Dots in a well detect thermal infrared photons

Direct-bandgap mercury cadmium telluride (HgCdTe) imagers operating in the 8- to 12-µm atmospheric window allow remote sensing of living creatures, hidden fires, and other heat-emitting entities. Such imagers are, however, difficult to manufacture so that they have a uniform response for all pixels. Researchers at the University of New Mexico (UNM; Albuquerque, NM), the Air Force Research Laboratory (Kirtland Air Force Base, NM), and the Army Research Laboratory (Adelphi, MD) are taking an alternate approach with material that lets them fabricate their detectors using mature gallium arsenide (GaAs) technology, resulting in uniform response.1

null

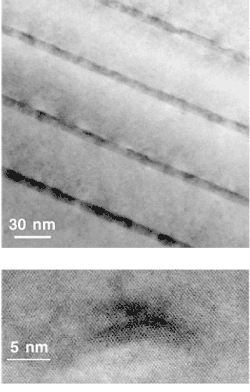

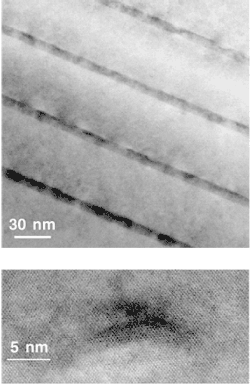

The detectors are made of indium arsenide (InAs) quantum dots placed in an InGaAs well; the well sits within a GaAs matrix (see figure). The dots, which are a few nanometers in size, are scattered in the well at an areal density of approximately 1 × 10-11 dots/cm2—a density of about 1 electron/dot. This density was deemed optimal by the researchers after a study of different doping levels.

"The two-dimensional well increases the effective fill factor for the device," says Sanjay Krishna, one of the UNM researchers. He notes that the quantum well in a "dots-in-a-well" laser was shown to funnel carriers into the laser's quantum dots. The researchers believe that a similar mechanism, due to the change in the effective refractive index, could be raising the collection efficiency for the photons in the detector. "However, we don't have any experimental evidence yet to prove this," says Krishna.

The detectors, which are cooled to 78 K, peak in sensitivity at a 7.2-µm wavelength and have a broad spectral width of 35%. Devices with diameters ranging from 25 to 300 µm were fabricated for topside illumination. At their peak wavelength, the detectors have a responsivity of 3.58 A/W and a detectivity of 2.7 × 109 cm Hz1/2/W, which researchers claim is higher than any other quantum-dot infrared photodetector. These performance figures are still two orders of magnitude lower than those for HgCdTe detectors, however. "What the [dots-in-a-well] detectors may be able to do is decrease the fixed pattern noise in a focal-plane array," says Krishna.

The researchers are trying to push the operating wavelengths of the devices to about 8.5 to 9 µm, notes Krishna. The detectors would then become useful in the 8 to 12-µm atmospheric window, where thermal imaging is king.

REFERENCE

- S. Raghavan et al., Appl. Phys. Lett. (Aug. 19, 2002).