Terahertz Optoelectronics: InGaAs photomixers generate and detect terahertz radiation

With contributions from the University of Leeds (Leeds, England) and the University of Manchester (Manchester, England), Researchers at TeraView (Cambridge, England) have demonstrated what they are calling the first all-optoelectronic continuous-wave (CW) terahertz photomixing system using indium gallium arsenide (InGaAs) photomixers.1 Compatible with optical-fiber excitation wavelengths, the system uses low-temperature (LT)-grown InGaAs devices for both emitters and coherent homodyne detectors.

Conventional photoconductive terahertz systems are usually based on femtosecond-speed pulsed lasers driving optical switches fabricated from LT-GaAs. In this approach, CW terahertz radiation is emitted and detected by photomixing two CW lasers in a photoconductor. The frequency difference of the lasers is tuned to the terahertz region and the conductance of the device is modulated at the difference frequency.

Although CW terahertz generation can be achieved using GaAs through LT molecular beam epitaxy (LT-MBE) and post-growth annealing, LT-GaAs is not an efficient photoconductor for excitation at optical-fiber wavelengths. Despite reports that LT growth of InGaAs would not be feasible, the team lead by Colin Baker of TeraView has succeeded in using LT-InGaAs photomixer devices to enable both the generation and homodyne detection of CW terahertz radiation compatible with the 1.06-µm laser-excitation wavelength for optical-fiber delivery.

Identical emitter and detector

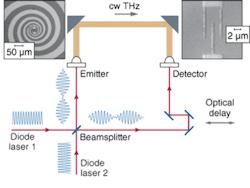

In the terahertz demonstration, two external-cavity tunable diode lasers with wavelengths around 830 nm are made collinear using a 50:50 beamsplitter and focused onto identical emitter and detector photomixers (see figure). The photoconductive InGaAs layers of the photomixers are grown on semi-insulating GaAs using molecular-beam epitaxy. The material properties that enabled the successful demonstration of the CW terahertz system were achieved by growing the InGaAs layer at a temperature of 230°C, followed by a post-growth anneal at a temperature of 450°C for 10 minutes under a nitrogen-rich atmosphere. The interdigitated fingers of the InGaAs emitter and detector were fabricated in a spiral pattern using standard electron-beam lithographic techniques.

The CW terahertz radiation is coupled out of the substrate using a 25‑mm-diameter hyperhemispherical silicon lens, producing a collimated terahertz beam. The beam travels back to the detector and the DC (steady-state) homodyne output signal is detected by a lock-in amplifier referenced to the emitter bias modulation. A time-delay stage changes the phase between the optical beat and the terahertz beam at the detector; the DC-detected signal is maximized when the terahertz beam and optical beat arrive in phase. The time delay maps out an interferogram from which the terahertz electric-field amplitude and phase are measured.

For an applied emitter bias varying between 0 and 7.5 V at a frequency of 0.4 THz, the terahertz power level varies super-quadratically with bias-doubling the source power increases the terahertz power by a factor greater than four. The team suggests that an average power of 10 nW is emitted from the biased antenna. However, because of the exceptional sensitivity of the homodyne detector, this low power is acceptable.

Currently, the LT-InGaAs devices do not perform as well as those manufactured from LT-GaAs-approximately 10 times less efficient across the entire frequency range. However, with the significant reduction in cost and size realized using conventional fiberoptic-based diode lasers and components, this short-term performance deficit may prove to be commercially acceptable.

The device is being evaluated for eventual inclusion into TeraView’s product line for pharmaceutical, security, medical, and nondestructive-testing applications that depend on terahertz radiation, notes Don Arnone, the company’s chief executive officer.

REFERENCE

1. C. Baker et al., Optics Express13(23) 9639 (Nov. 14, 2005).

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.