Optical storage lights the multimedia future

One of the great problems of the Information Age is how best to store the glut of images, sounds, data, and words that assault our senses every day. It is an age-old problem for librarians, but one that we all must confront today as the world becomes more interconnected and complex. Since at least the time of the Sumerians (circa 3000 BC), information has been preserved by symbols scrawled on tablets, papyrus, and paper. But during the 19th century, new information technologies began to emerge that demanded radically different methods of storage. For example, cameras, motion pictures, phonographs, and electronic computers store their information on photographic film, phonograph records, and magnetic tape.

These three recording media illustrate the three basic forms of information storage: optical, mechanical, and electromagnetic. This article focuses exclusively on the two most advanced methods of optical storage—optical disks and holograms.

Reading optical disks

Anyone who has listened to music from an audio compact-disk (CD) player, watched a movie on video disk, or worked on the latest multimedia desktop computer can appreciate the revolutionary impact of CDs. But the most obvious enhancements of CDs over older storage technology—fast random access and signal clarity—have more to do with their disk-like shape and digital encoding than anything else. The real advantage of CDs stems from the optical storage and retrieval technique and the low-cost, durable, plastic storage medium.

Unlike phonograph records, audio tape, video cassettes, floppy disks, or hard disks, where the signal pickup mechanism is in direct contact (or nearly so) with the storage medium, a CD spins approximately 1 mm above the optical head and never comes into contact with it. Information is stored on the underside of the disk in a digital form represented by pits of different lengths embedded in an aluminum-coated layer protected by a surface coating of plastic. The pits follow a helical path outward from the center, similar to the groove of a phonograph record. On a CD, however, the information-carrying pits ride on a flat-topped helical ridge separated by narrow grooves.

To read information off the spinning disk, CW light from a low-power (less than 3 mW) GaAlAs diode laser is tightly focused onto the pits by a short-focal-length objective mounted on a movable read head. Servo motors keep the laser beam focused on each pit by controlling both the up-and-down and side-to-side tracking of the read head as the disk spins above it. Light reflected from the ridge and pits recreates the modulated information signal as a serial stream of data bits. A photodetector then converts the modulated light reflections back into an electrical signal for digital decoding and amplification.

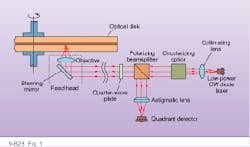

Although the process of reading a CD seems fairly simple in theory, it is, in practice, a marvel of electro-optic and optomechanical integration (see Fig. 1). First, the characteristic elliptical beam profile of the diode laser must be collimated and circularized, otherwise the objective cannot bring the beam to a sharp focus at the CD. Anamorphic optics are used to do this.Next, a polarizing beamsplitter and quarter-wave plate are used to separate the outgoing CW laser beam from its modulated return reflection. The purpose of the quarter-wave plate is to convert the linearly polarized laser beam passing straight through the beamsplitter into a circularly polarized beam. The circularly polarized light back-reflected from the CD is then reconverted by the same quarter-wave plate into linearly polarized light whose polarization plane is rotated 90° relative to the outgoing beam. This enables the beamsplitter to divert the back-reflected light toward the photodetector and also reduces feedback to the diode laser.

The read head itself is designed for minimal mass, because it must move quickly to correct tracking and focus errors. The objective also must have a high numerical aperture (NA) in order to minimize the focused spot diameter and the working distance. A typical objective is made of lightweight plastic and has a focal length of 3 to 5 mm, an NA of 0.5 to 0.6, and a diameter of approximately 4 mm.

The modulated return light carries the information signal, but it also can be used to monitor focus and tracking errors of the read head. To detect focus errors, the return light can be passed through an astigmatic lens before reaching the photodetector. Focus errors of the read head will then cause the beam shape on the photodetector to change asymmetrically. If a quadrant detector (four integrated photodetectors arranged in a contiguous quadrant pattern) is used as the photodetector, a change in beam shape will generate an error signal from the detector that can be fed back to the read-head servo motor to correct the focus.

The same quadrant detector can be used to detect and correct tracking errors by taking advantage of the phase difference between light reflected from a ridge and light reflected from a groove. If the laser beam is not centered on the ridge, interference between groove-reflected light and ridge-reflected light will skew the Gaussian intensity distribution one direction or the other at the detector, generating a tracking error signal for the read-head servo motors. The total response of all four elements of the detector defines the information signal.

Other designs for reading optical disks have been developed and continue to evolve. For example, many audio CDs use a three-beam method to generate the sound and tracking-error signals. This design positions a low-frequency sinusoidal diffraction grating between the circularizing optics and beamsplitter of Figure 1 in order to generate two closely spaced, diffracted tracking beams on either side of the bright central beam (see Laser Focus World, May 1995, p. 131). Separate detectors are used to sense the three reflected beams, the central one being used for the audio signal.

Recent advances in integrated optics make it possible to combine the laser, beamsplitter, objective, and photodetectors onto a single, miniaturized read head. The technology uses waveguide optics and holographic optical elements to focus the laser beam onto the CD and redirect the back-reflections into photodetectors for tracking and signal detection. These designs should further reduce the size and cost of CD players.

Writing and rewriting to CDs

While CDs have driven the venerable phonograph record into virtual extinction and may even replace video cassettes, their success would be limited if they could only be read from and not written to. To address this, developers have created a variety of optical-disk technologies that can be classified as either write-once or erasable. Both types require lasers with higher power than read-only systems, because the laser beam must physically alter the storage medium in order to write to it. Writing data to the disk also requires a modulated laser beam. However, the data stream is read with the laser running as a low-power CW light source, just as it is with conventional read-only CDs.

Write-once optical storage—commonly called write-once, read-many (WORM)—is designed for archival data storage applications, especially those that require an indelible trail, such as birth, medical, and insurance records. Consequently, WORM disks are constructed with permanence and storage capacity in mind.

One of the simplest and most successful WORM schemes uses a disk consisting of an absorptive layer of tellurium (Te) alloy sandwiched with an air gap between two protective sheets of glass or plastic. A laser writes information on the Te layer by literally burning holes in it. Storage capacity can exceed 10 gigabytes of digital data for a double-sided, 14-inch disk. Automated "jukeboxes" containing stacks of WORM disks can store terabytes of data. Other WORM-disk technologies use dye-impregnated polymer layers or layers that permanently change their phase when irradiated. And virtually all have storage lifetimes of 15 years or more.

Magneto-optical storage

But for erasable optical storage, the most important medium is the magneto-optic disk. This medium combines the erasability of magnetic storage with the relative permanence of optical storage and is commercially available in both 3.5- and 5.25-in. formats with storage capacities of 230 Mbytes and 1.3 Gbytes, respectively.

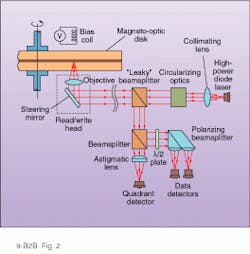

Magneto-optic systems store information by focusing an intense laser beam onto a disk layer coated with a ferromagnetic alloy such as TbFeCo or FeTbGd and locally heating it to the Curie temperature. At this point, the ferromagnetic material becomes paramagnetic, which means its internal magnetic polarity can be set by an external magnetic field. A tiny coil magnet mounted on the read/write head supplies this external field and defines each data bit by flipping the field polarity from north to south or vice versa. Each data bit becomes permanently stored on the disk when the laser power is removed and the material cools below the Curie point.

Reading from a magneto-optic disk is more complicated than from the read-only or WORM varieties because each data bit stored on the disk affects the polarization of the low-power read beam rather than its intensity. The process relies on the polar Kerr effect of the ferromagnetic layer, which rotates the polarization plane of the laser light reflecting off its surface. The amount of rotation is slight (less than 0.5°), and its direction depends on the magnetic-field orientation of the ferroelectric layer directly under the read beam. Conventional magneto-optic systems use a combination of polarizing beamsplitters and differential detection to acquire the data signal at an acceptable signal-to-noise ratio (see Fig. 2).As with WORM technology, dye-impregnated polymers and phase-change media also have been investigated for erasable optical storage, but the magneto-optic approach has achieved the most commercial success since its introduction in 1988. Of course, the success of any optical storage method depends on storage lifetime, hardware compatibility, data access speed, removability, convenience, and above all—storage capacity.

The areal storage capacity of optical disks is quite high. For example, a standard CD-ROM can store more than 500 Mbits of data per square inch. Various electronic and optical tricks can be played to maximize the storage capacity, but areal capacity ultimately depends on the laser wavelength which determines the minimum spot size on the disk.

For years GaAlAs lasers set the wavelength at 780 nm, because these were the first diode lasers to offer the reliability needed for commercial applications. But now industry standards are being prepared to accommodate 680-nm GaAlAsP lasers which should boost areal density to 1.1 Gbit/in.2, with the help of some elegant data-channel techniques. Moreover, laboratory research with 428-nm frequency-doubled diode lasers has achieved areal densities of 2.4 Gbit/in.2.

Finally, higher storage capacities also have been attained by using stacks of translucent storage layers on a single disk, which multiplies the storage capacity by the number of layers. Each layer is separately addressed by changing the focal position of the read head, and crosstalk between data stored on different layers is minimized by maximizing the NA of the read-head objective.

Holographic storage

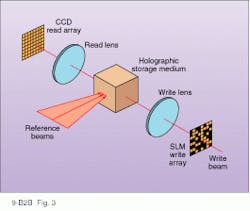

But beyond the already high storage capacities of optical disks lies the promise of holographic data storage. Although more than 30 years of research on holographic storage has yet to yield a single practical system, some researchers are now predicting that within the next ten years the entire Encyclopedia Britannica could be stored in a volume the size of a dime. Furthermore, data transfer rates of more than 1 Gbit/s and random-access times of less than 100 µs now seem possible with holographic storage techniques. To see how this is possible, consider how information is stored holographically (see Fig. 3).To begin with, the information is not stored serially as is the case with compact disks and magnetic hard drives. Instead, data are written a "page" at a time, where each page is encoded onto a laser beam by a spatial light modulator (SLM) as a two-dimensional pattern of light and dark pixels representing 1s and 0s. The encoded laser light is then focused by a lens into a light-sensitive storage material, where it interferes with a reference laser beam and forms a volume hologram (specifically, a Fourier volume hologram) of the SLM pattern.

The same page of information can be recovered (read) by illuminating the stored hologram with an identical reference beam. This reconstructs a holographic image of the original SLM pattern, which is detected by the CCD array at the back focal plane of the read lens.

If only one page of information could be stored in the crystal, the technique would hardly be worth all the research. The real potential of holographic storage is that thousands of pages of data can be stored in a volume no bigger than a dime, with each page containing megabits of information. To accomplish this, each page of information is assigned a unique reference beam, which can mean varying the angle, wavelength, or phase of the beam. Groups of holographic pages also can be separately stacked throughout the thickness of a storage medium, which would add still more storage capacity.

Another important advantage to holographic storage is its redundancy, which results from the fact that each element of a single holographic image is distributed over the entire exposed volume of the storage medium. Thus, discrete defects in the storage medium will affect the signal level of the overall data page but will not obliterate individual data bits. This enhances the integrity of the stored data.

Still another advantage, random-access speed, is a direct result of the optical nature of the holographic process. If data pages are defined by reference-beam angle, then each page can be written or retrieved as fast as the beam angle can be changed. Acousto-optic beam scanning can therefore lead to very fast data access.

Photorefractive materials

Much of the research on holographic storage has concentrated on the development of suitable light-sensitive materials, and some of the most promising of these are those that display the photorefractive effect (see photo at top of this page). When light of uneven intensity irradiates a photorefractive substance, mobile charges (electrons or holes) within the material migrate away from the brighter regions and toward the darker regions. The charges will continue to migrate in this way as long as the intensity pattern persists, thus leaving behind fixed positive or negative charges in the lighter regions. The resulting charge imbalance sets up a strong electric potential (up to 10,000 V/cm) between atoms of the two regions, which distorts the crystal lattice and changes the refractive index of the material.

If the two laser beams of a holographic storage system converge inside the volume of a photorefractive material, the resulting charge migration caused by the standing interference pattern will change the refractive index of the material and form a volume phase hologram. The most important criterion, however, is that the charges remain trapped in their new positions after the beams are turned off, otherwise the stored hologram would gradually fade away as charges diffuse back to their original homogeneous state.

The trapping of charges within photorefractive substances is a major topic of research on holographic storage materials, especially because the ideal storage material should also be erasable. Erasure of photorefractive holograms is easily done by irradiating the medium with a strong, uniform light source, which remobilizes the trapped charges and returns them to their normal uniform distribution. To avoid accidental erasure, then, photorefractive storage materials should be kept in the dark. Of course, this is impossible to do when writing or reading thousands of holograms stored in a single volume. The act of reading a single hologram can erase or degrade all of them.

Nevertheless, the prospect of storing terabytes of information in a volume the size of a small coin seem less far-fetched than ever before as the nature of photorefractive materials becomes better understood and more sophisticated holographic read/write methods are developed. Meanwhile, the strong advances now being made in high-density SLM and CCD arrays may soon give us computers with storage speeds that rival their processing speeds. n

FURTHER READING

William Saffady, Optical Storage Technology 1992: A State of the Art Review, Meckler Publishing, Westport, CT (1992).

Glenn T. Sincerbox and James M. Zavislan, eds., Selected Papers on Optical Storage, SPIE Milestone Series, v. MS 49, SPIE Optical Engineering Press, Bellingham, WA (1992).

Glenn T. Sincerbox, ed., Selected Papers on Holographic Storage, SPIE Milestone Series, v. MS 95, SPIE Optical Engineering Press, Bellingham, WA (1994).

Judith Paris Roth, ed., Rewritable Optical Storage Technology, Meckler Publishing, Westport, CT (1991).

Jordan Isailovic, Videodisc and Optical Memory Systems, Prentice-Hall Inc., Englewood Cliffs, NJ (1985).

About the Author

Thomas V. Higgins

Contributing Editor

Thomas V. Higgins was a contributing editor for Laser Focus World, covering science and technology.