Academia-industry collaboration feeds exponential growth curve

The European Organization for Nuclear Research (CERN; Geneva, Switzerland) celebrated its 50th anniversary this year, which also happened to be the 25th anniversary of the first use of silicon strip detectors in high-energy particle tracking and vertex experiments, also at CERN. The early detectors were on the order of 700 mm2 in surface area, while detectors currently under construction for deployment in the next few years range in size from 70 to 210 m2. Similar technology was originally proposed for space-based high-energy astrophysics experiments about 20 years ago, and these detector sizes have grown from 500 mm2 in the 1990s to an 80-m2 device currently under construction and scheduled for launch in 2007.1

Even though these applications of silicon detectors have fallen entirely within the realm of pure science, they have still achieved exponential, “Moore’s Law” growth rates in detector area and readout channels, and in sophisticated multidimensional detector architectures, while also achieving exponential decreases in cost, largely due to ongoing fruitful collaborations between academia and industry. Potential commercial applications in areas such as medical imaging and x-ray crystallography indicate that healthy growth rates are likely to continue.2

High-energy physics

The first silicon strip-detector design was tested in the NA11 experiment on the super proton synchrotron (SPS) at CERN. The aim of the NA11 experiment was to observe and study charmed quarks, with an electronic charge of +2/3, produced in high-momentum collisions of counter-propagating proton and antiproton beams.

The original detector design consisted of a 400-µm-thick, 24 × 30-mm silicon wafer upon which metal electrodes divided into strips were deposited at a pitch of 100 and 200 µm. The electrodes were connected to an analog readout system consisting of hybrid preamplifiers and standard analog-to-digital converters. High-resistivity, n-type silicon was used because it maximized charge collection while minimizing leakage currents.3

Early seminal developments contributing significantly to the widespread adoption of this technology for use in high-energy physics included the discovery, at about the same time, that standard planar fabrication processes based on high-temperature oxidation methods would not damage high-resistivity silicon. Also of importance, was the development just a couple of years later of high-density application-specific integrated-circuit (ASIC) readout systems coupled directly to the detectors.

These developments enabled the silicon vertex-detector paradigm, embodied in the early 1980s by the Mark2 detector in the linear collider at Stanford Linear Accelerator Center (SLAC; Stanford, CA). In the Mark2, concentric layers of silicon strip detectors, arranged around the axis of the accelerator beam line, detect the trajectories of multiple emitted particles from a collision and trace them back to the “vertex” of the original event (see Fig. 1).

The functional strength of silicon for high-energy particle physics as well as astrophysics (due in part to a small diffusion coefficient and high ionization loss density) lies in the ability to detect passage of charged particles with micron-scale spatial resolution. Practical advantages of silicon include manufacturing yields high enough to actually make large devices cost-effectively, and enough radiation tolerance to make detectors with acceptable durability.

Key production parameters to control while still maintaining high yield include the doping of junctions, the homogeneity of the oxide, and the segmentation on the wafer surface that is required to produce large quantity of data-readout channels, said Eduardo do Couto e Silva, a staff scientist in the particle astrophysics group at SLAC. The achievement of such yields, as well as planar fabrication processes and ASIC readout technologies have obviously benefited from advances in semiconductor technology.

Other technology areas have also contributed. Technology development at Hamamatsu, for example, (including a long-term research collaboration with the University of Hiroshima) focused on demand for commercial detectors, such as optical-scanner photodiodes to read barcodes at retail cash registers, has also spearheaded the development of the large wafers needed for large silicon strip detectors, according to Hartmut Sadrozinski, a professor at the Santa Cruz Institute for Particle Physics at the University of California, Santa Cruz. Hamamatsu made its initial silicon strip detectors on 2- and 3-inch wafers, then moved to 4-in. wafer process lines in 1986 and a 6-in. process in 1998.4

Strip-detector technology is rapidly outstripping the wildest dreams of even the most fanatical barcoders, however, as clearly exemplified in ongoing development and construction of the silicon strip tracker (SST) for the compact muon solenoid (CMS), on the underground, 27-km-circumference large hadron collider (LHC) scheduled for completion in 2007 at CERN. The completed SST will consist of 24,244 silicon sensors with a combined surface area of 210 m2 and about 10-million data-readout channels.

More variety, more size

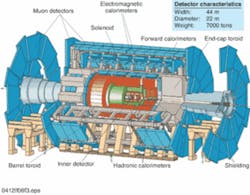

The vertex-detector paradigm for silicon strip detectors has continued to shift with development of ring-shaped hadron colliders of increasing size and with increasingly more energetic particles, Sadrozinski points out. In addition to vertex detection, silicon strip detectors are now also providing full tracking detection to include momentum determination of particles in the magnetic field. Detectors have become so large that electronics, cabling, and cooling have been brought inside the active volume and radiation-hardened, and detector module designs now have to compensate for the inclusion of electronic noise.Moving radially outward in the ATLAS detector from the central beam line in which the counter-propagating proton beams collide, one first encounters the pixel detectors that are closest to the beam line. Unlike strip detectors, the pixel detectors provide two-dimensional localization and are also necessary for rapid particle-detection rates. Data from the pixel detectors enables the detection system to determine whether the particles passing through originated in the actual collision or from the decay of a “parent” particle that also came from the collision.

In general, pixel detectors are characterized by a large number of readout channels, according to Sadrozinski, but the specific detector configurations that provide pixellated information include many components:

- drift detectors, in which one of the two spatial coordinates (along the drift coordinate) is determined by the measured drift time of charged particles through the detector;

- CCDs, which require long readout times while charge shifts across rows and columns;

- hybrid pixel detectors, which are essentially strip detectors with reduced area of the order of 50 × 300 µm per pixel; and

- monolithic active pixel detectors, which essentially apply the CMOS circuitry principles found in commercial digital cameras to the data gathering needs of high energy physics.

Continuing to move outward from the beam line on the ATLAS, one encounters silicon strip detectors that provide a third dimension of position measurement for determining particle trajectories. At the outer section of the ATLAS inner tracker one finds drift detectors that in this case are not silicon but consist of gas-filled tubes with metallized walls and a single wire running along the center of each tube. A large voltage drop between the wire and the wall enables these tubes to precisely locate the trajectories of charged particles passing through them.

Upcoming astrophysical experiments involving record-sized silicon detector systems include the second alpha magnetic spectrometer (AMS-02) with about 6 m2 of silicon detector-surface area and the Gamma Ray Large Area Space Telescope (GLAST) with about 80 m2 of silicon detector-surface area, scheduled to launch in 2005 and 2007, respectively.

Even if silicon detectors for basic science applications do not continue to grow larger, exponential growth of the technology for terrestrial commercial applications are likely to follow a similarly healthy growth curve as researchers continue to adapt silicon detector technology for low-dose medical x-ray imaging, and as the continued development of 3-D silicon detectors promises more efficient yields for large-sized detector systems, as well as new and powerful tools for x-ray crystallography.

“Moore’s law is a law of human endeavor,” Sadrozinski said. “Scientists realized there was a need for this kind of detector, and then industry made them large (looking toward 12-in. wafers in the future) and supplied them at a price we could afford.”

REFERENCES

- E. do Couto e Silva, Nucl. Instrum. Meth. A 473, 107 (2001).

- 1. H. Sadrozinski, IEEE Trans. Nucl. Sci. 48 (4) 933 (2001).

- M. Turala, presentation at 5th Int’l. Symp. on Development and Application of Semiconductor Tracking Detectors, Hiroshima, Japan (June 14-17, 2004).

- K. Yamamoto, K. Yamamura, K. Sato, K. Kosugi, presentation at 5th Int’l. Symp. on Development and Application of Semiconductor Tracking Detectors, Hiroshima, Japan (June 14-17, 2004).

- http://atlas.web.cern.ch/Atlas/Welcome.html

About the Author

Hassaun A. Jones-Bey

Senior Editor and Freelance Writer

Hassaun A. Jones-Bey was a senior editor and then freelance writer for Laser Focus World.

![FIGURE 1. The design of the Mark2 vertex detector at Stanford Linear Accelerator Center established a paradigm for vertex detectors constructed of concentrically arranged silicon strip detectors [1]. FIGURE 1. The design of the Mark2 vertex detector at Stanford Linear Accelerator Center established a paradigm for vertex detectors constructed of concentrically arranged silicon strip detectors [1].](https://img.laserfocusworld.com/files/base/ebm/lfw/image/2016/01/th_165108.png?auto=format,compress&fit=fill&fill=blur&q=45?w=250&width=250)