Electronic imaging captures amusement-park thrills

Jerry Berger

What do people remember most from a day at their favorite amusement park? Chances are it’s that exhilarating moment when they loop upside down on a roller coaster or plunge down the flume ride into the pool of water waiting below. Now, devices such as laser sensors, charge-coupled-device (CCD) cameras, and high-speed image processing and printing systems make it possible for thrill-ride daredevils to record their memories in photographs printed on paper, on commemorative T-shirts, or on key chains.

RX Technology (New Orleans, LA) specializes in the electronic capture, presentation, and sale of pictures of people on rides in amusement parks (see Fig. 1). The company claims to be the first to offer a fully electronic ride photography system and has designed and installed ride photosystems on various types of thrill rides in 90 sites around the world. Photosystems designed by RX capture screams and smiles on suspended coasters, inverted coasters, stand-up coasters, traditional coasters, kiddie rides, and flume-like water rides. The places include Cedar Point (Sandusky, OH); the Stratosphere and New York, New York (Las Vegas, NV); Hershey Park (Hershey, PA); Opryland, USA (Nashville, TN); Paramount’s King Island (Cincinnati, OH); as well as amusement parks in the United Kingdom, Wales, France, Spain, and Japan.

The ability to capture fast-moving images and provide a high-resolution print is the main goal of the ride photosystem. Each roller-coaster car is traveling between 50 and 60 miles per hour with anywhere from eight to 18 occupants, who in some cases may be sitting back to back, according to D. Rex Gay, president of RX Technology. The photosystem must therefore synchronize flash photography and frame grabbing for everyone on the roller coaster and then send the images on to a high-tech display and selection system that allows customers to choose and purchase images efficiently and quickly as they exit a ride. Typical photo volumes run between 300 and 1000 photos in one day at an amusement park, Gay said. But record days have climbed as high as 3000.

Taking pictures

To actually take the pictures, RX Technology uses a photoelectric sensor in conjunction with a Sony DXC-9000 progressive-scan, remote video camera in most of their ride photosystems. The photosensor, provided by Banner Engineering (Minneapolis, MN), is a through-beam type using a laser transmitter on one side of the track and a receiver on the other. The source and detector are arranged such that the brake fin on each car of the ride “train” breaks the trigger light beam and signals the camera to take a shot (see Fig. 2). If it is inconvenient to mount the sensor at exactly the picture-taking point, the photosensor can be displaced up the track from the camera location and programmed with a time delay.The camera must be placed at a point in the ride that is exciting and also provides a good angle of the ride, the people on the ride, and a suitable background—all while avoiding unwanted shadows or lighting effects in the picture. In most cases, 10 to 18 pictures are taken of each train, so that there is at least one picture recorded of each rider. For some large boat rides with 24 to 28 people on a boat, a single picture plus one of the entire boat will be taken for a picture-in-picture effect.

External cables to the camera are fastened to suitable parts of the ride itself (to be as unobtrusive as possible) and fed from the camera site to the sales building where the PC, camera control unit, and RX Technology imaging equipment are housed. The photographs appear on the display monitors in the sales office where the riders can view them as soon as they get off the ride and enter the sales area (see Fig. 3). When a guest chooses to purchase a print, the order is sent to the printer and the image is printed and given to the customer. Through RX Technology’s photosystem software, logos, framing, or themed backgrounds can be added to the prints without any time delay, making the picture even more personal and fun.Gay says that RX Technology is planning to expand its successful business to new types of amusement arenas. An upcoming venture will give RX a chance to photograph skiers and snowboarders at their favorite ski resorts.

Progressive scanning

Progressive-scan imaging plays a major role in making the amusement ride photosystem possible. An interlaced scan image, provided by a traditional television camera, would provide riders with the most realistic portrayal of their motion during the ride. But because motion on video is not particularly useful for T-shirts, key chains, or commemorative prints, a progressive-scan camera system is used to provide full-frame still image resolution (see “Understanding progressive scan”).

Full-frame resolution gives a progressive-scanning system a significant advantage over a field-interlaced scanning system when the goal is to view, analyze, manipulate, store, or print a single video frame. Because single-frame analysis and enhancement are key strengths of computer-based systems, progressive scanning has been found particularly useful in computer applications—such as the ride photosystems—that must rapidly capture multiple images, store them to disk, display them for selection, and rapidly print selected images.

Understanding progressive scan

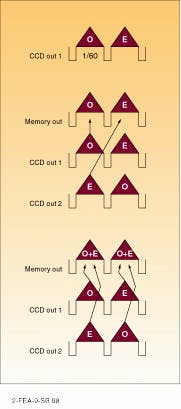

To understand progressive scan, it is helpful to separate the events within a CCD camera into two separate actions—the process of acquiring the original image, and the process of formatting this visual information to fit different output requirements. The discussion here considers three possible modes of operation: normal mode, frame-shutter mode, and VGA mode (see figure).Normal mode. A typical National Television Standards Committee (NTSC) camera uses field acquisition with interlaced field output. In this configuration, a CCD camera acquires 60 independent pictures per second. These pictures are output as 60 interlaced fields, each field containing one-half of the picture information—to result in 30 complete pictures, or frames, per second for an NTSC-compatible output signal.

The CCD imager enables variable control of the time that the photosensitive layer of the CCD is allowed to accumulate the charges created by the light of the image. In a standard NTSC-type CCD camera, for example, charges are allowed to accumulate on the photosensitive layer of the CCD imager for one field period, or 1/60 of a second (the actual exposure time can be as little as 1/2000 of a second if an electronic-shutter mode has been selected in the camera).

At the end of each field period, these charges are then transferred during the vertical interval to a storage register to create Field One of the output signal. During the next 1/60th of a second, the CCD acquires a new image that will be formatted to become Field Two of the output signal. Most NTSC television equipment, such as VCRs, monitors, and so forth, are based on a field-interlaced system.

Frame-shutter mode. Using frame acquisition with interlaced field output, a CCD camera acquires 30 independent pictures per second. These pictures are output as 60 interlaced fields, to make 30 complete pictures or frames per second. This is a progressive-scan signal, which is also NTSC-compatible.

In this operating mode, the photosensitive layer of the CCD accumulates charges once per field (or every 1/60 of a second—and again, it’s possible to limit the actual exposure time to as little as 1/2000 of a second if an electronic-shutter mode has been selected). Progressive-scan CCDs have two horizontal registers to store both the odd and even lines of a frame.

The odd and even fields are used from the same picture acquired by the camera. The odd scan lines of the complete frame are used to create Field One, while the information contained in the even scan lines is delayed by one field period and formatted to become Field Two of the complete frame. Only 30 samples per second of the original one are used, as compared to a classic interlaced system that incorporates 60 samples of the original scene.

This operating mode fits into all of the existing video switching, recording, and transmission equipment in common usage. This system is new and is not widely used today.

VGA mode. A CCD sensor is able to output information that does not comply with the NTSC television standard. In this configuration, a CCD camera acquires 60 independent pictures per second—which are output as 60 full-resolution frames per second. This is a progressive-scan signal that is VGA-compatible.

To implement such an operating mode, the CCD is configured to acquire the image during one field period. The clock used to read out the image captured by the CCD is then doubled (in comparison to that of an interlaced system), so that all of the scan lines are read out each time to form complete frames within a field period. This configuration combines the benefit of the interlaced system, which provides the appearance of smooth motion, with the benefit of a frame-based system, which produces full-resolution still frames when there is motion in a scene.