CPM enables sizing of submicron particles

Raimund Barden and Rainer Peters

The rapid growth of life-science research has increased the need for fast, accurate instruments capable of measuring the size of biomolecules and organic solids as small as 1 nm in suspension over a wide concentration range. Traditional light-scattering instruments are unable to meet all of the conflicting requirements, but a new technique called noninvasive back scattering offers a compact, reliable solution. Implementing this technique requires a photon detector capable of distinguishing between closely spaced photon arrivals so that sophisticated autocorrelation routines can be run. Conventional photomultiplier tubes (PMTs) generate afterpulses that mask the later photons, but the new device—the channel photomultiplier (CPM)—produces a clean signal perfectly suited to the requirement.

Dynamic light scattering

Very small particles in solution cannot be observed directly by optical microscopy because of the wavelength-dependent diffraction limit. Typically, optical microscopy begins to fail when the particles to be measured fall below 1 μm, becoming completely incapable in the deep submicron range. Dynamic light scattering (DLS), which uses a measure of the diffusion coefficient distribution of particles in solution, can accurately measure these particles, spanning a range reaching down to 1 nm.

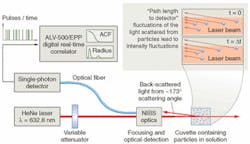

The diffusion coefficient measurement is performed via analysis of the temporal fluctuation of light scattered from the sample—the particles in solution in an appropriate glass cuvette—under a given scattering angle while illuminated by a coherent light source. The scattered light intensity is constant for a nonmoving system of particles, but the particles in solution get slightly displaced from each other as a result of Brownian motion. For any given small time interval, this leads to small phase changes in the scattered light amplitude from each particle, or, if all such contributions are summed up and presented as an intensity at a light detector, to fluctuations in the resulting intensity. Because, given a specific optical setup, the average phase changes per time interval depend solely on the average diffusion coefficient, analysis of the temporal fluctuation of the scattered intensity can provide information on this coefficient (see Fig. 1).

Analysis of the temporal fluctuation of the light intensity is usually performed via the computation of an autocorrelation function (ACF) of the measured light intensities. For a single particle-size class in solution, the field ACF shows exponential characteristics. The smaller influence of multiple scattering effects at large scattering angles, the ability to measure both transparent and absorbing samples, and the reduced susceptibility to "dust" due to the decreased scattering for particles much larger than 1 μm make backscattering the geometry of choice for high-performance particle sizing. Unfortunately, large scattering angles also mean large scattering vectors, forcing the lag time and, therefore, the maximum allowed sampling time for the autocorrelation measurement well below 1 μs for a 1-nm particle in solution.

Further, the overall scattering and optical detection process (which is required to be highly coherent to preserve the phase changes) leads to a photon rate seldom exceeding one million scattered photons per second (approximately 0.3 pW) for such a small particle. Because analog techniques are unable to operate at the required bandwidth at this low signal level, single-photon detection must be used.

Single-photon detector requirements

Several aspects of a single-photon detector are of importance for DLS. Because an ACF of the pulse stream generated by such a detector is computed from a nonlinear function, the detector not only needs to have excellent linearity, but also freedom from internal pulse-to-pulse correlations. Any inherent correlation of the detector becomes visible in the resulting ACF and will add uncertainty to the measurement. In addition, high quantum efficiency and low dark count are required.

Before the channel photomultiplier (CPM) was introduced, classical PMTs and single-photon-counting avalanche photodiodes (APDs) were most often applied to DLS measurements. Both of these devices exhibit the typical problems of single-photon detectors—dead time and afterpulsing. During the dead time, which follows each photon detection event, the sensor is blind to further incoming photons. After the photon-generated pulse is detected, accumulated charge in the detector can create an afterpulse that can be mistaken for a real photon arrival. Both of these effects increase the minimum interval between permissible successive measurements and thus set a minimum, generally above the ideal, on the ACF lag time. Various methods have been implemented to compensate somewhat for the performance shortcomings of the PMT and APD devices in this application but, clearly, a more appropriate device is desirable.

The channel photomultiplier

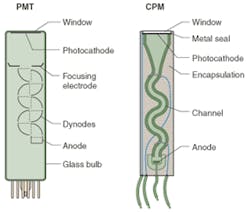

The CPM is an improvement on the classical photomultiplier tube that conserves the advantages of the PMT while avoiding its disadvantages (see Fig. 2). In the PMT, photons enter via a transparent faceplate, where some are absorbed by the photocathode from which photoelectrons are emitted into the vacuum. A high voltage applied across the photocathode and the first electrode accelerates and focuses the photoelectrons onto a specially coated electrode called a dynode. At each collision of an electron with the dynode coating, several secondary electrons are created. These secondary electrons are accelerated onto the next dynode and more secondary electrons are generated. This multiplication is repeated up to 10 times, producing gain on the order of one million. To produce this gain, each dynode must be electrically isolated from the others and supplied with its own voltage.As in the PMT, photons entering the CPM produce photoelectrons that are accelerated into the vacuum toward the anode by an electrical field. In the CPM, however, a single hollow glass tube coated internally with a semiconductor replaces the complicated multielement dynode structure needed in a PMT. Electrons hitting the inner wall produce secondary electrons that continue to travel down the channel. At each subsequent collision with the wall, there is a further multiplication of the secondary electrons. Ultimately, an electron multiplication of 100 million or more can be obtained. The resulting current can be read out at the anode. Unlike the PMT dynode structure, the CPM channel requires only one applied voltage. Further, The CPM is more mechanically robust than the PMT and much more resistant to the influence of external magnetic fields.

One result of this simple structure is the improvement in vacuum inside the device. The CPM, manufactured under ultrahigh vacuum conditions, presents a smooth glass surface for outgassing during the manufacturing process. The combination of ultrahigh vacuum and the bent-tube configuration prevents generation of ion currents responsible for the afterpulsing in PMTs.

The CPM technology also produces very low background counts because the channel, unlike the dynode assembly, is virtually silent. Dark count rates from the channel on the order of 0.01 counts per second (cps) are common and negligible. In contrast, PMT background counts originating from the dynode structure are usually significant in the total dark count. In the CPM, nearly all background counts result from thermal electron emission from the photocathode. Because of the absence of dynode background counts, a clean separation of the photoelectron events from the electronic background noise can be performed by the discrimination electronics resulting in high stability of the signal over time. Because the CPM is manufactured as a monolithic semiconducting channel structure, there is no external glass bulb to charge and discharge. Consequently, the background is extremely stable and free of noise bursts common in the PMT.

Application to particle sizing

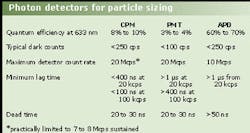

The particle-sizing application requires a detector with certain performance requirements in quantum efficiency in the red, photosensing area, speed, noise floor, signal fidelity, and dynamic range. A summary of the characteristics of the best-fit devices of each type reveals the advantage of the CPM (see table).The combination of increased signal from a photocathode optimized for high quantum efficiency at the 633-nm laser wavelength and the inherent response speed of the CPM structure confers on the CPM a significant improvement in autocorrelation performance compared to the PMT. Although the APD has even higher quantum efficiency the high lag time and the high dead time cancels this advantage for smaller particle sizes. The dark signal for all three devices is comparable in this application.

A CPM module is used as a single-photon detector in a high-performance particle sizer made by ALV Laser, replacing a classical PMT (the noninvasive backscatter technology has now been licensed to Malvern Instruments, Malvern, England). The instrument uses an autocorrelator with a minimum sampling/lag time of 125 ns. The CPM performance advantages substantially broaden the instrument's measurement ranges. Small-particle size measurements can be performed more than twice as fast, measurements can be made on samples with 60% lower particle concentration, and smaller particles can be measured. With a CPM installed, the instrument can easily and accurately size lysozyme (the protein researcher's workhorse, around 4.1 nm hydrodynamic radius) down to 0.5 mg /ml, requiring no more than 40 μg of protein.

RAIMUND BARDEN is R&D manager of the channel photomultiplier line at PerkinElmer Optoelectronics, Wenzel-Jaksch-Strasse 31, D-65199, Wiesbaden, Germany. RAINER PETERS is R&D manager at ALV Laser GmbH, Robert-Bosch-Strasse 46, D-63225, Langen, Germany; email: [email protected] and [email protected].