Terahertz pulses create diffraction-limited images

Laser pulses each lasting hundreds of femtoseconds are being used to generate, detect, and measure picosecond far-infrared terahertz pulses in materials to produce images of internal structure and composition. As described in CLEO `95 paper CPD44, researchers Bin Bin Hu and Martin Nuss of AT&T Bell Laboratories (Holmdel, NJ) Advanced Photonics Research Department transmit terahertz transients through various objects, then use an imaging and detector system of lenses and mirrors to focus the signals, analyze the changes in them as they pass through objects, and convert the data into image form.

Imaging is possible because of the highly specific frequency-dependent absorption in the terahertz range by many materials, particularly when in the gaseous state. Materials with high electrical conductivity, such as metals, are opaque to terahertz pulses, whereas plastics are transparent. These material properties, coupled with the ability to focus the terahertz transients to the diffraction limit, permit using terahertz beams for imaging applications in which spectral information, and thus chemical composition, on an object can be acquired at every pixel viewed.

This type of infrared imaging does not require cooled detectors and can be built into compact systems compatible with integrated-circuit technology. Potential applications include tissue imaging, chemical-reaction analysis, environmental monitoring, and materials and package inspection. With signal-processing refinements using speech-recognition-based architectures, chemical composition mapping of objects in real time should be possible.

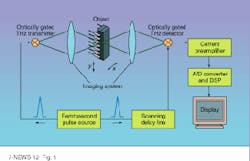

The imaging system consists of a self-modelocked Ti:sapphire laser, an optically gated terahertz transmitter whose spectrum ranges from dc to terahertz, imaging optics, a gated terahertz detector and fast-scanning delay line, preamplifier, analog/digital converter with a digital-signal-processing (DSP) chip, and an image display (see Fig. 1). The object being imaged typically emits a single cycle of radiation centered at 1 THz after being illuminated by a 100-fs pulse from the laser operating around 800 nm.

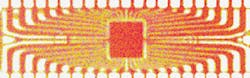

The scanning delay line downconverts the terahertz transients into the kilohertz range for real-time acquisition and processing—the ratio of the speed of the delay line to the speed of light gives the downconversion rate, so a 0.3-cm/s delay-line speed converts 1 THz to 1 kHz exactly. Because of the brightness of the terahertz transients, signal-to-noise ratios exceed 100:1 after the preamplifier. The DSP chip processes the time domain signal and extracts the spectral data.A use for terahertz imaging is inspecting the internal structure of a semiconductor integrated-circuit chip (see Fig. 2). The terahertz-generated image clearly shows the chip as well as the metal contacts and their integrity inside the plastic packaging. Spatial image resolution is roughly 300 µm--the diffraction limit of radiation with 1-THz center frequency. Higher resolution can be obtained by selectively processing data only at higher frequencies.

David Miller, head of the advanced photonics department at Bell Laboratories, notes, "This research is significant because, although terahertz time-domain spectroscopy has been done experimentally in the past, it has never been used in an imaging system."

About the Author

Rick DeMeis

Associate Editor, Technology

Rick DeMeis was Associate Editor, Technology for Laser Focus World from March 1995 through March 1997.