Dual-use technologies enhance commercial IR cameras

Dual-use technologies enhance commercial IR cameras

By re-engineering military technologies for packaging of cryogenic components and infrared detectors,

commercial camera manufacturers can offer

technically advanced products.

Joseph R. McCoy

Recent trends in commercial cryogenic packaging and "off-the-shelf" second-generation array availability have complemented the rapid development of the two-dimensional

(2-D) matrix, infrared (IR) array camera market. Decade-old military technologies fortified with recent reliability enhancements are truly achieving a "dual-use" status in this most competitive market place. Thermal-imaging-camera manufacturers such as Amber (Goleta, CA), Cincinnati Electronics (Mason, OH), FLIR Systems (Beaverton, OR), Inframetrics, (Billerica, MA), Rockwell International (Thousand Oaks, CA), Santa Barbara Focal Plane (Santa Barbara, CA), and others all tout 2-D array cameras that are considered state of the art. Noteworthy is the fact that some of these cameras are being evaluated by various military organizations for limited-use applications under the commercial off-the-shelf thrust.

The commercial IR camera market includes applications such as surveillance, process monitoring, noncontact temperature measurement, medical imaging, and a host of scientific research areas. The cornerstone for these cameras, as in any IR system, is the detector. Thermal imaging cameras use detectors arranged in a 2-D matrix; common materials include indium antimonide (InSb), mercury cadmium telluride (MgCdTe or MCT), or platinum silicide (PtSi). To date, the majority of IR cameras sold in the USA have 2-D array formats of either 256 detector elements (pixels) by 256 pixels or 320 by 240 pixels.

The technologies for fabricating these devices stem from government-funded programs for the military; subsequent build-to-order military contracts have put versions of these detector arrays on platforms ranging from B-52 bombers to surface-to-air missiles. In 1989, some industry analysts saw the commercial industry using the "cull" arrays from military programs and/or procuring sufficient volume from the military suppliers to help reduce the cost for the military. This scenario has yet to occur.

Driven by the laws of supply and demand that govern the commercial arena, present suppliers of 2-D IR arrays to thermal-imaging-camera manufacturers are not the classic volume suppliers for military systems. These arrays are generally fabricated

specifically for commercial use and manufactured to "inventory" rather than contract. The Kodak KIR-0330S is an example of a catalog IR image sensor delivered from inventory (see Fig. 1). This trend has been paced by the customer demand to shorten the delivery time; it is now possible to procure a standard camera off-the-shelf from several suppliers.

Cooling packages

These IR arrays must be packaged with a cryogenic cooler to achieve the required environment for operation. Standard packaging and multiple suppliers of cryogenic coolers have complemented the evolution of off-the-shelf IR cameras in much the same way that the array availability has done. The cooler of choice is the small twin opposed piston linear compressor variety. This is generally favored over rotary coolers because of device lifetime. It is not uncommon to find a mean-time-to-failure (MTTF) in excess of 4000 hours associated with a linear cooler. It is important to note that a small rotary cooler, such as the one offered in the Inframetrics camera, has a lower power consumption, making it attractive for certain battery-powered applications.

Except for some small quantities, cooler suppliers generally do not build to inventory but can respond in a reasonable amount of time given an order. Packaging or integration houses such as Infrared Components Corp. (ICC, Utica, NY) often inventory a variety of coolers for use in their cryogenic packages to provide a rapid response to industry requests. Cooler-development programs targeted at improving MTTF continue to be funded by the US government, and some private companies are investing in development of these devices as well. Though the form factor of the proposed coolers may limit their application, equivalent costs and the projected MTTF of 50,000 hours will guarantee that every effort will be made to incorporate such a cooler into a majority of the commercial cameras.

The Dewar package, which integrates the array and the cooler so that optimal performance and efficiency can be obtained, has acheived some degree of standardization. Most cameras incorporate the integrated Dewar assembly that is the Dewar technology base for the next-generation military IR modules soon to begin limited production. Commercial offerings such as the ICC Type II Dewar product are designed to accommodate a variety of array types within a given format size (see Fig. 2).

The ICC manufacturing line achieves

true "flexible manufacturing" goals by providing for simultaneous manufacture and low level test of a line of products, incorporating InSb, MCT, or PtSi detector arrays, with little or no set-up change or schedule delay. Such manufacturing approaches are key to providing a low-cost, quality product to the industry via maintenance of the economies of scale. The US government is funding military suppliers to aid in the transition to a flexible manufacturing operation, in hopes of reducing costs in production for the military.

Common interfaces

The commercial suppliers have successfully established common interfaces for coolers, Dewars, and array mounting. Products using these interfaces are being produced at peak rates that approach 100 units per month at my company alone. Most new companies entering the IR camera market use these proven interfaces to avoid engineering charges; they would rather use the funds to develop system features to distinguish their product from their competitors` products.

A more recent trend is for the component suppliers to offer a complete package, inclusive of the Dewar, cooler, array, and some electronics. This has been coined an "infrared engine" by the industry and is intended to further simplify the component-interface issues for the system houses (see photo on cover and p. 67). Two final facts that cannot be ignored challenge thermal-imaging-camera manufacturers: the price of larger format arrays (640 ¥ 480 pixels) is decreasing to an affordable level, and "uncooled" 2-D arrays are looming on the horizon. Both will be trendsetting.

The commercial industry has established informal standards for cooled IR array packages that contribute to the low system cost needed to penetrate the market. Leading technologies and methodologies have been incorporated at the component levels, resulting in cameras that represent the best technology re-engineered for commercial applications. n

The Kodak KIR-0330S platinum silicide infrared image sensor, as integrated into an ICC Type II Dewar with a custom cold shield on a long-life 1-W linear cooler, can be used for both commercial and military applications.

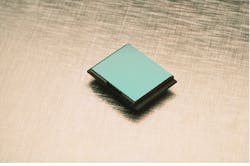

FIGURE 1. Commercially available two-dimensional detector array chips, such as the Kodak KIR-0330S, offer thermal-imaging-camera manufacturers detectors from inventory, rather than from a special production run.

FIGURE 2. Various array types can be accommodated in a Type II Dewar package. Dewar vacuum vessel with silicon window covering the array (left) and black-sheath-housed miniature twin piston compressor (right) make u¥the entire package.

JOSEPH R. MCCOY is president and CEO, Infrared Components Corp., 811 Court Street, Utica, NY 13502.