NONLINEAR OPTICS: Quasi-phase-matched DFG lasers for sensing enter the market

JAMES J. SCHERER

Advances in telecom-derived solid-state-laser technologies are now being combined with advances in nonlinear optical materials to produce frequency-agile commercial mid-infrared laser sources via difference-frequency generation (DFG). The 3 to 4 µm spectral region, in which commercial DFG lasers now operate quite effectively, is particularly desirable because it is not accessible via quantum-cascade (QC) laser technology and has historically been covered only by cryogenic lead-salt and complex and expensive optical-parametric-oscillator (OPO)-based laser systems.

New developments in both congruent and doped periodically poled nonlinear materials-most notably lithium niobate (LN) and magnesium-doped LN-are being combined with diode, fiber, and optical-switch laser technology to produce lasers that provide truly single-frequency, single-transverse-mode, and broadly tunable infrared (IR) light. In addition to conventional DFG lasers based on mixing two fiber amplified diodes in a single-pass configuration,1 several novel versions of DFG-based lasers have been developed, including high-speed switched multicolor versions and high-power versions. Although research on quasi-phase-matched (QPM) DFG devices has been ongoing for decades, commercialization of the technology has only recently been achieved.

All-fiber launching into PPLN

We have recently developed and packaged a turnkey commercial tunable IR DFG laser that combines polarization-maintaining architectures with all-fiber-coupled QPM materials to produce high-purity, widely tunable mid-IR laser light in primarily the 3 to 4 µm region. These lasers use congruent as well as magnesium-oxide-doped periodically poled LN (MgO:PPLN) crystals in configurations that produce hundreds of microwatts to milliwatts of power. The systems use all-fiber-coupled architectures in which solid-state lasers (primarily diode and fiber based) are first combined in fiber before being launched into suitably poled nonlinear media. Tuning the wavelength of either or both of the near-IR lasers results in tuning of the middle IR, in essentially the same fashion that telecom-derived distributed-feedback diode lasers are tuned via a simple current ramp.

When using MgO:PPLN, higher-power versions are achieved by scaling the pump-source powers. One such prototype system achieved 25 mW of tunable output by using a novel pump-enhanced architecture. In this system, nearly a factor of two in continuous-wave output power was achieved in the MgO:PPLN material compared to the congruent PPLN, which is believed to be primarily due to a combination of reduced intrinsic absorption and beam distortion.

A two-color version of this commercial DFG system that we have developed for researchers at Stanford University (Palo Alto, CA) uses a high-speed optical switch, thereby enabling two interleaved mid-IR wavelengths to be generated and rapidly modulated in two relatively widely separated spectral regions (see Fig. 1). Broad separation of the two wavelengths was achieved by exploiting specific PPLN periods and temperatures wherein a relatively broad spectral region can be phase-matched for three lasers simultaneously at a single crystal temperature. The result is a mid-IR laser that produces two colors in an interleaved fashion at a repetition rate of up to 200 kHz, which is advantageous for determining spectral contrast (such as absorption) in transient chemical systems. This system achieved nearly a milliwatt of multicolor laser light, which is suitable for many sensing applications. In addition to multicolor and high-power systems, systems with continuous tuning ranges spanning hundreds of nanometers have been developed.

Sensor applications for QPM-based DFG lasers

Sensor applications for high-purity mid-IR lasers are numerous, including in situ trace-gas sensors based on conventional absorption and optical-cavity enhanced-absorption, IR lidar, and photoacoustic sensors. For example, NovaWave’s commercial DFG-based platform is being used in compact greenhouse-gas sensors based on simple conventional absorption spectroscopy. Initial sensor systems will target the two primary greenhouse gases: methane and carbon dioxide. Methane is accessed via its well-known absorption spectra in the 3.5 µm region, while carbon dioxide will be monitored via its spectral fingerprint in the 4 µm region.

The advantage of monitoring both of these species via their associated middle-IR “fundamental” vibrational spectra (as opposed to the more common 1.5 µm region “overtone” bands) lies in the associated significant increase in the absorption intensity. For the specific case of carbon dioxide, the mid-IR absorption strength is nearly 10,000 times stronger than the associated overtone transitions. As a result, centimeter-scale direct-absorption cells can be used, which makes extracting absolute concentrations straightforward. Prior IR laser sources in the 3 to 4 µm spectral region are cumbersome to use or require liquid nitrogen, which makes them unsuitable for autonomous field applications. In contrast, a commoditized low-cost mid-IR laser opens the door for several very important sensor applications, such as those related to global warming.

No optical cavity

To effectively monitor fluxes of methane and carbon dioxide, highly precise and accurate measurements are required for extended periods of time over a wide range of environmental conditions. An important advantage of single-pass DFG-based laser systems over OPO lasers is that they possess no optical cavity and, hence, are not subject to frequency mode hops, except for those that can occur in the near-IR diode lasers used in the mixing process. Because near-IR diode sources-including distributed-feedback and distributed-Bragg-reflector devices-have been engineered to the point of operating essentially mode-hop-free, the resulting DFG-laser frequency is similarly stable and reproducible on a day-to-day basis, which is critical for reducing sensor complexity.

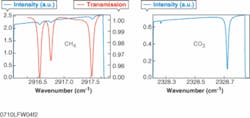

In one example, DFG-laser-based sensors obtain mid-IR absorption spectra for methane in the 3.4 µm region and carbon dioxide in the 4.3 µm region (see Fig. 2). These sensors could be placed into an existing global network of monitoring stations to accurately determine fluxes of greenhouse gases in, for example, urban centers, forests, or wetlands. Such measurements will be critical to understanding the sinks and sources of greenhouse gases; an all-optical approach reduces consumables and provides real-time data.

Industrial-sensing applications for mid-IR DFG-laser-based sensors are numerous, and include hydrocarbon sensing in the oil and gas industries, semiconductor-process gas monitoring, homeland defense, and medical diagnostics. A significant advantage of such lasers includes the ability to leverage the ever-increasing number of diode lasers and fiber lasers that are becoming available in the marketplace, with similarly higher output-power milestones being achieved on a regular basis. This, in turn, enables new wavelength regions to be accessed using consumer off-the-shelf commodity lasers via proper selection of the QPM material.

While single-frequency QC and interband-cascade laser technology may indeed ultimately access the 3 to 4 µm region with high wavelength purity similarly to that now available with new commercial DFG lasers, QC epitaxy technology is still relatively complex and issues such as device yield and hitting the target wavelength are still significant. Difference-frequency-generation lasers, on the other hand, use well-established and reliable near-IR diode sources that present no problems for scaling into mass markets. Additionally, mixing fiber-coupled near-IR laser sources produces nearly pure TEM00 mid-IR DFG light, which provides many benefits when imaging into optical multipass cells, for example. Nonetheless, while further development of QC technology is likely, DFG technology should remain competitive for the foreseeable future. Moreover, as advances in nonlinear materials continue, DFG technology will become competitive with QC technology in terms of both output power and wavelength coverage. In the last few years, waveguide PPLN devices, for example, have provided single-frequency-laser powers in the 15 mW regime, which is on par with that of single-frequency QC lasers.

New QPM materials, new wavelengths

In addition to well-established and commercially available ferroelectric nonlinear materials such as PPLN, it is anticipated that next-generation so-called “zinc-blende” semiconductor materials such as optically patterned gallium arsenide will improve laser-output powers, as well as extend spectral coverage into the longer-wavelength IR region. As the nonlinear coefficient of such materials is as much as five times that of LN, such a material could potentially replace PPLN altogether, with associated increases in power as well as extended spectral coverage.

Researchers at Stanford University, Thales, Sandia, and Hanscomb Air Force Base have pioneered the development and application of such materials, demonstrating their efficacy for accessing wavelengths into the 11 µm region.2, 3 Challenges to integrating these materials into the commercial marketplace primarily include developing lower-cost, parallel manufacturing methods. Once this problem is addressed, truly turnkey, fieldable laser systems similar to those now commercially available in the 3 to 4 µm region will likely become available over a much wider wavelength range.

REFERENCES

1. See, for example, D. Richter and P. Weibring, Applied Physics B: Lasers and Optics1 (2006).

2. L.A. Eyres et al., Appl. Phys. Lett. 79, 904 (2001).

3. See, for example, O. Levi et al., Opt. Lett. 27, 2091 (2002).

Tell us what you think about this article. Send an e-mail to [email protected].

JAMES J. SCHERER is president and CEO of NovaWave Technologies, 900 Island Drive, Redwood Shores, CA 94065; e-mail: [email protected]; www.novawavetech.com.