How to capture low-light-level images without intensifiers

GEORGE M. WILLIAMS and MORLEY M. BLOUKE

The low-contrast, hazy, green images from the Persian Gulf War, and more recently from Somalia, illustrate the performance limitations of conventional low-light-level television (LLLTV) imaging systems. A vast majority of imagers for low-light-level applications such as surveillance, microscopy, and spectroscopy use image intensifiers coupled to charge-coupled devices (CCDs). These systems suffer from degradation of signal-to-noise ratio (S/N), contrast, and resolution inherent in the gain mechanism of the image intensifier. For many low-light-level surveillance applications silicon intensified target (SIT) imagers are still used despite their "blooming" and unstable imaging characteristics. Because intensified CCD (ICCD) imagers do not have the resolution and sensitivity necessary for a majority of surveillance applications, users are left with few replacement alternatives as the installed base of SIT tubes ages.

New sensors based on thinned, back-illuminated CCDs allow for high-performance low-light-level imaging. Rather than relying on gain, a thinned, back-illuminated CCD (BCCD) increases the responsivity, fill-factor, contrast, and modulation transfer function (MTF) of the imager to improve the S/N of the resulting image—especially at high spatial frequencies. A BCCD device allows for superior resolution and contrast at moderately low light levels. With the combination of high MTF and high sensitivity, a BCCD video sensor provides imaging of scenes that cannot be achieved with conventional CCDs and for which ICCDs suffer from low contrast and resolution. The BCCD provides a solution for those users who require performance 10 to 40 times higher than a CCD, but cannot tolerate the contrast degradation and limited intrascene dynamic range of ICCD sensors (see "Drawbacks of conventional low-light-level imagers").

As the scene light level decreases to the point at which the number of photons available to each pixel are not sufficient to overcome the noise floor of the system, the BCCD can be placed in a vacuum photodiode and can be run in the "electron-bombarded" or EBCCD mode. The resulting imagery is superior to that of image intensifier tubes. Rather than providing the low-contrast, out-of-focus images that users of image-intensified systems have become accustomed to, the EBCCD offers sharp-contrast, low-light-level images (see photo above). This performance is achieved by offering nearly noiseless gain (gain of greater than several thousand is possible). Moreover, because the EBCCD has better MTF, it can also function effectively at high light levels; the combination of higher signal-to-noise performance over a larger spatial frequency range allows the imager to convey more scene information to the user.

Thinned, back-illuminated CCDs

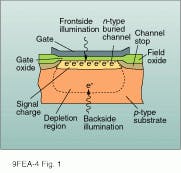

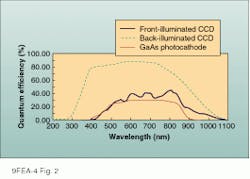

Thinned, back-illuminated CCDs (BCCDs) overcome the performance limits of the conventional front-illuminated CCD by illuminating and collecting charge through the back surface—away from the polysilicon electrodes (see Fig. 1). When the CCD is mounted face down on a substrate and the bulk silicon is removed, only a thin layer of silicon containing the circuit`s device structures remains. By illuminating the CCD in this manner, quantum efficiencies greater than 90% can be achieved.Thinning and back-illuminating the CCD also improves its ultraviolet sensitivity. The polysilicon gate electrodes of the front-illuminated CCD absorb almost all of any incident ultraviolet radiation. With appropriate antireflection coating, back illumination allows for up to 50% quantum efficiency at 200 nm. Ultraviolet performance is important for a number of applications including spectroscopy, fluorescence imaging, and missile warning systems.

Recent advantages in CCD design and semiconductor processing have resulted in CCD readout amplifiers with noise levels of fewer than 15 electrons per pixel at video rates. Several manufacturers have reported such low-noise performance with high-definition video amplifiers operating in excess of 35 MHz. The 90% quantum efficiency of a BCCD in combination with low-noise amplifiers provides noise-equivalent sensitivities of approximately 40 photons per pixel—10-4 lux—without any intensification. This low-noise performance will not suffer the contrast degradation commonly associated with an image intensifier.

Despite the high sensitivity and low noise of the BCCD, when sensitivity below 10-4 lux is required, a gain stage is necessary to overcome the noise threshold of the CCD imager. The most common method of achieving gain to date has relied on the use of an image intensifier.

Electron-bombarded imager

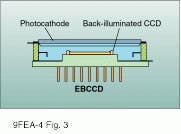

By integrating the CCD directly into the vacuum of the image tube, an EBCCD imager eliminates the complicated image-transfer chain of conventional ICCDs. A back-illuminated CCD forms the anode of the EBCCD sensor, eliminating the need for a microchannel plate, a phosphor screen, and a fiberoptic coupler (see Fig. 3). The photoelectrons emitted from the EBCCD photocathode are "proximity-focused" directly onto the electron-sensitive CCD.After photoelectrons enter through the back surface of the CCD, the silicon dissipates the incident photoelectron energy as electron-hole pairs, and electron-bombarded semiconductor (EBS) gain occurs. The EBS process is significantly lower in noise than the electron gain obtained using a microchannel plate. It is "ideal" in that it introduces negligible noise and can provide gain in excess of 3000—much more than is required to overcome the system noise floor.

By imaging the electrons from the photocathode directly with the CCD, the EBCCD avoids the inefficient and image-degrading process of converting visible light into electrons at the photocathode, back into light at the phosphor screen and then back into electrons in the CCD. Because of the reduction in the number of image conversions and the significantly greater signal-to-noise performance, an EBCCD has higher contrast and resolution than an ICCD. The EBCCD sensor is also much lighter and more compact than an ICCD sensor, and having no fiberoptic interface, it is more reliable. These characteristics make the EBCCD a good candidate for military, helmet-mounted night-vision systems as well as for covert surveillance applications.

Comparing sensor performance

The fundamental concepts of image evaluation were established for film-based systems in the 1940s. In the 1970s, the introduction of discrete-element detector arrays and the advent of digital computers capable of performing complex Fourier computations improved upon these concepts and popularized the field of digital image processing. Despite the widespread use of CCDs and of digital signal processing, knowledge of the underlying factors contributing to image quality for low-light-level CCD-based systems is lacking. Terms such as MTF, CTF, limiting resolution, minimum resolvable target, and contrast, indispensable for system implementation and signal analysis, are often misused to describe LLLTV image system quality, and their relations are little understood. As such, no standard exists for characterizing low-light-level CCD-based imaging systems.

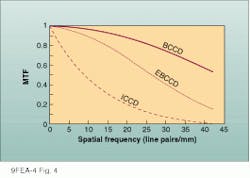

The detection capability of a LLLTV imager is proportional to its MTF characteristics, its responsivity, its gain, and its noise performance. A low-light imaging system must optimize all of these factors and cannot maximize one at the expense of another. The modulation transfer function of the sensor is a physical property of the information link between the scene and the observer. Unlike image-intensified systems that obtain high-resolution information at the expense of gray-level information, the EBCCD and the BCCD have high contrast as well as high resolution.

When plotting MTF, it is useful to think of the area under the curve as a measure of how "fuzzy" and "out of focus" an image will appear (see Fig. 4). The less area under the curve, the less sharp an image will appear. As the total area under the MTF curve for the EBCCD is 100% greater than the ICCD, the EBCCD will have more information in its images. Over the dynamic range from 10-7 to 10-2 lux, the BCCD provides greater information than either the EBCCD or the ICCD, however, because of its high resolution and S/N at moderate light levels.At low light levels, it is the combination of both S/N and MTF that determines the sensor`s ability to image a target of a given spatial frequency and illumination. The BCCD achieves low-light-level performance by offering high sensitivity and improved MTF characteristics, without resorting to a gain stage. In comparison, low MTF and S/N minimize the effectiveness of the ICCD. Over the dynamic range from 10-6 to 10-2 lux, the BCCD provides twice the amount of information of the ICCD and images high-spatial-frequency targets at lower light levels than does the ICCD. However, as the BCCD does not have the ability to image much below 10-4 lux, the EBCCD provides more information from these low light levels than either the BCCD or ICCD. The high MTF values for the EBCCD in combination with its noiseless gain allow it to achieve high-resolution images under all light levels.

A new class of video-rate imagers based on thinned, back-illuminated CCDs is available to replace conventional image intensifiers. The BCCDs and EBCCDs have better low-light-level performance than image-intensified approaches. These new devices provide high-contrast, high-resolution low-light-level imaging and should benefit scientific research as well as make nighttime flights safer for aviators.