Fluorescence video pill camera improves cancer imaging

Typical fluorescence-based endoscopic imaging cameras consume large amounts of power and are limited to laboratory-scale applications because of their bulky size. But a new wireless fluorescence video capsule—or "pill cam"—from researchers at the University of Glasgow (Glasgow, Scotland) uses a complementary metal-oxide semiconductor (CMOS) single-photon avalanche photodiode (SPAD) imaging array and a very low-level 468 nm LED source at 78 μW to image tissue autofluorescence through fluorophore labeling while consuming only 30.9 mW of power.

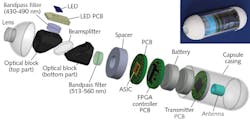

The compact pill camera incorporates the LED source to illuminate tissue, the filters to block the source excitation from the fluorescing tissue excitation, the optics to focus the fluorescent emission onto the SPAD, the electronics and digital counters to read the series of pulses from each pixel to create an array of pulse counts, and a wireless transmitter to send the data to an external radio receiver for offline data storage, image processing, and display. Among several experiments, the potential of the imager to detect cancer was simulated using porcine intestine. By binding an exogenous label fluorophore such as fluorescein isothiocyanate (FITC) to the tissue, the pill camera easily identified and imaged the fluorescent response from the diseased area, which is much higher than that of healthy tissue. Reference: M. Al-Rawhani et al., Sci. Rep., 5, 18591 (Dec. 18, 2015).

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.