TERAHERTZ OPTICS: Grooved aperture efficiently couples terahertz waves into wire waveguide

Metal wires can serve as waveguides for terahertz radiation (see www.laserfocusworld.com/articles/279833); if sharply pointed, the end of such a waveguide can even focus the radiation to a subwavelength-size spot. Coupling terahertz radiation to a wire, however, is difficult. Researchers Amit Agrawal and Ajay Nahata of the University of Utah (Salt Lake City, UT) have developed a simple technique that efficiently converts free-space broadband terahertz pulses to multicycle narrowband terahertz pulses traveling down a wire.1

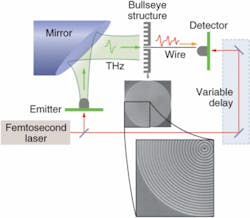

In their setup, the end of the wire waveguide is inserted into the center of a circular subwavelength aperture in a metal disk (see figure). Cut into the disk itself are up to 25 concentric grooves equally spaced in a bullseye pattern, which captures the radiation and couples it into the wire.

The interesting thing about the technique is the relation between the grooves in the disk and the properties of the resulting waveguided pulse. The free-space incident pulse is only a single cycle long, and is therefore very broadband; however, the waveguided pulse is narrowband, with exactly as many cycles as there are grooves in the disk. This occurs because the disk receives the broadband pulse in one blast; each groove then sequentially transfers its own version of the pulse toward the wire in the form of a surface oscillation, resulting in a series of cycles (and therefore a narrower spectral line).

For wire waveguides, the researchers used 6-cm-long commercially available sewing pins, which had a 700 µm diameter and were tapered to 200 µm at one end. The bullseye structure consisted of a 150-µm-thick freestanding stainless-steel foil; the grooves were 100 µm deep and had a 1 mm period, which corresponds to a 0.3 THz transmission resonance. The hole in the middle was 490 µm in diameter. The researchers set up a few control experiments as well; these included using a short 1 cm wire, replacing the 25-groove aperture with a two-groove aperture, and using an aperture with no grooves at all.

Narrowband peak

A modelocked Ti:sapphire laser operating at a wavelength of 820 nm and a pulse rate of 89 MHz was used to create terahertz pulses from a photoconductive emitter. A terahertz detector was placed near the end of the wire, offset by 3 mm from the wire’s axis (testing at different locations confirmed that the measured wave was radially polarized). The output spectrum for the 25-groove aperture shows the expected narrowband peak, while the two-groove version shows a smaller, wider spectral bump.

Replacing the sewing pin with the 1 cm wire resulted in no coupling, and also showed that no significant free-space radiation was transmitting through the aperture to contaminate the experimental results. In addition, when using the longer wire, moving the tip of the wire from within the aperture to a mere 50 µm outside of it caused the coupling to cease, showing that the coaxial geometry is a necessary condition for coupling.

Potential applications include terahertz spectroscopy and near-field imaging. “The resolution of a near-field imaging device directly depends on the spot size of the focused incident radiation and also on the tip size of the metal probe,” says Agrawal. “In this technique, the metal wire would act as the probe, in analog with conventional near-field techniques. Recently, it has been theoretically demonstrated that by tapering the end of the metal-wire waveguide, it is possible to concentrate terahertz radiation to subwavelength spot sizes of about 25 µm.2 Because the wavelength of terahertz radiation is on the order of 300 µm (for 1.0 THz), such small lateral spatial resolution cannot be achieved using conventional terahertz near-field techniques.”

REFERENCES

1. A. Agrawal and A. Nahata, Optics Express 15(14) (July 9, 2007).

2. S.A. Maier et al., Phys. Rev. Lett. 97, 176805 (2006) and J.A. Deibel et al., Proc. IEEE, in press (2007).

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.