Basic monocular camera and LED-based communication enables autonomous vehicle-to-vehicle positioning

A critical function for autonomous vehicle navigation equipment is the ability to maintain safe vehicle-to-vehicle (V2V) spacing between two moving vehicles. While GPS is the preferred method, the GPS signal can be disrupted by the presence of tall buildings and other obstacles, and/or by multipath reflection errors. And while lidar and radar are highly effective, they are also expensive to implement. An alternative method that is both accurate and inexpensive has been demonstrated on an experimental platform created by scientists at Hunan University (Changsha, China) using a simple monocular camera and visible light communication (VLC) equipment. Not only does VLC provide vehicle-to-vehicle positioning capability, but it also provides illumination and communication functions as well.

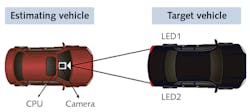

Immune to electromagnetic interference and consuming little power, the VLC equipment consists of a CPU and a monocular camera (an iPhone) mounted on the “estimating” vehicle that takes pictures of two LEDs spaced a fixed distance apart on the taillights of the “target” vehicle. Image processing, the pinhole model, and a Kalman filter algorithm is applied at the CPU to calculate the taillight positions relative to the estimating vehicle and continuously compute the V2V spacing parameters. For vehicles moving at speeds up to 22 m/s, the positioning accuracy can be maintained with centimeter-level accuracy. Reference: J. He et al., Opt. Express, 28, 4, 4433–4443 (2020).

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.