Addressing autonomy gaps, one component at a time

Would you buy a car without headlights? Of course not. When making a costly investment in something like an automobile, expectations are that it will work in both daylight and nighttime conditions. This is the methodology Ian Blasch from Jabil Optics (Jena, Germany) used when discussing the company’s latest venture in developing a 3D imaging solution in collaboration with Artilux (Zhubei City, Taiwan) and ams OSRAM (Premstätten, Austria).

And rightfully so.

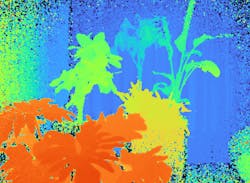

There is a known gap in the current 3D sensing market with quality solutions existing for indoor operation around 5 to 8 meters and a significantly longer range for automotive applications. Yet, within the robotics and agriculture ecosystems, there is a need for mid-range technology (approximately 20 meters).“The robotics industry has sort of started from material handling with AMRs (autonomous mobile robots), AGVs (automated guided vehicles), and autonomous forklifts from the indoor operation perspective,” Blasch says. “However, when spending thousands of dollars on a robotics platform, the industry wants to be able to do indoors and outdoors, or pass windows or open bay doors, even if you’re doing simple material handling applications inside your factory’s warehouse.”

With significant growth in automation (forecasted at 11% compound annual growth rate through 2029) driving performance improvements for robotic and mobile automation platforms in industrial environments, the opportunity exists for 3D sensor data from these innovative depth cameras to improve automated functions such as obstacle identification, collision avoidance, localization, and route planning—key applications necessary for autonomous platforms.

With this development, the Jabil Optics-led team is showcasing technologies and sensors that work indoors and outdoors to increase the utility of these platforms, with outdoor platforms rapidly heading towards autonomy. This is true whether it’s a lawn mower, last-mile delivery system, drone, or agricultural equipment doing planting, weeding, or harvesting.What’s next?

The opportunities for 3D sensing are extensive as key players continue to improve the performance, quality, and affordability. Understandably, collaboration with laser suppliers is crucial. “As all the component suppliers work towards solidifying the quality of their solutions and making them to a level for mass production, we can integrate them into the product offering,” he says. “Jabil is capturing data it’s then sending back to the suppliers, allowing the firm to serve as a nexus between the end customers for the 3D sensing and the component suppliers. We’re getting the sense of the best information to help optimize the solution for use in real environments.”

Jabil views the 3D imaging program as a success. “We are investing more in R&D to help promote areas in the industry where we believe we could help create better solutions,” he says. “In this program, we were able to demonstrate the first camera at 1130nm and one of only a few at 1380nm. It equally demonstrates the potential of industry collaboration demonstrating novel technology with the potential to dramatically improve the utility of autonomous platforms.”

About the Author

Peter Fretty

Market Leader, Digital Infrastructure

Peter Fretty began his role as the Market Leader, Digital Infrastructure in September 2024. He also serves as Group Editorial Director for Laser Focus World and Vision Systems Design, and previously served as Editor in Chief of Laser Focus World from October 2021 to June 2023. Prior to that, he was Technology Editor for IndustryWeek for two years.

As a highly experienced journalist, he has regularly covered advances in manufacturing, information technology, and software. He has written thousands of feature articles, cover stories, and white papers for an assortment of trade journals, business publications, and consumer magazines.