The environmental benefits of green energy including solar are undeniable, assuming solutions provide efficiency and cost-effectiveness. As part of this journey, it’s crucial for utilities to continually improve ongoing maintenance and monitoring practices to deliver an environmentally friendly energy source with the efficiency needed for long-term feasibility.

Being able to detect early-stage failures, degradations, defects, and faults including cracks, broken cells interconnections, and shunts is critical for the successful operation of solar cell farms. Unfortunately, when applying traditional inspection tactics to photovoltaic (PV) plants including infrared imaging, visual inspection, or a mobile lab, the approaches often lack the needed levels of accuracy and are often time consuming.

Collaborative solution

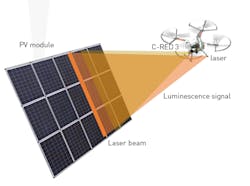

Recognizing the shortfalls, First Light Imaging (Meyreuil, France), Creative Sight (Skanderborg, Denmark), Optoprim (Vanves, France), and the Technical University of Denmark (DTU; Kongens Lyngby, Denmark) have partnered to develop an innovative drone-based solution for fast and accurate inspection of PV plants in operation called laser-induced photoluminescence imaging (LiPi; see Fig. 1 and video). LiPi is a EUROSTARS-2 labelled project co-funded by EUREKA association and the European Union Horizon 2020 framework programme.

The project brings the luminescence imaging technology onto a drone and into the field. The C-RED 3 camera, integrated in the LiPi drone solution, is an industrial-grade shortwave-infrared (SWIR) camera designed for high-end machine vision applications. It enables very high-speed, high-quality imaging (up to 600 fps in full frame) and gives its best performances at short exposure times.

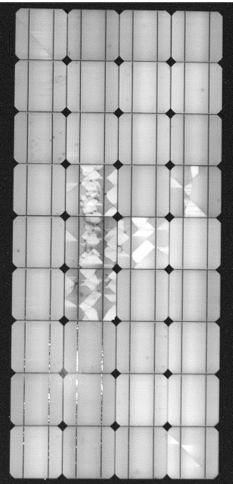

By combining a line laser with a SWIR camera, PV operators benefit from the inherent sensitivity to where silicon reemits laser light. The resulting high-resolution images can show microcracks and faults even before they become critical to energy production (see Fig. 2).

The contactless approach injects the luminescence into the solar cells, which are then captured by the SWIR camera being sensitive to the spectral region where the solar cells are emitting light. Inspection of PV modules with luminescence imaging is the future and a drone-based solution will bring a revolutionary change to the PV industry. When comparing LiPii to the traditional electroluminescence approach, it enables a wider range of contactless samples, such as partially processed wafers, while still highlighting cracks and areas of potential failure.

How it works

Fitted with the C-RED 3 SWIR camera from First Light Imaging, the system can capture full frame (640 × 512) images at 600 fps and a line laser gives high-resolution images to help in detailed fault diagnostics, enabling preventive maintenance. A high-precision GPS is integrated in the LIPI unit, making it a fully stand-alone unit that needs no metadata from the drone’s flight controller and can thereby be mounted on any drone.

The C-RED 3 camera is a compact high-speed SWIR camera, available in OEM for easy integration into a gimbal. The readout noise remains below 40 e- rms with the linear High Dynamic Range (HDR) mode, a 93 dB dynamic range, enabling the measurement of low light signals, such as photoluminescence. Windowing mode allows to achieve faster image rate (up to 32 066 fps) while maintaining a very low noise. Windowing further optimizes the compromise of framerate versus spatial resolution and adapts the image size to the PV cell dimension.

Road ahead

Proving the drone could effectively fly in a real-world environment and deliver usable photoluminescence images was the first true milestone for the collaborative initiative.

Now, the proof-of-concept project is currently seeking interest from a partner company to fully commercialize the solution.

About the Author

Peter Fretty

Vice President, Market Leader, Digital Infrastructure

Peter Fretty began his role as the Vice President, Market Leader, Digital Infrastructure in September 2024. He previously served as Group Editorial Director for Laser Focus World, Military & Aerospace Electronics and Vision Systems Design, and as Editor in Chief of Laser Focus World from October 2021 to June 2023. Prior to that, he was Technology Editor for IndustryWeek for two years.

As a highly experienced journalist, he has regularly covered advances in manufacturing, information technology, and software. He has written thousands of feature articles, cover stories, and white papers for an assortment of trade journals, business publications, and consumer magazines. He has also owned and operated numerous manufacturing companies.