Low-cost VCSEL swept source for OCT relies on self-heating, needs no MEMS

A vertical-cavity surface-emitting laser (VCSEL)-based, wavelength-swept laser source for optical coherence tomography (OCT) developed by researchers at Kookmin University (Seoul, South Korea) and Chosun University (Gwangju, South Korea) is both simple and low in cost. The self-heating sweep VCSEL (SS-VCSEL) is frequency-swept through direct ramped modulation of the laser pulses, which causes a self-heated temperature sweep in the laser and produces the desired wavelength sweep. This approach is very different from other VCSEL OCT sources that require a moving microelectromechanical systems (MEMS) mirror—instead, the SS-VCSEL is actually a stock low-cost (around $100) VCSEL designed for telecom use at 1300 nm and needs only modulation electronics.

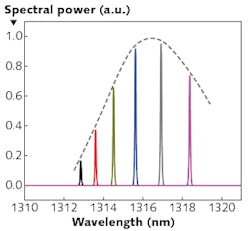

The researchers first evaluated the self-heating effect in the VCSEL as a function of modulation rate and duty cycle, and figured out that the maximum effective sweep rate was between 10 and 100 kHz. The full sweep bandwidth was 10 nm, which would result in an axial resolution of 135 μm in air for an OCT system and a full range of more than 10 cm—over 740 times the resolution, and suitable for long-range OCT imaging. The current pulses consisted of a separated sawtooth shape and an added DC bias adjusted to lead to a 50% duty cycle. An interferometric SS-OCT system was used to further characterize the swept source, showing that the tuning speed got faster toward the end of each sweep, which the researchers think is a result of a rise in the heating rate as the temperature increases. Next, OCT images of a human fingertip and a glass plate were taken to a 5 mm depth, showing good results. Reference: S. Moon and E. S. Choi, Biomed. Opt. Express, http://dx.doi.org/10.1364/boe.8.001110 (Jan. 25, 2017).

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.