Fluorescence/Single-molecule Detection: Automated single-molecule detection: Digital ELISA for early disease detection

WILLIAM McGUIGAN and DAVID C. DUFFY

More than 50 years after the first single-molecule measurement,1 new technology is enabling fully automated detection of subfemtomolar concentrations of proteins. Thanks to its ability to offer ~1000-fold increase in sensitivity over the standard immunoassay approaches, the technology facilitates the detection and quantification of biomarkers that were previously difficult to measure. Thus, it opens the door to new applications in both life science research and in vitro diagnostics (IVD).

Let's take a look at the technology's design—including optical characteristics and details that have enabled its development—along with some clinical areas it has benefited.

Digital ELISA

Life sciences research and IVD are being driven by the challenge to detect the onset of diseases such as cancer in their earliest stages. The ability to isolate and detect single molecules is a goal of next-generation analytical techniques in genomics, proteomics, and medical diagnostics.

A new method that has proven able to isolate and detect individual protein molecules enables detection at concentrations ~1000 times lower than conventional techniques over broad dynamic ranges. Developed by Quanterix Corp. (Lexington, MA), the single-molecule arrays (Simoa) approach2 is based on an adaptation from existing bead-based enzyme-linked immunosorbent assay (ELISA) platforms.

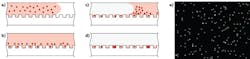

With Simoa, paramagnetic beads are coated in antibodies and used to capture proteins from a sample. These proteins are then labeled with an enzyme. Beads isolated in 216,000 fL-size microwells in the presence of enzyme substrate are imaged at high resolution to determine which beads are associated with labeled proteins and which are not. That is, the ELISA signal is digitized.

The key step to achieving single-molecule detection is the confinement of the fluorescent product in an extremely small volume via an oil seal (see Fig. 1). In conventional ELISA, the product diffuses into a large volume (~100 μL), which dilutes the signal. Confinement of single enzymes in very low volumes of substrates was first demonstrated by Rotman at Stanford Medical School in 19611, and is at the heart of the new approach: Rotman sprayed an enzyme fluorogenic substrate solution over a silicone oil, thus creating droplets in the oil that, after several hours of enzyme activity, indicated the presence of single molecules through fluorescent signals. The sprayed droplets helped confine the reaction and allow a reasonable fluorescent signal to be detected using fluorescence microscopy.

Rather than a spray can, the new technique is enabled by a micro-array structure—and the technology fully automates the process. Simoa uses a custom, wide field-of-view, fluorescence microscope to image arrays of microwells containing single molecules bound to magnetic beads.3 The use of a low-cost illumination source and a non-scientific-grade detector has given access of single-molecule detection to mainstream life scientists.

Automation and the optics inside

The U.S. office (Newbury Park, CA) of German development and manufacturing firm Stratec Biomedical develops the optical reader modules for its partners. Working with Quanterix on a platform to realize the Simoa process, the company developed a custom fluorescent microscope based on the requirements of the array and the assay protocol. Beyond the microscope, the platform involves such modules as incubators, washers, pipettors, and multiple reagents and disposables. These modules prepare the sample, as per Simoa process, for measurement. A microscope objective with a high numerical aperture (NA) images the full 3 × 4 mm array in five fluorophore bands, and facilitates the image capture/detection of single-molecule fluorescent reactions in a completely automated manner (see Fig. 2).Individual femtoliter-sized wells have nominal dimensions of 4.25 μm diameter and 8 μm center-to-center spacing. The key metric in the design of the optics is associated with ensuring the re-imaged bead intensity does not "bleed" into the neighboring well. This could lead to the calling of false positives in the bead analysis. Distinguishing two adjacent beads and limiting energy bleed is critical; in fact, this low-crosstalk requirement is the primary specification in the lens design, which is more akin to the Schuster criteria than the traditional Rayleigh criteria. Schuster's criterion states that the two point sources are just resolved if no portion of the main lobe of the diffraction pattern of one overlaps the main lobe of the other. The approach does not require diffraction-limited imaging, but the criterion that lobes or aberrations from one source should not overlap with an adjacent well is critical.

The optics design also takes advantage of image processing techniques that lessen the burden on the optics and limit the number of elements required. Color correction across all fluorescent emission bands stretching from 450 to 850 nm—while possible—is challenging in a high NA objective with a wide field of view. Color control is therefore relaxed to within individual emission bands, and the system re-focuses between bands so to correct for the axial error. The small magnification differences that result are factored into the image processing so the bead locations are well characterized.

Residual crosstalk varies primarily as a result of both aberrations—both nominal and those introduced by tolerances. Optical crosstalk also increases when signal from one well optically scatters into neighboring wells. A computational method for active correction of each array—based on analysis of the average scatter of encoded beads that have no neighboring beads—reduces the impact of this crosstalk. This technique measures the degree and direction of crosstalk in sub-regions, and accounts for this in the fluorescence images. The mathematical correction of color and crosstalk is factored in with more traditional dead/hot pixel corrections to process images for downstream analysis.

Lab on a disc

The Simoa platform uses a disc containing 24 array assemblies arranged radially (see Fig. 3). Each array contains 216,000 femtoliter-sized wells, which can contain individual beads with or without an associated immunocomplex. Designed by Sony DADC BioSciences (Salzburg, Austria; an OEM supplier of 'smart' polymer-based consumables) in collaboration with Quanterix and Stratec, the disc is manufactured using Blu-ray manufacturing processes. The microfluidic device is composed of well arrays and fluidic channels that are fabricated in separate planar polymeric parts using an injection molding technique, and then aligned and laser-bonded to form an integrated polymeric assembly. The fluidic channels and oil delivery that seal the sample were designed to ensure that no localized turbulence or air bubbles result from the fluid delivery.The arrays are imaged both at the characteristic wavelengths of the fluorescent product (to determine the presence of single enzymes) and of fluorescent dyes used to encode subpopulations of beads (to determine which bead type was present in each well). Image processing techniques are used to determine the fraction of "on" beads and the average intensity of these beads. From these numbers, it is possible to determine average enzyme per bead (AEB) independently for each bead type or protein.

The disc is a critical part of the system not only for operation, but because, as the "consumable," its cost helps determine the attractiveness of the overall technology. For the technology to be adopted in the IVD industry, for example, the test cost must be competitive with the 96 or 384 microtiter plates used in standard ELISA techniques.Clinical applications

Simoa uses the same combination of targeted antibody pairs as the standard ELISA experiments that have been common since the 1970s. Like ELISA, which has become the mainstay of immunodiagnostics, it is applicable to a wide range of life sciences and diagnostic applications.

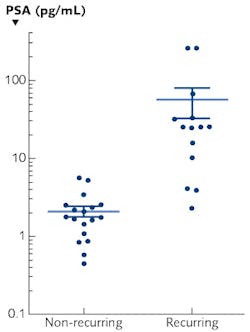

The initial applications of digital ELISA have been based on "turbo charging" ELISA, and allowing new biomedical insights from the enhanced sensitivity. In these cases, it is necessary to take, for example, a cancer-related protein, or risk factors for heart diseases, and revalidate them with the new technology. For instance, measurement of prostate‐specific antigen (PSA) following radical prostatectomy has become standard practice for monitoring prostate cancer recurrence. Quanterix has validated a PSA assay and has a very low limit of detection of 0.028 pg/mL (see Fig. 4). This assay exhibits a 3‐log improvement in sensitivity compared to the most sensitive commercially available PSA assays. The results have important implications for PSA testing in patients post-surgery, and has the potential to reassure a large subset of men that they are not at risk of recurrence.4

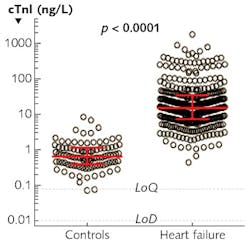

In addition, Simoa technology has been shown to measure cardiac troponin I (cTnI), which is a biomarker of cardiac damage, with both high analytical sensitivity and clinical specificity. Modest elevations of troponin are predictive of future adverse cardiac events. Studies conducted with Brigham & Women's Hospital (Boston, MA) on 362 patients with advanced heart failures and 97 healthy subjects showed a clear differentiation in Tnl levels between the two populations (see Fig. 5).5 Simoa's extreme sensitivity and full automation make it quite suitable for detection of changes in troponin concentrations after exercise stress testing and for monitoring of patients receiving medications.The next wave of Simoa applications will enable discovery of new diagnostic applications of high-sensitivity immunoassays: finding proteins and biomarkers for very "difficult" diseases. Neurological research including traumatic brain injury identification, sponsored by the GE-NFL Head Health Challenge (a partnership involving General Electric and the U.S.'s National Football League [NFL]), falls into this discovery category. In July 2015, Simoa was one of six finalists (of >400 entries) in the Head Health Challenge. The technology has proven not only that biomarkers associated with brain injury can be measured with a simple blood test, but that it is possible to quantify the severity of the trauma. The ultimate goal is a point-of-care test. NFL senior vice president of health and safety policy, Jeff Miller, has said that the winning breakthroughs "will truly advance the science around brain injury. We look forward to continuing to support this work and benefiting not only football and other sports, but society more broadly." One future goal is to eventually have Simoa available at NFL stadiums so that a fast objective test can be done to ascertain whether a player has suffered a concussion event.

In fact, the technology has already shown potential for detecting a protein biomarker for neurological damage (tau) in the approximately one-third of military personnel who deploy for combat operations and sustain one or more traumatic brain injuries (TBIs). TBI increases the risk of post-concussive disorder, post-traumatic stress disorder, and depression, but no blood tests exist for rapid diagnosis of these events. Current diagnostic tools are unable to identify individuals at greatest risk for chronic neurological deficits following TBI, but Simoa technology has enabled researchers to accurately measure participants' blood for tau, a biomarker that has been linked to longer-term neurodegeneration.6Broad applicability

Although optics and fluidics technologies have come a long way since Rotman's experiment in 1961, some common features from that approach have carried over to Simoa: spatial confinement of the protein is key (though the new technology achieves this through isolation in precision microwell structures rather than sprayed droplets) and the base microscope functionality is consistent (though fluorescent microscope architecture and componentry has advanced considerably). The microfluidic management and the degree of automation represent the biggest changes—these have enabled detection of low concentration proteins in an automated system, making Simoa a fundamental advance.

Embodied in the commercially available, fully automated Simoa HD-1 Analyzer from Quanterix (see Fig. 6), Simoa is a good example of how photonics and microfluidics have combined forces (again) to benefit life sciences. While Stratec Biomedical engineered the instrument to ultimately be used in regulated laboratories for IVD and high-throughput applications, the digital ELISA technique is currently being employed in many sought-after clinical applications in research labs around the world.

REFERENCES

1. B. Rotman, Proc. Natl. Acad. Sci U.S.A., 47, 1981–1991 (1961).

2. D. M. Rissin et al., NatureBiotechnol., 28, 595–599 (2010).

3. W. McGuigan et al., "The optics inside an automated single molecule array analyzer," Proc. SPIE, 8935, 89350X (Feb. 27, 2014).

4. H. Lapor et al., BJU Int., 109, 12, 1770–1775 (Jun. 2012).

5. P. Jarolim et al., Clin. Biochem., 61, 10, 1283–1291 (Oct. 2015); doi:10.1373/clinchem.2015.242081.

6. A. Olivera et al., JAMA Neurol., 72, 10, 1109–1116 (Oct. 1, 2015).

William McGuigan is VP of engineering at Stratec Biomedical USA, Newbury Park, CA; e-mail: [email protected]; www.stratec.com/en, and David C. Duffy is chief technology officer at Quanterix, Lexington, MA; e-mail: [email protected]; www.quanterix.com.