging from handheld devices to portal monitors used to inspect containers. Current systems can detect gamma rays and neutrons. The more common systems detect gamma rays, because these are easy to detect with a PMT and a scintillator. More-advanced products detect neutrons instead.

The advantages of detecting neutrons over gamma rays are quite important. Unlike gamma-ray sources, there is no legitimate reason to possess a neutron source. Another advantage is that the neutrons are very hard to shield, and the neutron background is small and constant. All these features contribute to a low false-alarm rate. Recently, fiber scintillators capable of detecting neutrons have been paired to PMTs, allowing a very sensitive and reliable detection system to be used in portal monitors for applications in which large quantities of people and cargo are inspected.

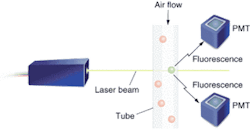

Another important use of PMTs in this context is real-time detection of biological threats in the air. The system takes air from the atmosphere and passes it through a laser beam. A PMT will detect any fluorescence in the blue and UV region (see Fig. 3). The presence of fluorescence means that biological molecules are present. The system is designed to detect the presence of biological material so the area can be evacuated. After the evacuation, more time-consuming tests can be done to identify the specific type of biological agent present.

GUSTAVO ASENCIOS is an applications engineer at Hamamatsu, 360 Foothill Rd., P.O. Box 6910, Bridgewater, NJ 08807; e-mail: [email protected].