Next-generation gravitational-wave detectors require even better mirror coatings

Compared to the current optical coatings used on the Laser Interferometer Gravitational-Wave Observatory (LIGO) operated by Caltech (Pasadena, CA) and the Massachusetts Institute of Technology (MIT; Cambridge, MA), cryogenic gravitational-wave detectors such as the upcoming Kamioka Gravitational Wave Detector (KAGRA) at Kamioka Observatory in Japan and the low-frequency detector of the proposed Einstein Telescope (ET-LF) will require improved interferometer mirror coatings with strain thermal noise reduced by a factor of 25. These gravitational-wave detectors are kilometer-scale Michelson interferometers that measure changes in length caused by passing gravitational waves. Researchers at the Universities of Glasgow and Strathclyde (both in Glasgow, Scotland), the University of Hamburg (Hamburg, Germany), and Hobart and William Smith Colleges (Geneva, NY) have successfully developed low-noise mirror coatings using hafnium dioxide doped with silicon dioxide (HfO2:SiO2) and amorphous silicon rather than the current tantalum oxide (Ta2O5)- and SiO2-only coatings to achieve these next-generation mirror requirements.

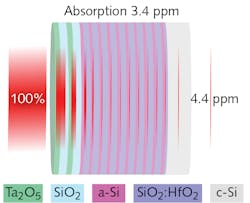

To achieve low coating thermal noise (CTN) and low optical absorption at the parts-per-million level for ET-LF, two layers of relatively noisy Ta2O5 are alternated with SiO2. These layers reflect most of the incoming light and reduce the light intensity enough to allow lower layers to be made from materials with higher absorption, but very low noise: HfO2:SiO2 alternated with amorphous silicon (a-Si) on a crystalline Si (c-Si) substrate. The SiO2 doping in the HfO2:SiO2 layers allows the coating to be heat-treated without the material crystallizing, reducing stress and further reducing the CTN and the absorption of the coating stack. While this interferometer mirror coating achieves the required factor-of-25 reduction in CTN and absorption, many other noise sources still need to be reduced to achieve a factor of 100 improvement in sensitivity over today’s LIGO instrument at frequencies around 10 Hz. Reference: K. Craig et al., Phys. Rev. Lett., 122, 23, 231102 (Jun. 13, 2019).

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.