Photonics applications emerge for agriculture

Climate change, overpopulation, and lack of farmland and water are forcing the search for innovative agriculture methods to meet the nutritional needs of the Earth’s population while minimizing the ecological footprint. Photonics is already playing a significant role accelerating the modernization of the food industry and is paving the way for more productive, chemical-free, environmentally friendly, resource-efficient, and sustainable farming methods.

Photonics contributions to smart farming

In 2015, the United Nations adopted the Sustainable Development Goals, and one of the main goals is Global Zero Hunger,1 which will require developments in infrastructure and technology to enhance agricultural productivity.

Numbers tell a straightforward story regarding agriculture’s environmental impact. Agriculture is responsible for 70% of global water use, 24% of greenhouse gas emissions, and environmental degradation on a planetary scale.2 It is now apparent that boosting food production using current practices is unsustainable.

In recent years, a significant contribution of photonics was to provide safe, nutritious, and affordable food and establish a sustainable food industry value chain from farm to plate. More specifically, spectrometry devices and hyperspectral cameras are helping farmers determine protein levels in wheat harvests, screen for contaminants in fruits and vegetables, and observe water quality to measure the health of fish stocks, to name a few examples. Optical sensors integrated into drones, planes, and even satellites are used to map large land areas accurately and remotely. They can measure large-scale crop effects in agricultural regions and further help minimize the environmental footprint of farming practices.

Food waste is another growing concern. One-third of all food produced is wasted during harvesting, processing, distribution, or at the point of consumption. In this context, photonics is making a valuable contribution to both food production and consumption. For example, hyperspectral cameras can determine the maturity of fruits and the correct time to pick them. At the same time, imaging and labeling promise quicker food processing and distribution, while fluorescence spectroscopy can monitor amino acids, vitamins, allergens, and other components in foods at the consumption stage.

How are agriculture companies using photonics?

Big companies like FESTO and John Deere integrate optical sensors into their automation systems and heavy machinery. Notably, optical sensor-based digital solutions allow the accurate identification of insects. They can be integrated into pest management systems, including timely treatments and intelligent spraying equipment. Similarly, founded in 2018 in Innsbruck, Austria, Optronia recently introduced the Sendosafe Sensor to protect field animals from being killed by heavy agricultural machinery. In combination with machine-vision cameras and artificial intelligence (AI), their sensors detect wildlife and the cutting gear is automatically raised to prevent injury to the animal.

Vertical farming—that is, growing crops on top of each other rather than in traditional, horizontal rows—is another sector currently benefiting from optical sensors. Companies like Agricola Moderna (Milan, Italy), for example, are using photonic sensors to enhance and support their automatic control systems for environmental control, disease detection, and data collection, as well as to help them optimize processes and yield.

Hyperspectral imaging is a noncontact, noninvasive technology that provides sustainable-yet- optimized food production tools. Decisions on crop management can be based on the plant’s health and nutritional status by applying hyperspectral imaging to determine, for example, nitrogen, phosphorus, potassium, and flavonoids. Hyperspectral imaging is also used in plant phenotyping by gathering information about the plant’s chemical assets, size, and shape to optimize crop management decision-making. A pioneer in novel real-time sensing techniques (near-infrared [NIR] and Raman spectroscopy, and hyperspectral imaging) based on integrated photonics for agri-tech is OnePlanet Research Center, IMEC, based in the Netherlands. OnePlanet’s goal is to increase understanding and improve food production processes to optimize the use of resources and reduce waste streams.

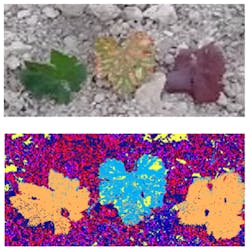

France-based SILIOS Technologies has developed a range of compact multispectral cameras. These include their CMS/CMS4 series covering the 430–930 nm spectral domain. The TOUCAN is specially designed to allow high integration of VIS+NIR multispectral systems, which splits the image into ten spectral bands on a very large range (400–900 nm). As Thierry Berthou, sales manager of SILIOS, points out, these cameras can be used to detect disease early and turn on smart spraying, thereby reducing chemical inputs (see Fig. 1).

Finnish company Specim is another developing hyperspectral imaging solutions for agriculture. One of the recent examples is within vertical farming, which can save up to 98% of soil and 95% of water required for farming.3

From the illumination side, the quartz tungsten halogen (QTH) lamp is a popular choice in hyperspectral imaging because it provides broad spectral illumination from VIS-IR to shortwave-infrared (SWIR). However, despite its relative low cost, its lifetime is low and lamp recalibration is frequent, costly, and time-consuming. Heat management dissipation is also needed, which leads to a high-power consumption, and form factor constraints limit the imaging design, size, and cost of the hyperspectral system. ICFO in Spain is studying alternative sources of SWIR illumination by using colloidal quantum dots (CQDs) to allow for flexible hyperspectral imaging solutions.

Similarly, the Swiss Center for Electronics and Microtechnology (CSEM) is developing Internet of Things (IoT) for agriculture by creating cost-effective and straightforward multispectral imaging systems that can provide an in-depth analysis of crop, soil, and water conditions (see Fig. 2). Their ultimate aim is to develop fully autonomous systems with autocalibration to help make agriculture more sustainable.AI, combined with imaging technologies (multispectral, hyperspectral, and RGB cameras), can provide solutions for monitoring plants’ growth and collecting and analyzing large volumes of data required for building optimization processes. Spectral Engines, based in Finland, uses smart spectral sensors and AI to help realize the full potential of farming operations and reach the next level of smart farming—for example, improving the quality of produced milk, enhanced soil analysis, and fertilization optimization. They aim to bring the benefits of spectral sensors and AI to all parts of the food chain, including food production, processing, logistics, and food quality measurement.

Although intelligent optical sensors and software can help farmers get real-time performance data from their production, the agriculture industry is setting increasingly stringent demands on spectrometers used inside the sensors. The units typically must be compact and robust for direct deployment on, for instance, harvesting machines, and they need to provide consistent results. To meet these challenges, Ibsen Photonics (Denmark) developed their PEBBLE NIR spectrometer (see Fig. 3)—a unit with high optical sensitivity and resolution, which is almost immune to thermal changes and vibrations, and comes in a compact form factor with no moving parts inside. A typical application for this device is to monitor chlorophyll to determine whether the plant is getting enough, too little, or too much fertilizer (nitrogen).Novel NIR spectral sensing technologies promise to unravel the underlying chemical properties of materials, unlocking many applications in smart farming such as quality control, optimizing shelf life of products, understanding the right moment for harvesting, and simultaneously determining several parameters like the ripeness, moisture level, or protein level in crops and fruits, all in real time. MantiSpectra (Netherlands) has developed a breakthrough miniaturized photonic chip, ChipSense, condensing the power of a NIR laboratory instrument into a small semiconductor device. Thanks to large-scale wafer integration, this spectroscopic chip will soon reach mass markets and play an important role in revolutionizing agriculture. MantiSpectra offers a standalone spectral sensor module that generates data to enable classification and quantification tasks for on-site or in-line noninvasive analysis. This will allow farmers, factories, food manufacturers, equipment manufacturers, and ultimately consumers to measure the quality of food without sending samples to dedicated labs and optimize food production chains. With a smaller footprint, no moving parts, and fast measurements, the sensor is ready to be integrated into existing equipment or new handheld devices.

Another company developing novel, miniaturized spectrometers is Specto Photonics, an Italian-based company established in 2019 that is about to introduce an all-optical system for measuring the 3D hydromechanical properties of living organisms, which is crucial for monitoring water content—a key parameter for monitoring plant health and assessing food quality.

Based in Rome, Italy, FLIM LABS works in fluorescence spectroscopy and fluorescence imaging. Fluorescence lifetime imaging (FLIM) microscopy can be used for in vivo monitoring of a plant’s response to herbicide or to track down different pH conditions within a plant’s cell environment.

With specific regard to agriculture, Earth Observation (EO) remote sensing provides images independent of cloud cover that can be used to provide reliable and regular assessments of extreme soil wetness conditions and crop development in spring and summer and reveal a complete picture of the farmland and crop status. This information enables early warning of unfavorable climate conditions and accurate assessments of crop damage. EO systems rely on the ability to differentiate the optical signal of interest from the noise, often using wavelength-selective optical filters. Iridian Spectral Technologies (Canada) provides a range of optical filters for use in EO. These filters can provide wavelength selectivity either as single bandpass filters or as multizone filter (MZF) arrays that can turn a single detector into a multispectral device capable of analyzing different wavelengths, making these optical filters key components in photonics-based EO instruments.

In the same concept, Chroma Technology has expanded its machine-vision product line into the SWIR range. These new optical filters transmit specific SWIR spectral bands with exceptional precision. The key features are >90% transmission, >OD4 blocking, steep transition slopes, top-hat curves, and high signal-to-noise ratio. Their offerings extend from 380 to 2800 nm and are suitable for a wide range of machine-vision and remote-sensing applications like in LiDAR, multispectral imaging, inspection, or sorting processes or agricultural sensing.

Photonics is finding applications in all aspects of agriculture—reducing the use of chemicals via smart pest control and selective spraying, reducing waste, protecting wildlife, and helping farmers shift to science-based procedures that maximize yield and profit while minimizing harm to the environment. And this technology is also playing a significant role in modernizing all parts of the food chain, from food production and processing to logistics and food quality measurement. Although these technological developments will be a critical factor in enhancing future agricultural productivity, for Global Zero Hunger to become a reality, continuing action will also be required to address other challenges affecting the global food supply chain, namely population growth, deterioration in soil quality, climate change, deforestation, production of carbon dioxide, and decreasing biological diversity.

ACKNOWLEDGMENTS

EPIC wishes to acknowledge its members and collaborators who are always eager to share their ambitions and vision, in particular Blanc Séebastien, CSEM; Thomas Rasmussen, Ibsen Photonics; Jason Palidwar, Iridian Spectral Technologies; Marcel Zevenbergen, IMEC; Thierry Berthou, Silios, Bailly Almut; Chroma Technology, Lars Benesch; Mantispectra; and Katja Lefevre, Specim.

REFERENCES

1. See https://bit.ly/3wdJa7j.

2. See https://bit.ly/39jVBoN.

3. See https://bit.ly/3wjlQnm.

About the Author

Panagiotis Vergyris

Dr. Panagiotis Vergyris is executive director at Specto Photonics (Milan, Italy). He has a Ph.D. in Quantum Photonics and more than 10 years’ experience in the photonics industry, with technical, managerial, and business roles in different deep-tech companies. Before joining Specto Photonics, he was a photonics program manager at the European Photonics Industry Consortium (EPIC), supporting startups in photonics, orchestrating successful business matches, and supporting and ensuring the viability of the European photonics ecosystem.